When it comes to designing or upgrading electrical systems in industrial or commercial projects, selecting the right dry-type transformers isn’t just a technical decision—it’s a strategic one. Choosing correctly affects everything from energy efficiency and safety to long-term maintenance costs.

If you’re a project engineer, procurement manager, or electrical contractor, you already know that every transformer specification has ripple effects on performance and ROI. But with so many models—cast resin, vacuum pressure impregnated (VPI), or open wound—it can be tricky to know which one truly fits your application.

This guide breaks down what you need to know about dry type transformers, how to evaluate the right parameters, and the key factors that influence your purchasing decision.

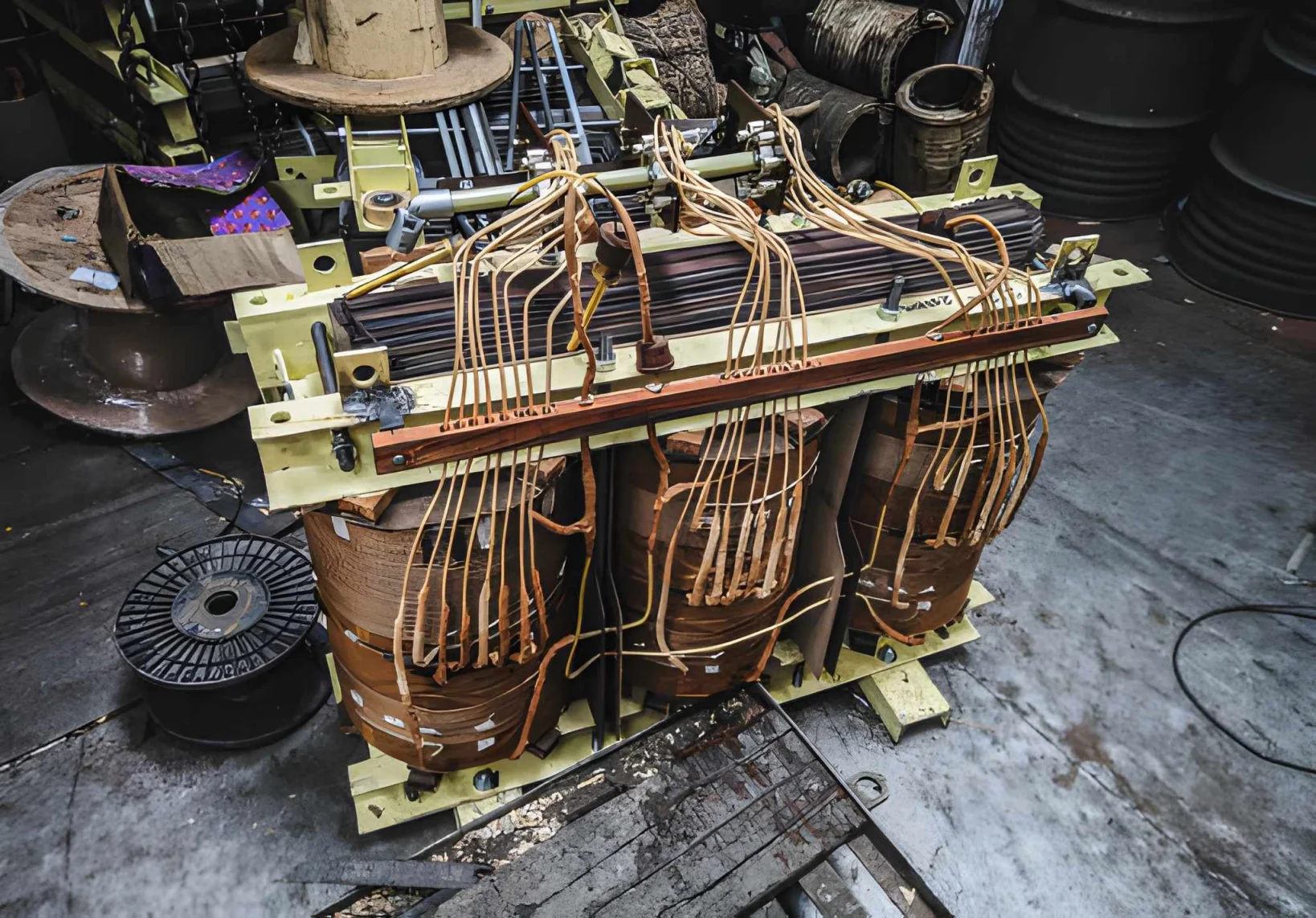

What Are Dry-Type Transformers?

A dry-type transformers is an electrical transformer that uses air instead of liquid for cooling. Unlike oil-filled transformers, their windings and core are cooled by air ventilation rather than immersed in oil. This makes them safer, more eco-friendly, and a preferred choice for indoor installations where fire risks or contamination must be minimized.

Modern dry-type transformers are used in industrial plants, commercial buildings, renewable energy systems, and data centers—essentially anywhere clean, reliable electricity is needed with minimal maintenance.

Key Advantages

- Enhanced safety: No flammable liquids mean no risk of oil leakage or fire hazards.

- Low maintenance: Fewer parts to service and no oil sampling needed.

- Environmentally sustainable: Complies with green building and safety codes.

- Quiet operation: Reduced noise levels, suitable for sensitive environments.

| Feature | Benefit | Common Applications |

|---|---|---|

| Air-cooled design | No risk of oil leakage | Indoor electrical rooms |

| VPI or cast resin insulation | Improved heat dissipation | Hospitals, malls, airports |

| Compact footprint | Easy installation and space saving | Commercial buildings |

| Low emissions | Complies with EPA and ISO standards | Eco-conscious facilities |

Types of Dry-Type Transformers

Understanding the main categories helps you match the right transformer with your operational requirements.

1. Cast Resin Transformers (CRT)

Cast resin transformers encase windings in epoxy resin to provide strong mechanical protection and excellent insulation. They resist moisture and contaminants, making them ideal for humid or coastal environments.

Best for: Wind farms, marine facilities, and manufacturing plants with harsh conditions.

2. Vacuum Pressure Impregnated (VPI) Transformers

The VPI transformer uses varnish applied under vacuum pressure. It’s durable and cost-effective for many standard applications while maintaining excellent insulation and heat performance.

Best for: Commercial facilities, schools, and data centers.

3. Open Wound Transformers

These transformers are less common but still used in controlled environments where ventilation is optimal. They are easy to inspect and repair but less tolerant to dust and humidity.

Best for: Clean industrial rooms or dedicated transformer enclosures.

| Type | Cooling Method | Typical Environment | Cost Efficiency |

|---|---|---|---|

| Cast Resin | Encapsulated epoxy | Harsh, moist, or coastal | Higher |

| VPI | Air-cooled varnish | Standard indoor | Moderate |

| Open Wound | Air ventilation | Clean, dust-free | Economical |

Key Factors When Selecting the Right Dry-Type Transformer

Selecting the right dry-type transformer is one of the most critical decisions in any commercial or industrial electrical project. A wrong specification can lead to overheating, voltage drops, early equipment failure, or even costly downtime. Below, we break down the essential factors that every procurement engineer, electrical designer, and project contractor should analyze before finalizing a transformer purchase.

1. Power Rating and Load Capacity

Power rating defines the maximum load the transformer can handle safely. It’s measured in kilovolt-amperes (kVA) and directly determines the transformer’s size and performance.

When determining the correct rating, consider both your continuous and peak load demands. For example, a data center or industrial facility with variable loads should plan for around 120–125% of the normal load to ensure flexibility and prevent overheating.

Look beyond the startup ratings—electric motors, HVAC systems, and variable frequency drives (VFD) create inrush currents that can easily exceed 7–10 times the normal load. Selecting a transformer with suitable impedance and short-circuit strength can prevent voltage dips and protect sensitive equipment.

| Load Type | Typical Demand Pattern | Recommended Safety Margin | Transformer Type |

|---|---|---|---|

| Continuous (lighting, heating) | Stable | 10% | Standard VPI type |

| Variable (motors, data servers) | Fluctuates | 20–25% | Cast resin type |

| High inrush (compressors, VFD drives) | Peaks at startup | 30%+ | Reinforced insulation design |

2. Efficiency, Energy Losses, and Heat Performance

Transformer efficiency has become a primary consideration for modern B2B buyers focusing on energy-saving equipment procurement. The higher the efficiency, the lower the energy wasted as heat—resulting in lower operational costs and reduced greenhouse gas emissions.

Losses in dry-type transformers come from two key areas:

- Core loss (no-load loss): Occurs even when the transformer is energized but not under load. Selecting a low-loss silicon steel or amorphous metal core can reduce this.

- Load loss (copper loss): Caused by current flow through windings during active load. The quality of conductor material (aluminum vs. copper) impacts this significantly.

Tip: Energy-efficient dry-type transformers that meet DOE TP1 or IEC 60076-11 Class 1 efficiency ratings often offer up to 98.5% operational efficiency. Though the upfront cost may be higher, the payback period from reduced electricity bills is often under 2 years for medium voltage installations.

| Efficiency Certification | Description | Typical Saving Potential |

|---|---|---|

| DOE 2016 Compliance | U.S. energy standard for transformers | 5–8% lower energy loss |

| EU Ecodesign Tier 2 | European standard for dry-type transformers | 6–10% more efficient |

| ISO 50001 Support | Integrated energy management compliance | Long-term cost reduction |

Ready to explore your options?

Contact us today for a custom dry-type transformers quotation — because the right transformer doesn’t just move power, it powers your entire business forward.

3. Environmental and Installation Conditions

Unlike oil-immersed transformers, dry-type transformers can be placed almost anywhere—mechanical rooms, underground substations, or rooftop enclosures. However, site conditions still matter greatly.

Key environmental factors include:

- Temperature: Dry-type transformers typically operate best below 40°C ambient temperature. In high-temperature environments, forced-air cooling (AF) can extend lifespan.

- Altitude: At elevations above 1000m, air density decreases, reducing cooling efficiency. Always derate the unit accordingly.

- Humidity and contamination: For factories, refineries, or coastal areas, a cast resin design with high IP protection (IP31–IP54) is safer against dust, salt, and moisture.

Example: A transformer installed in a coastal chemical plant should use epoxy resin encapsulation with anti-salt fog coating, while one inside an office tower may only need standard IP20 protection.

| Environment Type | Recommended Transformer | Protection Class | Notes |

|---|---|---|---|

| Indoor (data center, hospital) | VPI dry-type | IP20–IP23 | Quiet, clean operation |

| Coastal or humid region | Cast resin | IP31–IP54 | Moisture and salt resistant |

| Mining or heavy industrial plant | Reinforced class F or H | IP44+ | Handles high dust and vibration |

| Outdoor compact substation | Sealed dry-type with enclosure | IP55 | Optional AF cooling fan |

4. Insulation Class, Thermal Design, and Cooling

Insulation class determines how much temperature a transformer can handle without degrading. For high-performance industrial or renewable energy applications, Class F (155°C) or Class H (180°C) insulation is standard.

Heat management is equally decisive. Most dry-type transformers use air natural (AN) cooling for up to 85°C temperature rise, while large-capacity units adopt air forced (AF) systems with fans and temperature sensors.

Modern designs integrate thermal monitoring sensors and automatic fan control—allowing real-time adjustment based on the transformer’s load, preserving efficiency and extending lifespan.

| Insulation Class | Max Temperature (°C) | Typical Use | Cooling Type |

|---|---|---|---|

| Class B | 130 | Small buildings, schools | AN |

| Class F | 155 | Industrial facilities, malls | AN or AF |

| Class H | 180 | Heavy-duty or renewable systems | AF with sensors |

5. Safety Standards, Certifications, and Compliance

Industrial projects often require strict adherence to regional or international safety standards. Buyers should verify that their dry-type transformer supplier meets one or more of the following certifications:

- IEEE C57.12 / ANSI C84 – North American performance and safety benchmark.

- IEC 60076-11 – International standard for dry-type transformer design and testing.

- UL 1562 or CSA C9 – Safety standards for low and medium voltage applications.

- ISO 9001 / ISO 14001 – Quality and environmental management compliance.

For public infrastructure or renewable projects, consider transformers with fire-retardant materials and low-smoke, halogen-free construction. These ensure compliance with LEED, NFPA, and EcoDesign directives.

A certified transformer minimizes regulatory risk during inspection and simplifies project handover and warranty claims.

6. Noise, Vibration, and Mechanical Design

Many B2B customers overlook noise until after installation—when vibration turns into a frequent complaint. The electromagnetic flux in transformer cores generates sound and mechanical resonance, which becomes noticeable in hospitals, offices, and malls.

Opt for low-noise transformers (<60 dB) with vibration isolation pads or magnetic core clamping. Cast resin units also tend to be quieter than VPI types.

If your design includes multiple transformers in a compact room, acoustic damping panels or fan speed controls can ensure compliance with ISO 3744 noise limits.

7. Maintenance, Accessibility, and Lifecycle Cost (TCO)

The reason many engineers switch to dry-type transformers is operational convenience. No oil means no leakage checks, oil testing, or spill containment. Yet, regular inspection remains important.

Choose designs with:

- Front and rear accessibility for easy tightening of connections.

- Built-in temperature monitoring to detect abnormal heating early.

- Self-diagnostic smart sensors integrated via Modbus or Ethernet for remote monitoring.

TCO (Total Cost of Ownership) goes beyond purchase price—it considers installation, maintenance, and energy use over 20+ years. A highly efficient transformer might cost 10% more upfront but cut your lifetime energy cost by 20% or more.

| Cost Component | Standard Unit | Premium Efficiency Unit | Savings Potential |

|---|---|---|---|

| Energy cost (20 years) | $180,000 | $140,000 | $40,000 |

| Maintenance | Medium | Low | 25% reduction |

| Downtime risk | Moderate | Minimal | Extended uptime |

8. Vendor Experience and After-Sales Support

Lastly, quality is only as good as the supplier backing it. Before placing your order or sending an inquiry, check whether your manufacturer provides:

- Custom configuration for voltage ratios and enclosure type.

- Factory test reports and type testing certification.

- On-site commissioning assistance.

- Global after-sales network or warranty coverage.

A reliable dry-type transformer supplier should also be able to simulate your load conditions, issue thermal studies, and offer optimized designs for energy savings.

If you’re sourcing for an ongoing project or tenders, it’s best to contact qualified manufacturers early in your planning stage to prevent last-minute adjustments or mismatched ratings.

Common Applications of Dry-Type Transformers

Dry-type transformers are incredibly versatile. Below are some key sectors seeing rapid adoption:

- Data centers: Reliable power without the risk of oil leaks.

- Renewable energy: Integrating wind and solar systems into grids safely.

- Hospitals and universities: Safe indoor power systems with minimal maintenance.

- High-rise buildings and airports: Compact design, quieter performance.

- Shopping malls and hotels: Compact installation, low noise operation.

- Manufacturing facilities: Handles variable load profiles safely.

- Wind and solar farms: Excellent for renewable applications.

- High-rise and underground substations: Oil-free means safer urban integration.

If your project falls in one of these categories, now is a great time to contact a supplier for tailored consultation or RFQ submission. Custom-engineered designs can be configured to meet very specific load and space constraints.

Selecting the right dry-type transformer isn’t just about capacity—it’s about balancing performance, safety, and sustainability. By understanding your environment, load demands, and compliance needs, you can ensure your investment supports stable, energy-efficient operations for decades.

Whether you’re planning a retrofit, expanding an industrial network, or building a new facility, choosing the right partner can make all the difference. Looking for expert guidance or a quote? Contact our team today to explore high-performance dry-type transformer solutions tailored to your project requirements.

FAQ

Are dry-type transformers more expensive than oil-filled ones?

Generally, yes—initial costs are higher, but they save money on installation and maintenance, especially in indoor or urban projects.

Can dry-type transformers be installed outdoors?

Yes, if they are properly enclosed and rated (IP33 or above) to handle moisture and dust.

What is the typical lifespan of a dry-type transformer?

With regular inspection and proper ventilation, most units last 25–35 years.

Do dry-type transformers require cooling fans?

Some higher-capacity models use forced air cooling (AF) to enhance performance under heavy loads.

How do you order the right transformer size?

Send your electrical specifications—voltage, capacity, frequency, and environment—to your supplier. Most manufacturers provide a custom specification service or engineering assistance for project-based selection.

Table of Contents

Ready to explore your options?

Contact us today for a custom dry-type transformers quotation — because the right transformer doesn’t just move power, it powers your entire business forward.