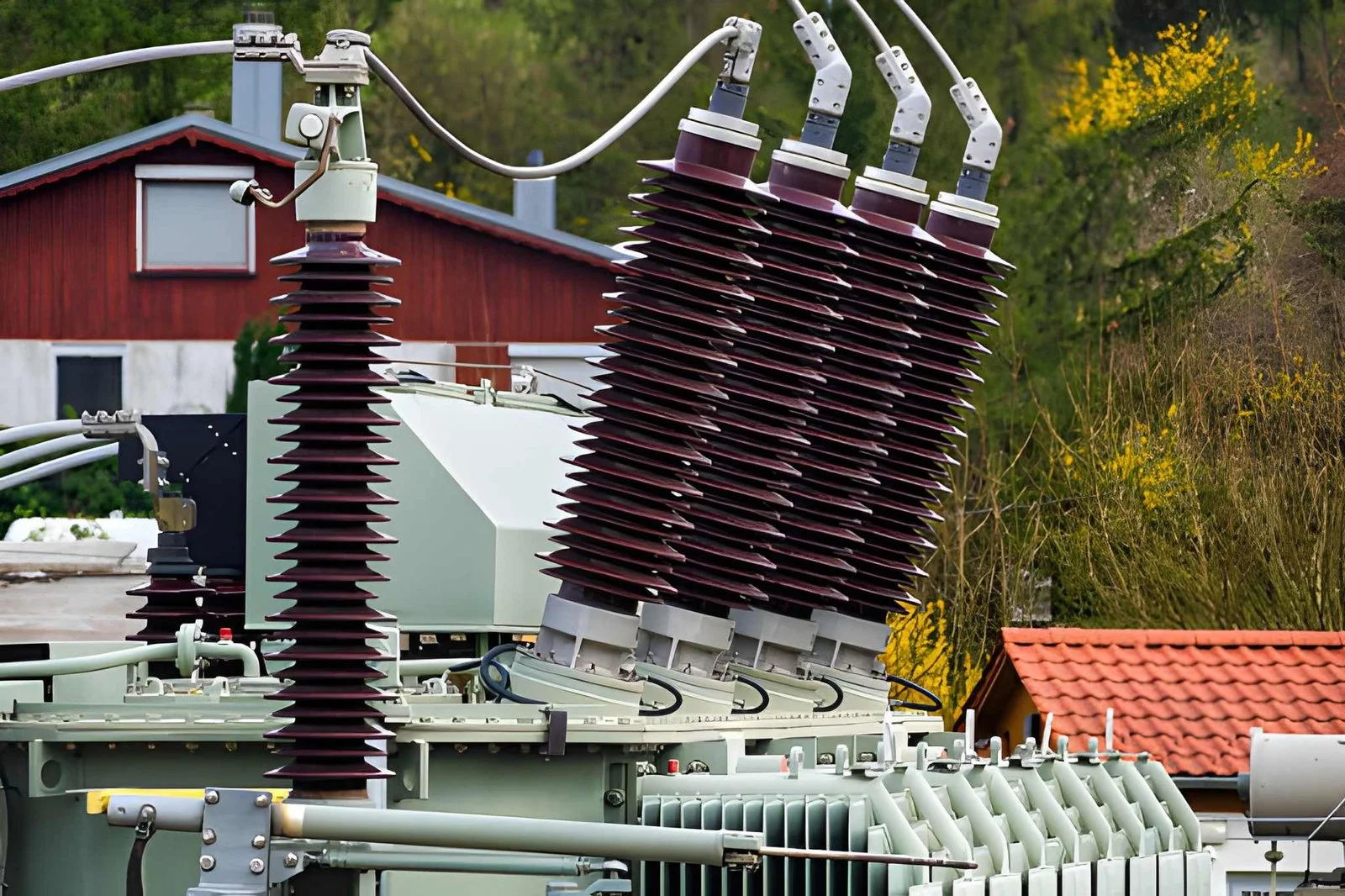

When a Dry-Type Transformer is running in your plant room or substation, it looks like a silent metal box. But inside, there is a precise electromagnetic machine converting voltage levels safely and efficiently, without a drop of oil.

This article breaks down how a Dry-Type Transformers works step by step, in language that makes sense for project engineers, consultants, and procurement teams. Along the way, long-tail terms like cast resin dry-type transformer, VPI transformer, dry-type distribution transformer, and indoor dry-type power transformer will be used naturally, so you can also use this as a buying guide. If you need technical support or a fast quotation while reading, feel free to send an inquiry based on your project data sheet anytime.

What Is Happening Inside a Dry-Type Transformer?

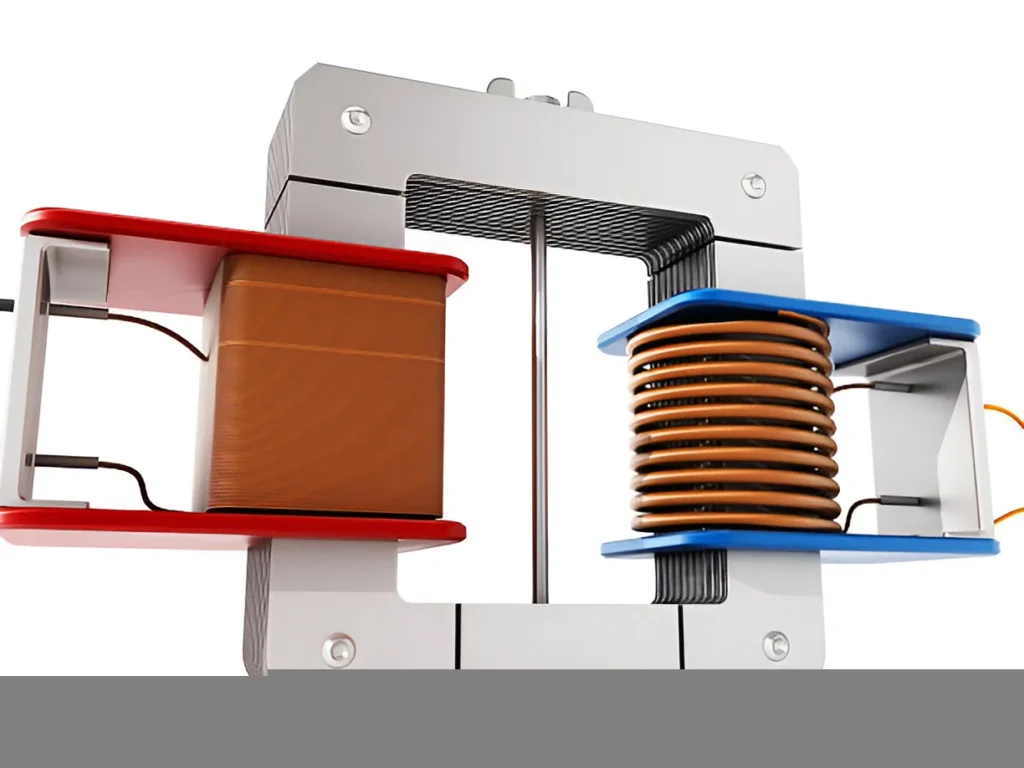

At its core, a dry-type transformer uses electromagnetic induction to transfer power between circuits with different voltages, using air and solid insulation instead of oil. The magnetic core, primary winding, and secondary winding work together to step voltage up or down while keeping electrical isolation between input and output.

In a typical low-voltage or medium-voltage dry-type distribution transformer, multiple secondary windings may be used, allowing one transformer to feed several loads at different voltage levels. The whole active part is placed in an enclosure where cooling air can flow around the coils and core to remove heat.

If your project specification emphasizes fire safety, low maintenance, and indoor installation, this internal structure is exactly why a dry-type transformer is typically recommended over an oil-immersed unit for schools, hospitals, commercial buildings, and industrial facilities.

Step-by-Step Working Principle of a Dry-Type Transformer

So, how does a dry-type transformer work from the moment you energize the primary side until the power reaches your load?

1. Electromagnetic Induction Takes Over

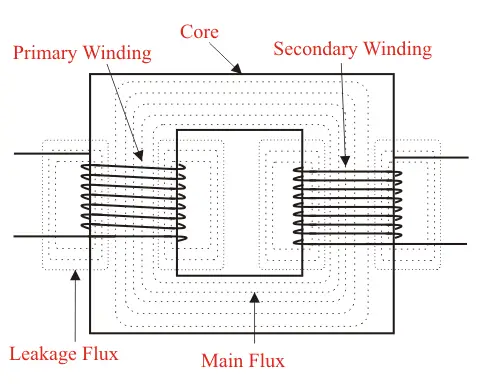

When alternating current flows into the primary winding, it produces an alternating magnetic field in the laminated steel core. The changing flux links with the secondary winding, and by the principle of electromagnetic induction, a voltage is induced on the secondary side.

The relationship between the primary and secondary voltage is determined by the turns ratio – more turns on the secondary side means step-up, fewer turns means step-down. In real-world dry-type power transformers, the design also needs to consider leakage reactance and impedance to ensure stable fault performance under short-circuit conditions.

2. Power Transfer and Voltage Transformation

In an ideal situation, the input power equals the output power (minus small losses), so if voltage is stepped down, current increases proportionally to keep power balanced. For example, stepping from 10 kV to 0.4 kV for a plant’s low-voltage switchboard increases current significantly, so copper cross-section, thermal design, and insulation class become critical.

This efficient energy transfer is why dry-type transformers are widely used in distribution networks, industrial switchgear rooms, and renewable energy inverters, especially where environmental safety is a priority.

3. Cooling: Air, Not Oil

The main difference between dry-type and oil-immersed transformers is the cooling method. Instead of circulating mineral oil, dry-type transformers rely on air – either natural convection (AN/AA) or forced air with fans (AF).

As the transformer operates, heat generated by copper losses and core losses warms the surrounding air, which rises and exits through ventilation openings while cooler air enters from below. In larger dry-type power transformers, additional fans or air blast systems can be added to increase loading capability and reduce temperature rise.

If you are sizing a dry-type transformer for a plant upgrade, always verify cooling class, temperature rise, and ambient conditions, because they directly control how much continuous load the transformer can safely carry.

Key Components and Construction of Dry-Type Transformer

Understanding how each component is built helps you better evaluate different dry-type transformer manufacturers, whether you are comparing a cast resin dry-type transformer to a VPI transformer or checking quotations for an indoor dry-type distribution transformer.

Magnetic Core

The core is usually made from laminated electrical steel, stacked to reduce eddy current losses while guiding magnetic flux between the windings. High-grade core materials and optimized geometry reduce no-load losses, which can significantly improve energy efficiency over the transformer’s lifetime.

Windings

Primary and secondary windings are made from copper or aluminum conductors, insulated and arranged to manage voltage stress and mechanical forces during fault conditions. Modern dry-type transformers often use layer or disc windings to balance electrical, thermal, and mechanical performance for medium-voltage grids and industrial applications.

Insulation and Encapsulation

The defining feature of a dry-type transformer is the insulation system: solid materials instead of liquid. Common systems include polyester varnish, epoxy resin, or other high-performance polymers that protect windings against moisture, dust, and contaminants. High-quality insulation enhances dielectric strength and helps transfer heat out of the coils.

There are three main insulation system styles widely used in the market.

If your project is in a coastal area, tunnel, chemical plant, or high-moisture environment, choosing a cast resin dry-type transformer or an epoxy-encapsulated design will usually provide better long-term reliability than a basic varnish system.

Cooling Methods and Temperature Rise in Dry-Type Transformers

Heat is the enemy of insulation. So, in any dry-type transformer design, cooling class and temperature rise are not just technical details; they are directly linked to lifetime and reliability.

Natural Air Cooling (AN/AA)

In small to medium kVA ratings, many dry-type transformers use natural air cooling, where heat naturally rises, drawing cool ambient air through the vents. This method has no moving parts, so it is silent and requires minimal maintenance, but it offers limited overload capacity.

Forced Air Cooling (AF) and Air Blast

For larger dry-type power transformers, forced air cooling is added by mounting fans that blow air over coils and core, increasing heat transfer. In very high power or demanding environments, air blast cooling uses high-velocity air streams for rapid heat removal under heavy loads.

When you evaluate offers, always check the specified temperature rise (for example 80 K or 115 K) and insulation class, because a lower temperature rise dry-type transformer will usually deliver a longer service life and better overload margin. This also matters for energy-intensive facilities, where downtime is extremely costly.

Common Dry-Type Transformer Types and Applications

From an engineering and purchasing perspective, not all dry-type transformers are equal. Different constructions target different environments and applications.

Main Types of Dry-Type Transformers

Dry-type transformers are commonly categorized as cast resin, VPI, or VPE/epoxy encapsulated, all using air as the primary cooling medium. They share the same electromagnetic working principle, but their insulation systems and mechanical robustness differ.

Typical Applications

Because there is no flammable oil, dry-type power transformers are preferred in places with strict fire safety and environmental regulations, such as high-rise buildings, hospitals, data centers, universities, metro stations, and manufacturing clean rooms. They are also widely used in wind and solar projects as dry-type distribution transformers, especially when mounted indoors or in compact substations.

If you are planning a new project or retrofit, sharing your load data, ambient conditions, and installation environment with a professional dry-type transformer supplier is the fastest way to get a technically correct and cost-effective proposal tailored to your use case.

FAQ

Does a dry-type transformer work differently from an oil-immersed transformer?

The basic working principle is the same: both use electromagnetic induction to transfer energy between primary and secondary windings on a magnetic core. The key difference is the cooling and insulation system – dry-type transformers use air and solid insulation instead of oil, which improves fire safety and environmental performance in many indoor applications.

Why do dry-type transformers run hotter than oil-filled units?

Dry-type transformers rely on air cooling, which has a lower heat capacity than mineral oil, so for the same kVA rating and loading, their operating temperatures can be higher. That is why proper ventilation, cooling class selection, and, when necessary, forced air fans are critical in the design and installation of dry-type power transformers.

Can a dry-type transformer be installed outdoors?

Yes, but it requires the right enclosure (such as NEMA 3 or equivalent) and an insulation system suitable for moisture and environmental exposure, such as cast resin or epoxy-encapsulated designs. Many manufacturers offer outdoor-rated dry-type distribution transformers specifically for moderate climates and protected outdoor substations

Are dry-type transformers suitable for high power or only for small loads?

Modern dry-type technology supports medium and even high power ratings, and with forced air cooling or air blast techniques, they can handle significant continuous loads and reasonable overloads. However, for very large grid-scale power transformers, oil-immersed designs may still be more common due to their cooling and cost structure.

How do I choose between cast resin and VPI dry-type transformers?

Cast resin dry-type transformers offer superior moisture resistance and mechanical robustness, ideal for harsh or high-humidity environments and high fire safety zones. VPI transformers are typically more cost-effective and are well suited to standard industrial plants and commercial installations where environmental conditions are moderate.

Table of Contents

Ready to explore your options?

Contact us today for a custom Dry-Type Transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.