When you compare a Dry Type Transformer with a cast resin transformer, you are not looking at two completely separate products but at a broad category versus one specific technology inside that category. A dry type transformer is any transformer that uses air instead of oil for cooling, while a cast resin transformer is one particular dry type design in which the windings are fully encapsulated in epoxy resin.

For purchasing managers, EPC contractors, and design engineers, understanding this relationship is critical to avoid confusion in specifications, RFQs, and technical evaluations. The right choice will affect fire safety, maintenance cost, total cost of ownership, and reliability in demanding environments such as industrial plants, data centers, and metro projects.

What Is a Dry Type Transformer?

A dry-type transformers is a transformer that uses solid insulation and air (natural or forced) for cooling instead of mineral oil or synthetic liquid. This makes it especially attractive for indoor power distribution, commercial buildings, and applications where fire and environmental risk must be minimized.

From a technology point of view, most industrial dry type transformers today fall into three main sub‑types: cast resin, VPI (Vacuum Pressure Impregnated), and VPE (Vacuum Pressure Encapsulated). When you see “dry type transformer” in tenders or data sheets, it usually refers to one of these insulation systems.

Typical dry type transformer characteristics

In many international projects, the dry type transformer is preferred over oil‑immersed units where people are working close to the equipment or where additional oil catch pits and fire walls would increase civil cost. For a procurement team, this often translates into shorter approval cycles with safety departments and easier permitting from local authorities.

What Is a Cast Resin Transformer?

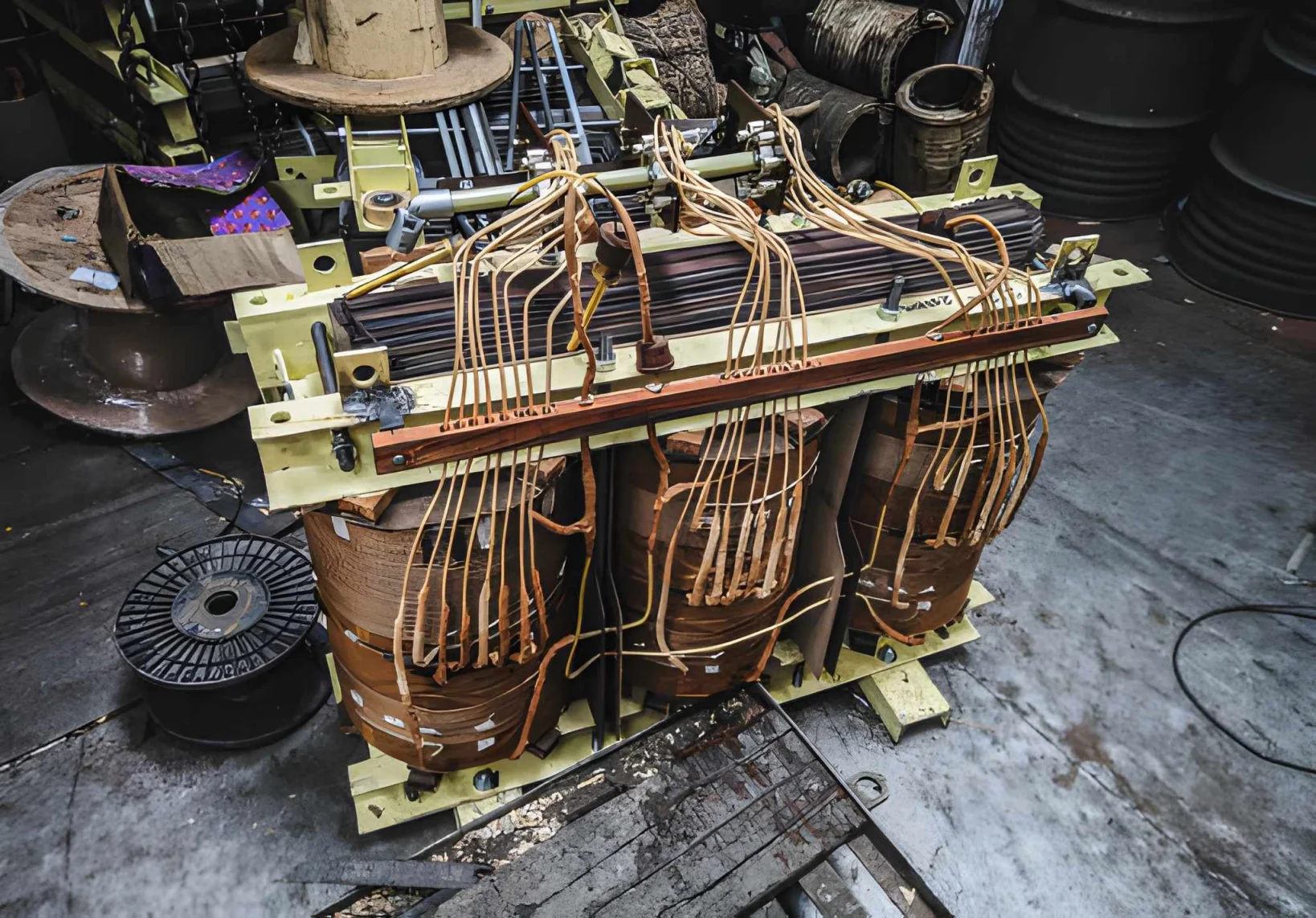

A cast resin transformer (often called cast resin dry type transformer or epoxy cast dry type transformer) is a specific variant of dry type transformer where the windings are completely embedded in epoxy resin under vacuum. The solid cast insulation provides high mechanical strength, excellent dielectric performance, and strong resistance to moisture and pollution.

In cast resin designs, the low‑voltage windings are usually made of foil or wire and poured into epoxy resin molds, while the medium‑voltage windings are also resin‑encapsulated to form a rigid block. The result is a transformer that tolerates harsh environments such as coastal regions, tunnels, offshore platforms, and industrial plants with dust or chemical contamination.

Key cast resin transformer features

From a B2B perspective, “cast resin dry type transformer 11kV”, “SCB cast resin transformer supplier”, or “indoor cast resin transformer for data center” are typical long‑tail phrases used by engineers and buyers when shortlisting vendors. Including these terms naturally in technical documentation, datasheets, and blog content can help your product pages reach the right professional audience.

Dry-Type Transformer vs Cast Resin What Is the Real Difference

Here comes the part that often causes confusion in RFQs and tender documents. A dry-type transformers is a broad category that includes several technologies, while a cast resin transformers is one specific technology inside this group. Strictly speaking, all cast resin transformers are dry type transformers, but not all dry type transformers are cast resin.

Other dry type technologies, such as VPI and VPE, use vacuum processes to impregnate the windings with resin and varnish instead of forming a fully solid block. These designs still provide good insulation and reasonable moisture resistance, but with different performance, cost, and application profiles compared with cast resin.

Technology comparison: dry type vs cast resin

So if a specification says “dry-type transformer, VPI technology”, cast resin transformers are not mandatory; another dry type technology is allowed as long as it meets performance requirements. If it says “cast resin dry type transformer”, only epoxy cast designs will pass the technical compliance check.

For buyers, taking time to clarify this difference during pre‑bid meetings can avoid repeated technical queries, re‑submittals, and costly redesigns later. When in doubt, ask your transformer supplier to provide two options in the quotation: one for general dry type (for example VPI) and one for cast resin, with clear cost and performance comparison.

Ready to explore your options?

Contact us today for a custom Dry Type Transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.

The most suitable application scenarios for each type

From a project engineering perspective, the “best” transformer is the one that fits your environment, safety requirements, and budget. Different dry-type designs perform differently in damp basements, dusty factories, or clean server rooms. That is why application‑driven selection is more important than simply choosing the latest technology.

Cast resin dry-type transformers shine in harsh or demanding environments. Their resin‑encapsulated windings are protected against condensation, salt fog, and chemical contaminants, so they are often used in metros, tunnels, offshore platforms, wind farms, and heavy industrial plants. VPI or VPE dry type transformers, on the other hand, are a strong choice for standard indoor installations where the environment is reasonably clean and humidity is controlled, such as commercial buildings, schools, and office complexes.

Typical application mapping

If your team is currently sizing a transformer for a new substation or retrofit, this is a good stage to engage with manufacturers and share your single‑line diagrams, loading profile, and environmental data. Many suppliers now offer online “dry-type transformer sizing tools” or quick‑selection guides tailored to B2B engineering teams. A short technical consultation at this stage can prevent under‑specification (leading to overheating) or over‑specification (unnecessary cost and footprint).

Cost, Maintenance, and Total Ownership

From a purely purchase‑price perspective, a VPI dry type transformer is typically cheaper than a cast resin unit with similar rating and voltage. However, procurement decisions today rarely focus only on the first invoice; engineering and sourcing teams look at total cost of ownership over 20–30 years of operation.

Dry type transformers in general do not require oil sampling, oil replacement, or leak monitoring, which reduces routine maintenance and HSE management effort compared with oil‑filled transformers. Within the dry type family, cast resin units usually offer the lowest maintenance burden because the rigid insulation system is highly resistant to moisture ingress and mechanical damage.

Cost and maintenance overview

For B2B buyers managing a portfolio of facilities, this balance is important. A slightly higher CAPEX for cast resin transformers can be justified by lower OPEX in coastal plants, port terminals, or chemical facilities where standard dry type units may suffer from corrosion or partial discharge over time. On the other hand, in a clean office complex or logistics warehouse, a general dry type transformer can deliver excellent performance at a more competitive upfront price.

If you want a specific TCO comparison for your project, feel free to share your rating, expected load factor, and environment class—suppliers can usually prepare an energy‑loss and maintenance cost calculation as part of the quotation.

How to Specify the Right Transformer in RFQ

Many RFQs simply say “dry type transformer, 1600 kVA, 10/0.4 kV”, which leaves a lot of room for interpretation. For complex projects, this can lead to a mix of technologies in vendor offers, making technical comparison more complicated and slowing down the evaluation process. Clear technical specification helps both sides: the buyer gets more comparable offers, and the manufacturer can design exactly what the project needs.

At a minimum, RFQs for dry type transformers should define rating, primary and secondary voltage, impedance, insulation level, installation environment, cooling method, and any specific standards (such as IEC or ANSI). If the project requires a cast resin dry type transformer, this should be stated clearly together with any special fire‑performance or low‑smoke requirements from local codes or the end‑user.

Helpful items to include in an RFQ

When your RFQ is ready, you can send it simultaneously to several dry type transformer manufacturers or OEM partners to compare technology options and commercial terms. If you are working on a fast‑track project and want a quick budgetary quote, most suppliers can propose standard dry type transformer configurations based on a one‑line description and a rough duty cycle.

If you are comparing dry type transformer and cast resin options for an upcoming project and need a clear technical‑commercial proposal, share your basic specs and environment requirements so a tailored recommendation and quotation‑ready specification can be prepared.

FAQ

Is a cast resin transformer the same as a dry type transformer?

No. A cast resin transformer is a type of dry type transformer, but dry type also includes technologies like VPI and VPE.

When should an engineer choose a cast resin dry type transformer?

Cast resin dry type transformers are recommended for humid, coastal, dusty, or chemically aggressive environments, and for projects with very strict fire‑safety requirements.

Are dry type transformers more expensive than oil‑filled transformers?

The initial purchase price can be higher than some oil‑filled designs, but dry type transformers reduce costs for fire‑protection systems, oil handling, and environmental measures, which can improve lifecycle economics.

Do dry type transformers need special maintenance?

They need regular visual inspection, cleaning, and basic electrical testing, but they do not require oil sampling or leak management, which simplifies maintenance programs.

How can a buyer improve SEO visibility for dry type transformer products?

Using natural long‑tail phrases such as “dry type transformer for industrial plant”, “cast resin dry type transformer 10kV”, or “low‑voltage dry type transformer supplier” in product pages and blogs helps reach professional search intent in 2025.