Keeping a dry type transformer in optimal condition is not just about extending its lifespan—it’s about ensuring your operation runs without unexpected downtime. Whether you’re overseeing a manufacturing facility, data center, or commercial building, transformer maintenance plays a critical role in energy efficiency and reliability.

Let’s break down how to maintain a dry type transformer effectively, what warning signs to look for, and how proactive maintenance can protect your investment.

Understanding Dry Type Transformers

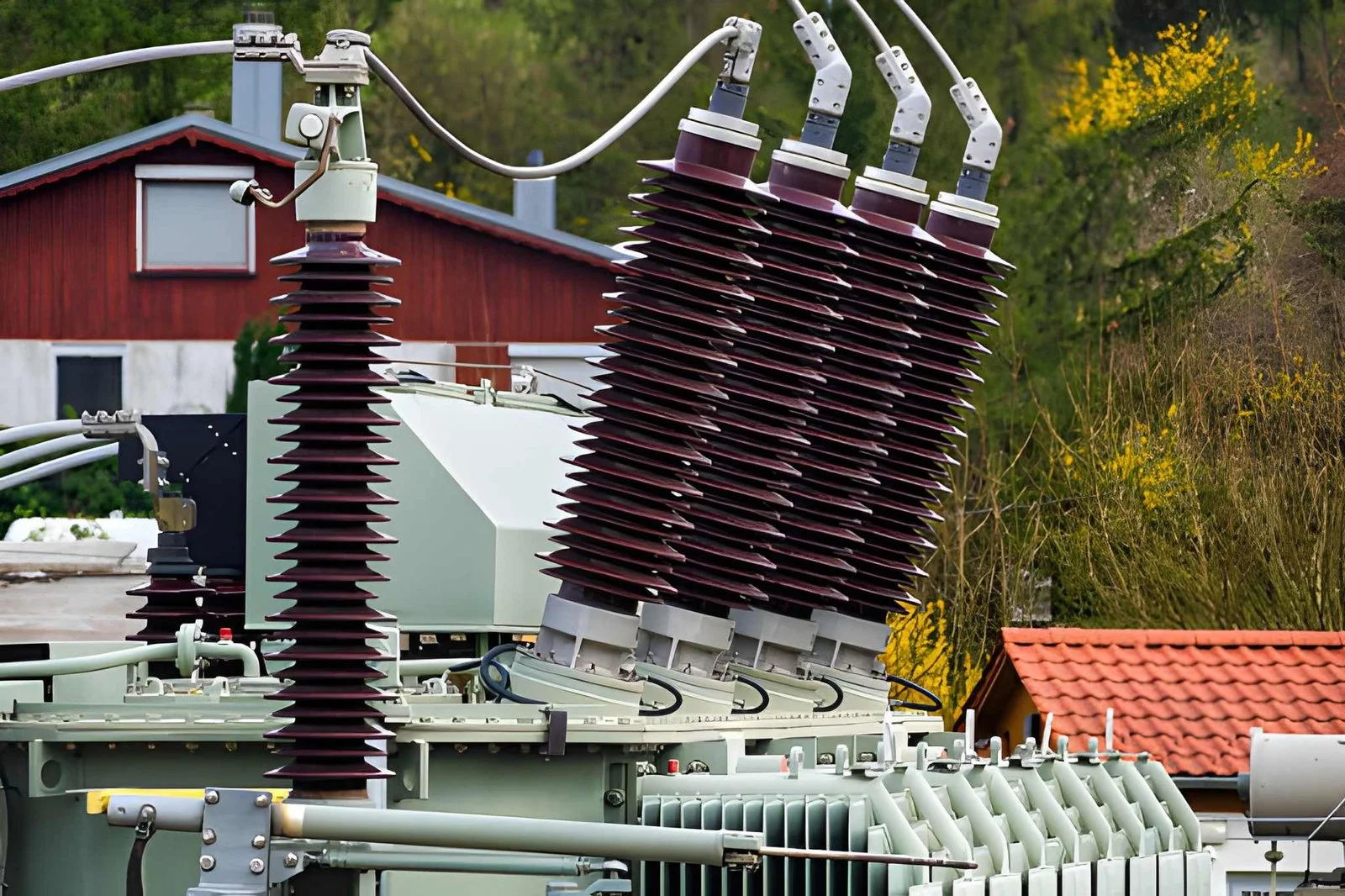

A dry type transformer operates without any liquid insulation; instead, it relies on air for cooling. This makes it a safer, eco-friendlier choice—especially for indoor installations where oil leaks or fire hazards could be catastrophic.

There are two main types:

- Cast resin dry type transformers (CRT): Known for excellent moisture resistance and performance in humid or dusty environments.

- Vacuum pressure impregnated (VPI) transformers: Provide reliable mechanical strength and are ideal for commercial and light industrial applications.

| Type | Cooling Method | Best Application | Key Benefit |

|---|---|---|---|

| Cast Resin (CRT) | Air Natural (AN) | Humid or polluted areas | Moisture & dust resistance |

| Vacuum Pressure Impregnated (VPI) | Air Forced (AF) | Indoor commercial sites | Mechanical durability |

Understanding your transformer type determines the right maintenance plan, inspection schedule, and cleaning approach.

Why Maintenance Matters

A well-maintained transformer directly impacts:

- Operational reliability: Regular inspections prevent sudden failures.

- Safety compliance: Reduces risks associated with overheating or insulation degradation.

- Energy efficiency: Clean coils and balanced loads result in lower energy losses.

- Reduced downtime: Scheduled servicing minimizes costly unplanned outages.

Think of it like caring for an engine—maintenance isn’t optional, it’s essential.

Routine Visual Inspection

Visual checks are the first line of defense. Schedule them at least once every 3 to 6 months.

Look for:

- Dust or debris buildup: Air-cooled transformers need proper airflow to dissipate heat effectively.

- Corrosion or discoloration: Indicates overheating or high humidity exposure.

- Loose connections or joints: Can cause partial discharges and potential electrical faults.

- Noise or vibration: Unusual humming or vibration could mean a mechanical or electrical imbalance.

When issues surface, document them immediately and address small faults before they evolve into major breakdowns. A quick response could save thousands in repair costs.

Cleaning and Airflow Management

Dust and moisture are the two biggest enemies of a dry type transformer. Excessive contamination leads to hot spots and partial discharge within the windings.

Here’s what to do:

- Shut down power and ensure safety grounding.

- Use dry compressed air or vacuum cleaners (never wet cloths) to remove dust.

- Inspect ventilation pathways: Fans, ducts, or filters should be clear of obstructions.

- Monitor ambient temperature: Ensure it aligns with the transformer’s rated performance window.

In environments like cement plants, mining facilities, or paper mills, cleaning frequency should increase due to high airborne contaminants.

| Environment | Recommended Cleaning Frequency | Precaution |

|---|---|---|

| Clean indoor (office, data center) | Every 12 months | Basic dust removal |

| Industrial (manufacturing, plant) | Every 3-6 months | Use vacuum — avoid moisture |

| Coastal or humid areas | Quarterly | Inspect insulation regularly |

Thermal and Load Monitoring

Thermal management is critical because heat is the biggest factor affecting insulation life.

Continuous temperature monitoring can help:

- Identify overloading or imbalanced loads

- Prevent overheating of windings

- Maintain optimal operating temperature, usually under 150°C (class F insulation)

Load recordings also ensure balanced phase distribution. Unbalanced phases generate excessive heat in one section, accelerating insulation degradation.

Installing temperature sensors or IoT-based monitoring systems allows you to track performance remotely—a valuable feature for facility engineers managing multiple substations.

Ready to explore your options?

Contact us today for a custom Dry Type Transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.

Electrical Testing and Insulation Health

Periodic electrical tests verify your transformer’s internal integrity.

Key tests include:

- Insulation resistance (IR) test: Measures the dielectric strength of the insulation system.

- Turns ratio test: Ensures voltage ratio accuracy between windings.

- Winding resistance test: Detects loose connections or internal winding issues.

- Partial discharge test (PD): Evaluates any partial electrical discharges within insulation.

For high-capacity units (500 kVA and above), annual testing is advisable. Use certified service technicians or a qualified transformer maintenance partner.

| Test Type | Frequency | Purpose |

|---|---|---|

| Insulation Resistance | Annual | Check insulation condition |

| Turns Ratio | Every 2 years | Verify winding accuracy |

| Partial Discharge | On-demand or 2 years | Detect insulation defects |

| Thermographic Scan | Bi-annual | Identify hot spots |

Moisture and Contamination Control

Though dry type transformers handle moisture better than oil-filled ones, high humidity still reduces insulation properties.

Tips:

- Keep the installation room below 80% relative humidity.

- Use space heaters or dehumidifiers in damp environments.

- Avoid direct water exposure during cleaning or construction.

- For cast resin types, check surface resistivity periodically to assess insulation performance.

Cooling System Inspection

If your dry type transformer includes forced air cooling (AF) fans, keep them clean and operational.

Inspect:

- Fan blades and filters for dust or obstruction.

- Temperature sensors and thermostats for calibration accuracy.

- Control relays to ensure automatic cut-in at preset temperature values.

A reliable cooling system extends transformer life by maintaining consistent thermal balance.

Updating and Retrofitting Older Units

Transformers aged 10+ years may benefit from upgrades like:

- New protective relays

- Smart load monitoring

- Improved insulation materials

- Harmonic filters or surge arresters

Such upgrades don’t just enhance performance—they also bring older transformers up to modern IEEE and IEC standards, ensuring energy efficiency and compliance for industrial buyers.

Common Mistakes to Avoid

- Ignoring minor warning signs. Even small noises or minor heating should not be dismissed.

- Overloading the transformer. Always maintain loads within rated capacity.

- Skipping documentation. Maintenance logs help analyze long-term performance.

- Neglecting ventilation systems. Poor airflow accelerates deterioration.

- Mixing parts from different specifications. Always follow OEM-recommended spares.

Regular attention to these details makes a big difference in reliability and operational safety.

When to Call a Professional

While in-house engineers can handle basic inspections, complex tests—especially high-voltage testing—should be done by professionals.

If you notice unusual noise, persistent hot spots, or insulation odor, schedule a diagnostic service right away. Don’t wait for failure; preventive service is far cheaper than emergency replacements.

Maintaining a dry type transformer isn’t complicated, but it demands consistency. Regular inspections, cleaning, testing, and documentation ensure reliable performance and peace of mind.

By prioritizing preventive maintenance, you maximize uptime, maintain energy efficiency, and avoid expensive breakdowns.

If your facility relies on critical power equipment, reach out to a trusted transformer manufacturer or service provider to schedule your next maintenance assessment or get support for upgrading your current transformer system.

FAQ

How often should I clean a dry type transformer?

Every 6–12 months depending on environmental conditions.

Can I use water to clean the transformer?

No. Always use dry cleaning methods such as vacuuming or compressed air.

What causes overheating in dry type transformers?

Overloading, blocked ventilation, or poor connections.

How long does a dry type transformer last?

Typically 20–30 years with proper maintenance.

What is the key advantage over oil-filled types?

Higher safety in indoor use, no oil leaks, and lower fire risk.

Where can I buy quality dry type transformers or maintenance parts?

Contact your local certified manufacturer or send us your inquiry—we offer customized dry type transformer solutions for industrial and commercial operations worldwide.

Table of Contents

Ready to explore your options?

Contact us today for a custom Dry Type Transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.