Modern industries run on power — and the backbone of reliable power distribution often lies in one crucial component: the dry type transformer. Whether you’re an electrical engineer designing a data center or a procurement specialist sourcing components for a manufacturing facility, finding the right dry type transformer supplier can significantly impact performance, safety, and long-term ROI.

Let’s break down what to look for, why it matters, and how the right partner can help you power your project with confidence.

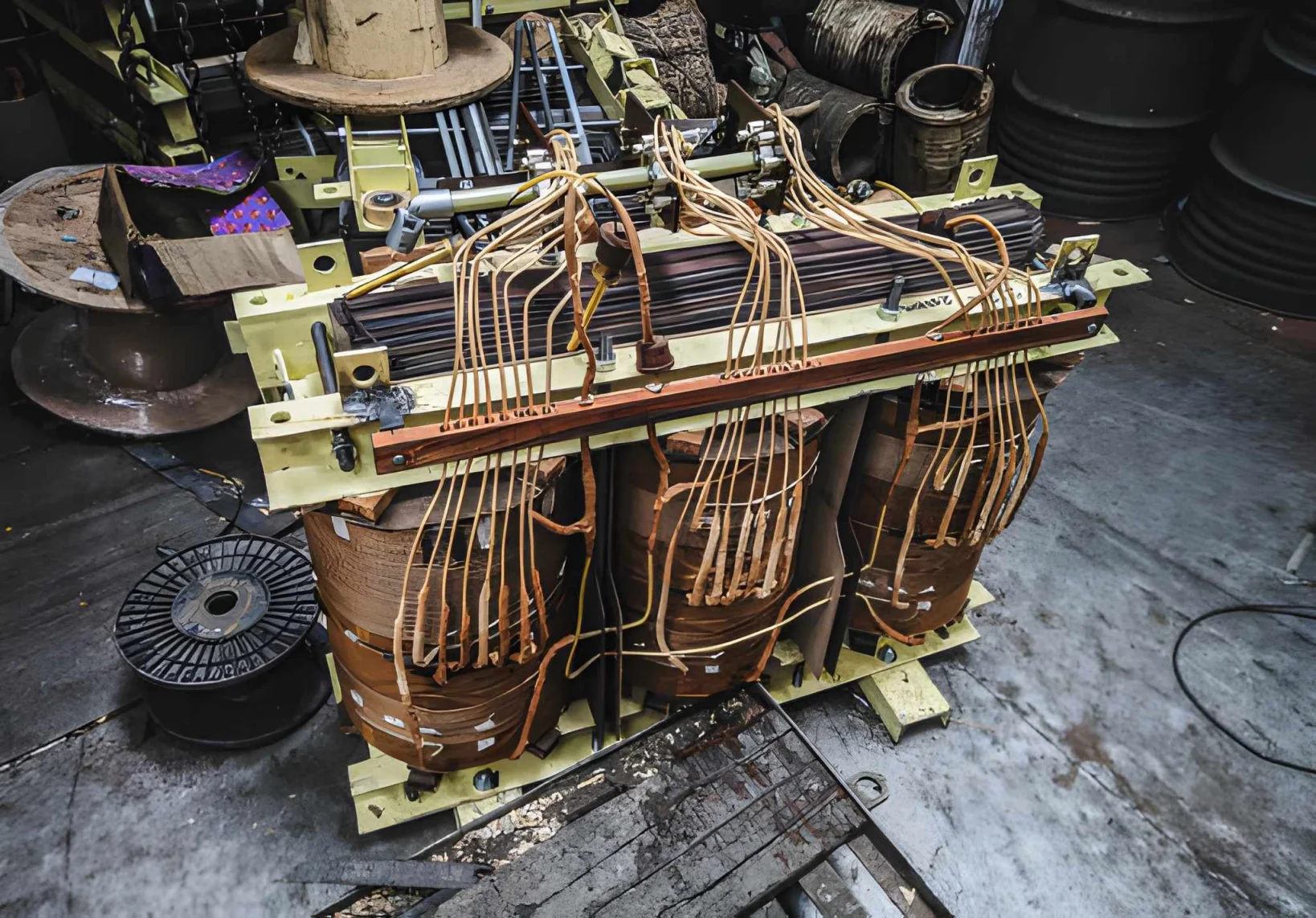

Understanding Dry Type Transformers

A dry type transformer is an electrical transformer that uses air instead of liquid oil for cooling and insulation. Inside, the windings and core are protected by epoxy or cast resin. Because no oil is involved, these transformers are environmentally friendly, low-maintenance, and safe for indoor installations.

They’re commonly used in:

- Commercial buildings

- Industrial plants

- Renewable energy systems

- Data centers

- Marine and underground applications

Dry type transformers are also ideal for sites where fire safety and environmental standards are strict—such as hospitals, schools, and public facilities.

Why B2B Buyers Prefer Dry Type Transformers

For business and industrial applications, the choice isn’t just about convenience—it’s about compliance, cost, and reliability. Here’s why procurement and engineering teams often choose dry type power transformers:

- Enhanced safety. With no oil, the risk of fire and leakage is practically eliminated.

- Ease of maintenance. Since there’s no cooling oil, operators skip regular fluid tests and oil changes.

- Compact and versatile design. These transformers fit easily into compact indoor substations.

- Environmental sustainability. No harmful chemicals or spills into the soil or water.

Now that the advantages are clear, let’s talk about what makes a supplier truly stand out.

What to Look For in a Dry Type Transformer Supplier

When sourcing a dry type transformer manufacturer or supplier, the partnership is just as important as the product. Consider the following key factors:

| Evaluation Criteria | Description | Why It Matters |

|---|---|---|

| Technical Expertise | Experience in designing transformers that meet IEC, IEEE, or ANSI standards. | Ensures compliance and reliability. |

| Customization Capability | Ability to deliver tailored voltages, frequencies, and kVA ratings. | Optimizes transformer performance for unique applications. |

| Certifications | ISO 9001, CE, UL, or IEC certifications. | Indicates consistent quality and adherence to global standards. |

| After-Sales Support | Testing, maintenance, and rapid response service. | Reduces downtime and repair costs. |

| Delivery Capability | Reliable production timelines and logistics. | Keeps project schedules on track. |

A supplier that checks all these boxes doesn’t just sell — they solve problems. That’s the kind of partner engineering teams need.

Customization: The Signature of a Professional Supplier

Not all dry type transformer suppliers offer the same flexibility. Mid-sized and large industrial clients often require custom dry type transformers with specific voltage ratios, enclosure types, or cooling methods (like AN, AF, or ANAF systems).

For example:

- Data centers may need low-voltage cast resin transformers with enhanced temperature monitoring.

- Marine applications often require corrosion-resistant housings and vibration-resistant mounting.

- Mining or heavy industry may demand reinforced insulation against dust and high temperatures.

A custom dry type transformer manufacturer will usually start by analyzing your load requirements, harmonic distortion levels, and environmental conditions before proposing an optimized design. That level of precision can mean major energy savings and performance stability over time.

Comparing Dry and Oil-Filled Transformers

It’s worth revisiting an often-debated question: Should you choose a dry type or oil-filled transformer?

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Medium | Air or cast resin | Mineral or silicone oil |

| Fire Risk | Very low | Moderate to high |

| Maintenance | Minimal | Requires regular oil checks |

| Installation | Ideal for indoor use | Mostly outdoor |

| Environmental Safety | Excellent | Needs spill control measures |

| Initial Cost | Slightly higher | Lower initial cost |

| Lifecycle Cost | Lower | Higher due to maintenance |

For most commercial and industrial buyers, dry type units are worth the slightly higher upfront cost because they reduce long-term maintenance and safety liabilities.

How Suppliers Ensure Transformer Quality

Quality assurance is a non-negotiable element when choosing a power transformer supplier. The best manufacturers use strict testing procedures, including:

- Impulse and high-voltage tests to verify insulation integrity

- Temperature rise tests to confirm cooling performance

- Partial discharge tests to ensure minimal losses and noise

- Routine factory acceptance tests (FATs) before shipment

Many suppliers now offer digital documentation or remote monitoring options to track transformer performance post-installation — a major advantage for facility managers seeking transparency.

Global Standards and Local Compliance

A reputable industrial transformer supplier designs its products to meet both global and local regulatory standards. For instance:

- IEC 60076 – for distribution and power transformers

- ANSI C57 – for North American compliance

- ISO 9001:2015 – for quality management systems

Buyers in regions with specific grid requirements (like the U.S., Europe, or the Middle East) must ensure the supplier’s transformers can adapt to local voltage specifications.

Lead Time and Supply Chain Management

In large-scale electrical projects, timing can make or break success. Choosing a dry type transformer supplier with a robust supply chain can prevent costly delays. Here’s what procurement engineers should confirm upfront:

- Average lead times for standard vs. custom units

- Material sourcing transparency (especially copper, steel, and resin)

- Shipping and export support, including documentation and packaging standards

Many international suppliers keep local distributors or warehouse hubs to shorten delivery cycles — a valuable advantage in fast-moving development projects.

Cost Factors and ROI Considerations

While it’s tempting to focus solely on initial costs, total cost of ownership (TCO) better reflects the true value of a dry type transformer. Factors such as energy efficiency, installation, maintenance, and downtime should be factored into ROI calculations.

| Cost Factor | Influence on ROI |

|---|---|

| Transformer efficiency class | Higher efficiency = energy savings |

| Installation environment | Indoor setup reduces ancillary costs |

| Maintenance cycle | Longer cycle = fewer service interruptions |

| Transformer lifespan | Quality construction = lower replacement cost |

A credible supplier can simulate ROI projections and energy performance comparisons to justify investment decisions — data-driven procurement at its best.

How to Send an Inquiry to a Supplier

When you’re ready to explore suppliers, don’t just ask for a quote. Instead, prepare an RFQ (Request for Quotation) that includes:

- Voltage and kVA rating

- Application environment (indoor, outdoor, marine, etc.)

- Cooling type (AN, AF, ANAF)

- Custom features (temperature sensors, enclosure type, winding material)

- Compliance standards required

This approach saves back-and-forth and ensures suppliers like qualified dry type transformer manufacturers respond with accurate, ready-to-implement proposals.

If you’re planning a project or need help specifying a custom transformer, send us your inquiry today — our engineering team will provide a detailed quotation and technical proposal.

Choosing the right dry type transformer supplier isn’t just a box to check—it’s a strategic decision that affects every level of your power system’s reliability and efficiency. The ideal partner combines engineering expertise, regulatory compliance, and customization capabilities to support your entire project lifecycle.

Whether you need a custom-designed cast resin transformer for an offshore operation or a compact VPI transformer for a commercial building, partnering with a trusted supplier ensures your energy infrastructure performs safely and efficiently for decades.

Looking for a dependable dry type transformer supplier? Contact us today to discuss your specifications and get a tailored quotation from our technical experts.

FAQ

Are dry type transformers suitable for outdoor installations?

Yes, if properly enclosed. Many suppliers offer IP-rated or weatherproof designs for outdoor environments.

How long does a dry type transformer last?

Typically 25–30 years with minimal maintenance, depending on operating conditions and load cycles.

Can I request a custom voltage ratio from a dry type transformer supplier?

Absolutely. Most professional dry type transformer supplier and manufacturers provide customized electrical parameters tailored to your system.

Are cast resin and VPI transformers the same?

They’re different manufacturing methods. Cast resin types use solid epoxy, while VPI (Vacuum Pressure Impregnated) types use resin under vacuum—both are dry-type but suited to different environments.

What kind of warranty do dry type transformer supplier usually offer?

Usually 1–3 years, extendable with maintenance agreements.