In industrial and commercial power systems, transformers aren’t just another piece of equipment—they’re the backbone of safe and efficient energy distribution. Among various options, the Cutler Hammer dry type transformers stands out for reliability, durability, and low maintenance. Whether you’re an engineer designing a new facility, a procurement specialist managing budgets, or an EPC contractor looking for dependable power solutions, choosing the right transformer matters.

This comprehensive guide explores everything you need to know about Cutler Hammer dry type transformers—from how they work and where they’re used to key technical considerations before you buy.

What Is a Cutler Hammer Dry Type Transformer?

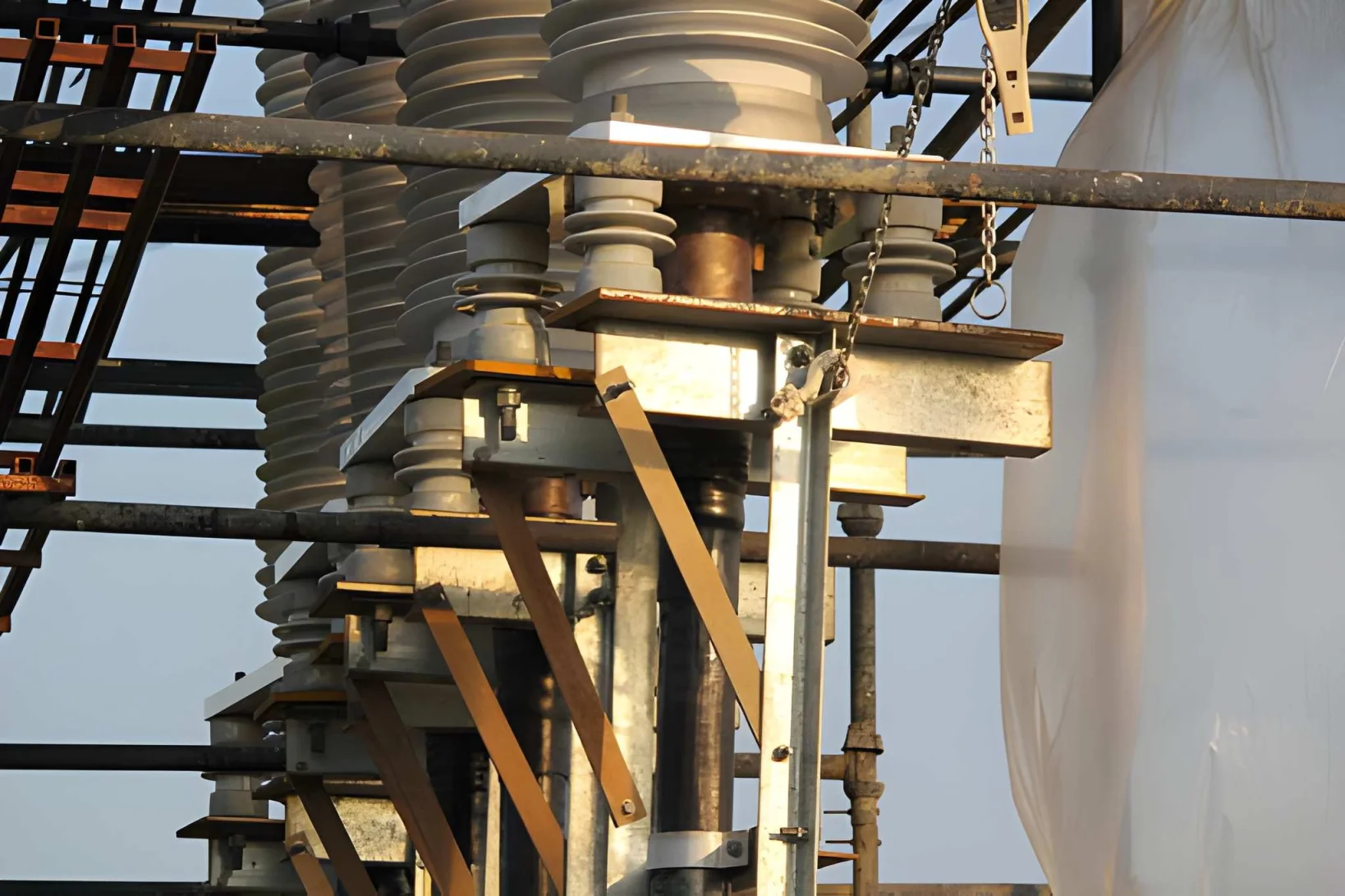

A dry type transformer, as the name suggests, doesn’t use any liquid for cooling—it relies on air circulation. The Cutler Hammer dry type transformer, manufactured under the Eaton brand, is engineered for environments where safety, low fire risk, and minimal maintenance are paramount.

Unlike oil-filled models, these transformers contain encapsulated or ventilated coils housed in a robust enclosure. Because of their self-cooling nature, they are favored in industries like manufacturing, data centers, healthcare, and commercial buildings where environmental safety and uptime are critical.

How a Dry Type Transformers Works

Dry type transformers operate on electromagnetic induction principles. Their primary coil receives alternating current (AC), creating a magnetic field that induces voltage in the secondary coil, thus transforming voltage levels for downstream applications.

Here’s a quick comparison between dry type and oil-filled transformers for context:

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling method | Air or forced air | Mineral oil |

| Maintenance | Low | Moderate |

| Fire safety | Excellent | Moderate risk |

| Installation area | Indoor/outdoor | Mostly outdoor |

| Environmental impact | Eco-friendly | Potential oil leaks |

| Cost | Slightly higher | Typically lower |

In short, while the upfront cost of a dry type transformer can be slightly higher, its reduced maintenance, enhanced safety, and environmental benefits make it a smart long-term investment.

Key Features of Dry Type Transformers

What makes Cutler Hammer transformers an industry favorite is their reliable engineering. Eaton’s design integrates decades of electrical expertise with rigorous quality testing.

Core features include:

- High dielectric strength insulation for improved performance under high voltage stress.

- Class 220°C coil insulation for extended lifespan.

- VPI (Vacuum Pressure Impregnated) and VPE (Vacuum Pressure Encapsulated) options for improved moisture resistance.

- Low noise levels, meeting NEMA and IEEE sound level standards.

- Custom kVA ratings (from 15 kVA to 2500 kVA and higher).

For buyers seeking cost-effective and reliable solutions, these transformers offer superior thermal performance and load tolerance, reducing downtime risks.

Common Applications in Industrial Settings

The Cutler Hammer dry type transformer is used in a wide range of industrial and commercial applications. It’s designed to handle variable loads and withstand harsh operating conditions.

Typical applications include:

| Industry | Common Use Case | Transformer Type |

|---|---|---|

| Manufacturing plants | Motor control centers, panelboards | VPI |

| Data centers | Power distribution units | VPE |

| Hospitals | Lighting and emergency power | General purpose |

| Mining operations | Remote power supply | Encapsulated |

| Commercial buildings | Utility rooms, HVAC systems | VPI |

If you’re managing energy distribution in any of these sectors, you know how crucial reliability and safety are. Cutler Hammer’s line of dry type transformers consistently meets those demands.

Choosing the Right Cutler Hammer Transformer Model

When selecting the right transformer, it’s not just about brand—it’s about matching the spec to the system’s needs. Consider these technical parameters:

- kVA Rating: Ensure it matches your load requirements.

- Primary and Secondary Voltage: Common configurations include 480V to 208/120V or 600V to 240/120V.

- Temperature Rise: Standard models offer 150°C or 80°C options.

- Phase Configuration: Choose between single-phase or three-phase.

- Mounting Type: Floor, wall, or pole-mounted designs.

| Specification | Standard Option | Custom Option |

|---|---|---|

| kVA rating | 15–2500 kVA | Up to 5000 kVA |

| Voltage | 480V / 600V | Custom per project |

| Insulation | 220°C class | 185°C or higher |

| Cooling | Self-cooled | Forced air |

| Frequency | 60 Hz | 50/60 Hz dual rated |

When you work with a distributor or OEM, ask whether your application requires harmonic mitigation, K-factor rated units, or NEMA 3R enclosures for outdoor use.

Cutler Hammer vs. Other Dry Type Brands

In the competitive transformer market, Cutler Hammer competes with brands like Square D, Siemens, and ABB. So, what sets it apart?

- Durability: Cutler Hammer models are known for thicker insulation coating and advanced VPI processing.

- Serviceability: Components are modular and easily accessible during maintenance.

- Compatibility: Designed to integrate with Eaton panelboards, switchgear, and MCCs.

- Global availability: Replacement parts and technical support are readily available worldwide.

| Brand | Cooling Method | Typical Use Case | Distinct Feature |

|---|---|---|---|

| Cutler Hammer | Air/vacuum | Industrial, data centers | VPI & VPE options |

| Siemens | Air | Commercial buildings | Compact footprint |

| ABB | Air | Infrastructure | High-density design |

| Square D | Air | Utility distribution | Field adjustability |

When long-term stability matters more than initial cost, industrial buyers often favor Cutler Hammer dry type transformers for their proven resilience and strong aftermarket service.

Maintenance and Lifecycle Cost Savings

While dry type transformers require less upkeep than oil-filled models, proper maintenance still maximizes longevity.

Simple maintenance tips include:

- Keep ventilation paths clear of dust and debris.

- Inspect connections for temperature rise or loose terminals.

- Schedule routine infrared thermography to detect hotspots.

- Monitor insulation resistance annually.

With diligent care, a Cutler Hammer dry type transformer can last 20–30 years while maintaining performance efficiency above 98.5%.

If you’re managing multiple power systems or planning an upgrade, investing in a dry type solution can significantly cut operating costs and improve reliability.

Need a quote for bulk orders or project-based procurement? Contact our technical sales team today for specification support and best pricing.

Environmental and Safety Benefits

From a sustainability standpoint, dry type transformers are a greener alternative. They contain no oil, thus eliminating leak and disposal risks. The epoxy resin insulation used in VPE units resists moisture, making them ideal for coastal regions or humid environments.

Moreover, their low flammability and self-extinguishing insulation make them compliant with modern NFPA and UL standards—key for hospital, high-rise, and data center installations where fire safety is non-negotiable.

Ordering and Customization Options

Cutler Hammer dry type transformers come in both standard-stock and custom-engineered configurations. Customization may include:

- Harmonic mitigation for nonlinear loads.

- K-rated designs for variable frequency drives (VFDs).

- Aluminum or copper windings depending on cost and performance.

- Soundproof or vibration-dampening enclosures for sensitive environments.

- Integration with Eaton switchgear or MCC systems.

When ordering, providing detailed load data and environmental conditions helps ensure you receive the right model.

For distributors and industrial buyers, minimum order quantities (MOQs) and lead times vary by model—typically ranging from 4 to 8 weeks for large-capacity units.

Choosing a Cutler Hammer dry type transformer isn’t just buying equipment—it’s an investment in safety, efficiency, and longevity. These transformers meet demanding industrial standards, adapt to diverse voltage requirements, and ensure operational continuity in mission-critical environments.

So, if your upcoming project demands low maintenance, high reliability, and eco-friendly power distribution, the Cutler Hammer dry type transformer is a dependable fit.

Need help specifying the right model or getting bulk pricing for your project? Reach out to our engineering team today for a professional consultation or detailed quotation.

FAQ

Are Cutler Hammer and Eaton the same?

Yes. Eaton acquired Cutler Hammer, and all Cutler Hammer transformers are now branded as part of Eaton’s product line.

Can I use a dry type transformer outdoors?

Absolutely. With a NEMA 3R or 4 enclosure, they can safely operate outdoors under various weather conditions.

What’s the typical lifespan of a Cutler Hammer dry type transformer?

With routine maintenance, you can expect 20–30 years of reliable service life.

What’s the difference between VPI and VPE?

VPI (Vacuum Pressure Impregnated) provides insulation through varnish, while VPE (Vacuum Pressure Encapsulated) fully seals windings in epoxy, offering superior protection from moisture and contaminants.

Do you provide technical customization or OEM support?

Yes. Many distributors offer OEM engineering support and full documentation to align with your installation and compliance requirements.

Table of Contents

Ready to explore your options?

Contact us today for a custom Cutler Hammer dry type transformers quotation — because the right transformer doesn’t just move power, it powers your entire business forward.