OVERVIEW

Core manufacturing

All the silicon steel sheet for cores of dry-type transformer are cutted by GEORG Germany automatic cutting machine. The burr of silicon steel sheet is less than 0.02 mm and the angle error is less than ±0.005. Fine quality and high magnetic inductivity silicon steel sheet from “Baogang” to reduce the no-load loss and noise. H class insulation duct is applied inside the core, H-glue is applied to strengthen the limb, so that the transformer can work safely for a long time. The iron core adopts five-stage stepping joint, the clamp force is adjustable. The precise positioning guarantees the horizontal and vertical directions. Elastic bearing assembly is adopted between the coils and iron core, and a stable pressure caused by a dish spring is applied. So that the transformer have high cushioning ability and high shock resistance.

Coil

The high voltage coils are sectional cylinder coils with thin insulation to be casted in vacuum. Axial air ducts are applied in large capacity windings. The coils can withstand high voltage and have low partial discharge. The coils have high fire resistance capability, damp proof ability, dust proof ability and fine cooling system. The low voltage are copper foil coils. Solidify the casting by applying DMD pre-impregnated heat distribution method. The additional loss is low and the short-circuit resistance is high.

Thin insulation

Both the high voltage winding and low voltage winding are enclosed by film resin which is reinforced by compound silicon-hydride glass-fiber which can withstand a temperature of 200 ℃ .The glass-fiber greatly reinforces the mechanical strength of the enclosure layer of resin. The resin layer is tenacious, thin and elastic, so ti can expand or shrink with the winding. This can prevent the casting layer from splitting. Because the resin layer is very thin , the temperature difference between the two sides of resin layer is very small. This helps the heat radiating of winding. In addition, axial air duct can be set in the inner space of winding to increase the radiating surface.

Casting

The finished coils are processed in the VACUUMPEK3/150E(HEDRICH Germanny) vacuum casting pot and the casting process is controlled by computer. Cibasc F epoxy resin (Swiss), solidified agent and glass-fiber are applied to reinforced. Exclude the air in the liquid epoxy resin with the film degassing method, which makes sure that there is no cavity in the casting coils. This can guarantee a low partial discharge( ≤ 5pc) or zero partial discharge.

Enclosure

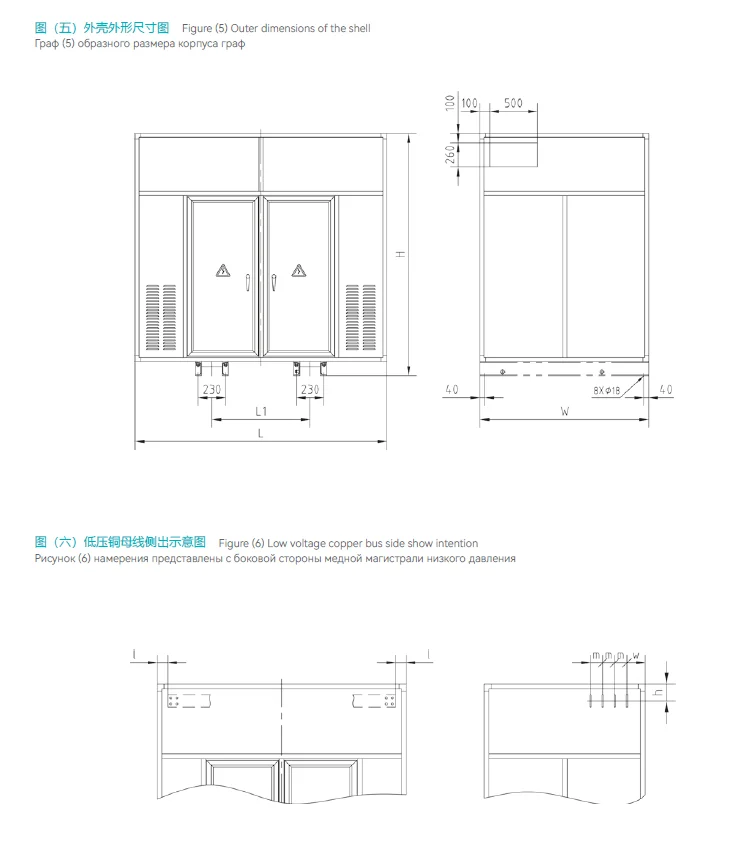

Framwork modular aluminum alloy casing is applied. The transformer and low voltage distribution panel can be installed in the same distribution room. According to the customer’s requirements to deploy the high/low voltage bus outlet. The aluminum alloy casing is compact, nice looking and fine rigidity. For the indoor transformer, IP20 protecting casing is usually adopted. This kind of casing can prevent a particle with diameter larger than 12mm from entering the casing. For the outdoor transformer, IP23 protecting casing is a good choice.

Note: IP23 casing will cause the decrease of heat radiating ability of transformer. So the capacity will be reduced by 5% for a small capacity transformer and 10% for a large capacity transformer.

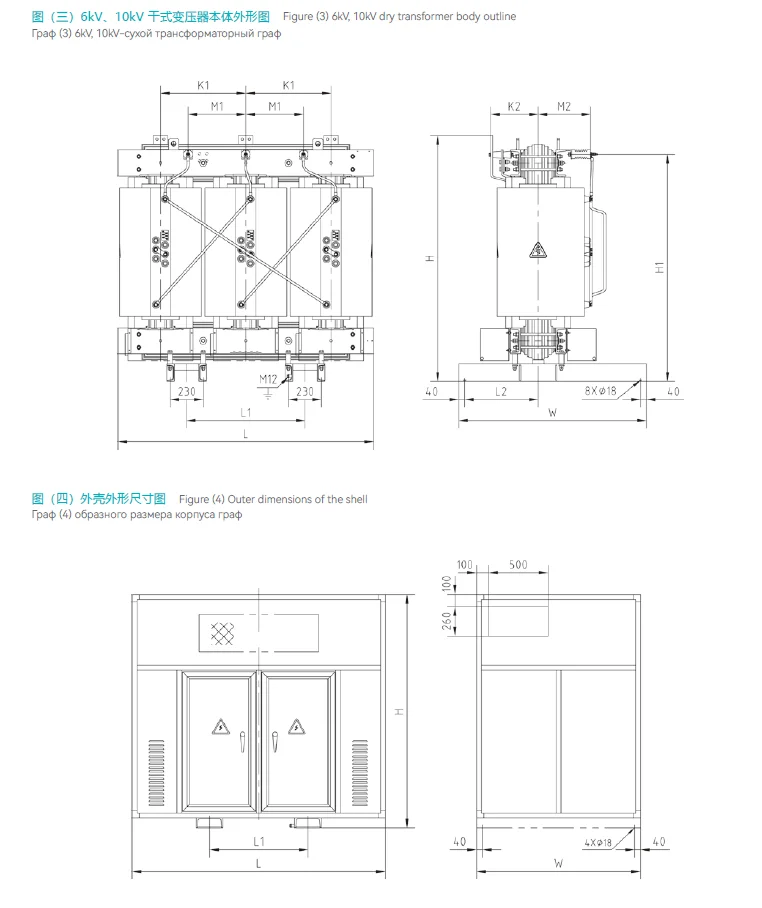

Product Structure Diagram

Note: Due to the constant update of the product, the dimensions and weight of the product in the table will change, please refer to the dimensions provided at the time of booking.