Transformers are the silent heroes behind modern industry — quietly ensuring electricity flows safely, efficiently, and reliably. Among them, the dry type transformer has become increasingly popular in industrial, commercial, and renewable energy applications. But what makes it different from the more traditional oil-filled transformers? Why are engineers and procurement managers leaning toward this technology?

Let’s explore everything you need to know about dry type transformers, from performance and safety to installation and cost-saving potential.

What Is a Dry Type Transformer?

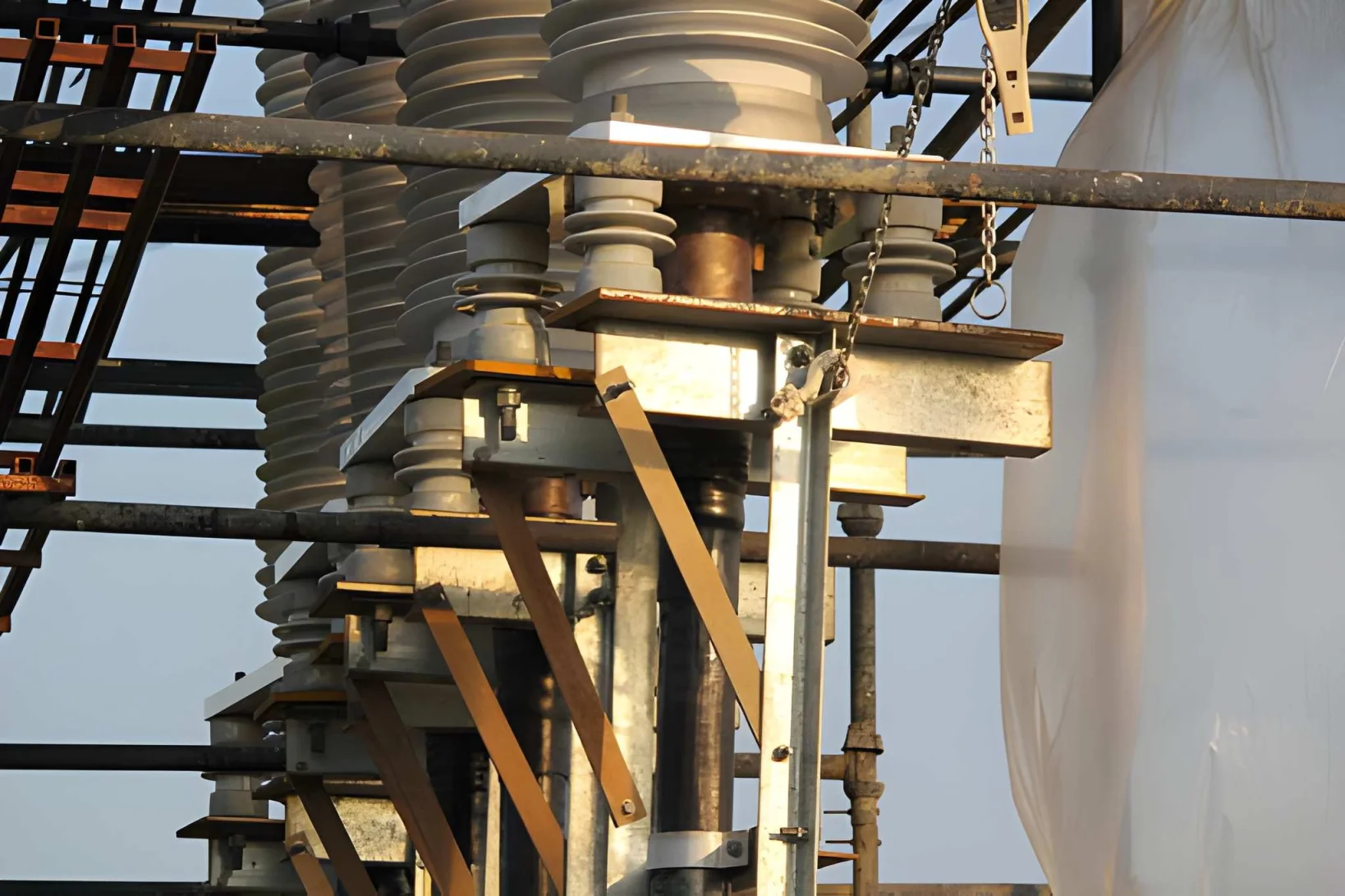

A dry type transformer is a power transformer that uses air instead of oil or liquid for cooling. Unlike oil-immersed transformers, the dry type version relies on natural air ventilation or forced air systems to dissipate heat from the windings and core.

This means the transformer operates without combustible materials, making it remarkably safe for indoor installations — such as hospitals, high-rise buildings, data centers, and manufacturing plants.

Key Features:

- Air-cooled or resin-encapsulated design (commonly called cast resin dry type transformer).

- Suitable for humid, dusty, or fire-sensitive environments.

- Easier maintenance with no risk of oil leakage.

- Long operational lifespan with stable performance.

| Type | Cooling Method | Applications | Maintenance Needs |

|---|---|---|---|

| Cast resin dry type transformer | Air or natural convection | Indoor, commercial, renewable projects | Low |

| VPI (Vacuum Pressure Impregnated) dry type transformer | Forced air | Industrial, marine, or mining | Low to medium |

Why Enterprises Are Choosing Dry Type Transformers

Across industries, dry type transformers are becoming the preferred solution for modern electrical infrastructure. From industrial engineers focused on performance to procurement specialists managing long-term operating costs, the reasons behind this shift go far beyond safety. Let’s take a closer look at the technical, economic, and environmental factors driving adoption.

1. Enhanced Fire Safety and Compliance

Safety is often the first reason enterprises replace oil-immersed units with dry type transformers. Because these transformers use air or epoxy resin instead of oil, there is no flammable medium involved. This makes them the optimal choice for installations in:

- Data centers

- Hospitals

- High-rise buildings

- Underground substations

- Renewable energy substations

Most dry type units comply with fire-resistance classifications like F1, C2, and E2, meaning they won’t sustain flame or release toxic gases under short-circuit or overload conditions. For companies building energy infrastructure under NFPA, IEC, or UL safety codes, this compliance reduces both regulatory risk and insurance cost.

In other words, no oil means no risk of explosion, and no oil-related maintenance emergencies—a fact facility managers love.

2. Eco-Friendly Operation and Sustainability Goals

In procurement and engineering tenders, one of the fastest-growing priorities is sustainability. Dry type transformers are environmentally safer since they:

- Eliminate oil leaks and soil contamination.

- Require minimal maintenance waste.

- Operate quietly, lowering noise pollution.

- Support ISO 14001 environmental management systems.

Many companies also list “zero-emission equipment” in their green procurement policies—making dry type transformers a strategic match. With the global push for low-carbon infrastructure, switching to dry type distribution transformers aligns with ESG and decarbonization initiatives across industries like utilities, construction, and manufacturing.

3. Easier Maintenance and Lower Lifecycle Costs

Procurement teams and plant engineers appreciate that dry type transformers are virtually maintenance-free. With no oil to test, filter, or replace, maintenance budgets drop dramatically.

Additionally:

- Dust-resistant and sealed resin insulation prevents corrosion or moisture absorption.

- Only basic inspection, temperature checks, and airflow cleaning are required.

- Fewer moving parts reduce the risk of unplanned downtime.

The long-term Total Cost of Ownership (TCO) advantage becomes clear: even if the upfront investment is 10–20% higher than oil-filled models, operational savings often repay that difference within 3–5 years. For multi-site enterprises, that translates into substantial annual energy and service savings.

| Cost Factor | Oil-Filled Transformer | Dry Type Transformer |

|---|---|---|

| Purchase cost | Medium | Slightly higher |

| Maintenance | Regular oil testing | Minimal |

| Fire protection system | Required | Optional |

| Downtime risk | Moderate | Very low |

| Environmental compliance cost | Higher | Negligible |

4. Compact Design and Installation Flexibility

When space is limited, or site accessibility is difficult, the compact footprint of a cast resin dry type transformer becomes a major advantage. These units can be installed:

- Directly inside buildings

- Close to load centers

- In basements, tunnels, or rooftops

Because they require no oil containment pit or ventilation system for gas release, installation costs are lower. Construction schedules shorten because civil and safety infrastructure is simplified.

For engineers, flexibility also extends to custom configurations—like multiple secondary windings, enclosure ratings up to IP54, and integration with smart monitoring systems (IoT-based sensors that track temperature, load, and moisture). This adaptability makes the technology suitable for renewable energy, marine vessels, metro stations, and industrial control rooms alike.

5. High Efficiency and Energy Loss Reduction

Modern dry type transformer manufacturers now produce units that meet or exceed DOE 2016 or IEC 60076-20 efficiency standards. Through the use of low-loss magnetic cores and optimized copper windings, they deliver minimal no-load and load losses.

This efficiency matters — especially in large facilities running 24/7 operations. Over the lifespan of a 2500 kVA transformer, reducing just 0.5% of energy loss can save tens of thousands of kilowatt-hours per year, directly cutting electricity costs and greenhouse gas emissions.

Engineers also find that dry type transformers handle overload conditions better, thanks to advanced thermal design and improved airflow channels that dissipate heat quickly and uniformly.

6. Reliability and Long Service Life

Unlike oil-filled types that degrade or oxidize over time, dry type transformers maintain consistent performance for decades. Because there is no oil contamination or sludge buildup, insulation life remains stable. Many high-quality models easily exceed 30–40 years of service with minimal degradation.

Additionally, the epoxy or silicone resin encapsulation provides strong resistance to vibration, chemical vapors, and high humidity — conditions often present in steel plants, chemical factories, and marine installations.

7. Compatibility With Digital Power Systems

As power systems evolve toward smart grids, digital monitoring and predictive maintenance are taking center stage. Dry type transformers now often include:

- Temperature sensors integrated into windings.

- IoT gateways for real-time data transmission.

- SCADA or building automation system compatibility.

For managers overseeing remote or mission-critical sites, this means fewer inspections and faster detection of potential faults — ensuring higher uptime and operational reliability.

8. Manufacturer Availability and Standardization

Globalization has made it easier to source certified dry type transformers from reliable suppliers. Key standards such as IEC 60076, ANSI C57, and EN 50541-1 have led to more competitive pricing and predictable quality.

Many manufacturers now provide custom engineering support to align transformer ratings with local grid codes or voltage specifications — perfect for international procurement projects and EPC contracts.

Ready to explore your options?

Contact us today for a custom dry type transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.

Dry Type Transformer Applications Across Industries

Dry type transformers support a wide range of industrial, commercial, and infrastructure applications. They serve as critical components wherever safety, performance, and reliability intersect.

| Industry | Typical Application | Recommended Rating |

|---|---|---|

| Data centers | Power distribution, UPS isolation | 1000–2500 kVA |

| Renewable energy | Wind and solar substations | 500–3000 kVA |

| Manufacturing plants | Motor drives, heavy load systems | 1500–5000 kVA |

| Commercial buildings | HVAC, lighting, elevators | 500–2000 kVA |

| Transportation | Railways, metros, airports | 1000–3500 kVA |

By aligning the transformer’s design with the application’s demand, engineers can ensure higher efficiency and reduce the carbon footprint of operations.

If your project requires custom-designed specifications or certifications (like ANSI, IEC, or UL), consider requesting a dry type transformer manufacturer that offers tailored engineering solutions.

Comparing Dry Type vs. Oil-immersed Transformers

Selecting the right transformer depends on your operational environment and safety requirements. Below is a quick comparison to help guide your decision.

| Aspect | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling medium | Air | Mineral or synthetic oil |

| Maintenance | Minimal | Requires oil checks |

| Fire risk | Very low | High |

| Installation | Indoor or outdoor | Mostly outdoor |

| Efficiency | Slightly lower (1–2%) | Very high |

| Environmental impact | Eco-friendly | Risk of oil leakage |

| Initial cost | Moderate to high | Moderate |

While oil-immersed transformer still dominate high-voltage outdoor networks, dry type transformers are winning favor in medium-voltage commercial and industrial power distribution systems where safety and space are priorities.

How to Select the Right Dry Type Transformer

Choosing the right transformer for your project isn’t just about capacity — it’s about strategic planning and lifecycle value. Here’s what engineers and procurement specialists should consider:

- Power Rating and Load Type – Match the kVA rating to your system’s real demands, considering future expansion.

- Ambient Conditions – Select suitable insulation classes for humid or corrosive environments.

- Efficiency Class – Look for transformers meeting DOE or IEC 60076 efficiency standards.

- Cooling Type – Decide between natural air cooling (AN) or forced air cooling (AF) systems.

- Customization Options – Ask suppliers about enclosures, tap changers, and protection levels like IP21 or IP54.

Pro tip: Always request a technical data sheet before ordering to ensure compatibility with existing switchgear and power distribution equipment.

From data centers to renewable energy systems, Dry Type Transformer are bridging the gap between reliability and safety. As industries move toward sustainable, maintenance-free, and digital-ready power infrastructure, their importance will only grow.

Whether you’re an electrical engineer designing a new power distribution line or a procurement manager sourcing high-efficiency transformers, investing in a dry type transformers ensures peace of mind — for both performance and long-term safety.

Ready to explore your options? Contact us today for a custom dry type transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.

FAQ

Are dry type transformers safe to install indoors?

Yes, they are specifically designed for indoor operation. With no oil or combustible materials, they pose minimal fire hazard.

What sizes are available for industrial use?

Dry type transformers range from a few hundred kVA to over 10 MVA, depending on the manufacturer and design.

How long does a dry type transformer last?

With proper ventilation and cleaning, most units last 25–35 years without major maintenance.

Can dry type transformers be used outdoors?

Yes, if enclosed in weatherproof housings with adequate IP ratings.

What standards should I look for when purchasing?

Common standards include IEC 60076, ANSI C57, and UL certifications.

Table of Contents

Ready to explore your options?

Contact us today for a custom dry type transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.