When it comes to industrial power distribution, dry type transformer stand out as a reliable, low-maintenance, and safe solution. Whether you’re a plant engineer, facility manager, or procurement specialist, understanding different dry type transformer types helps you make smarter investment and design decisions.

Let’s dive into what makes dry type transformers unique, explore the major types available, and discuss how to choose the right one for your next power project.

What Is a Dry Type Transformer?

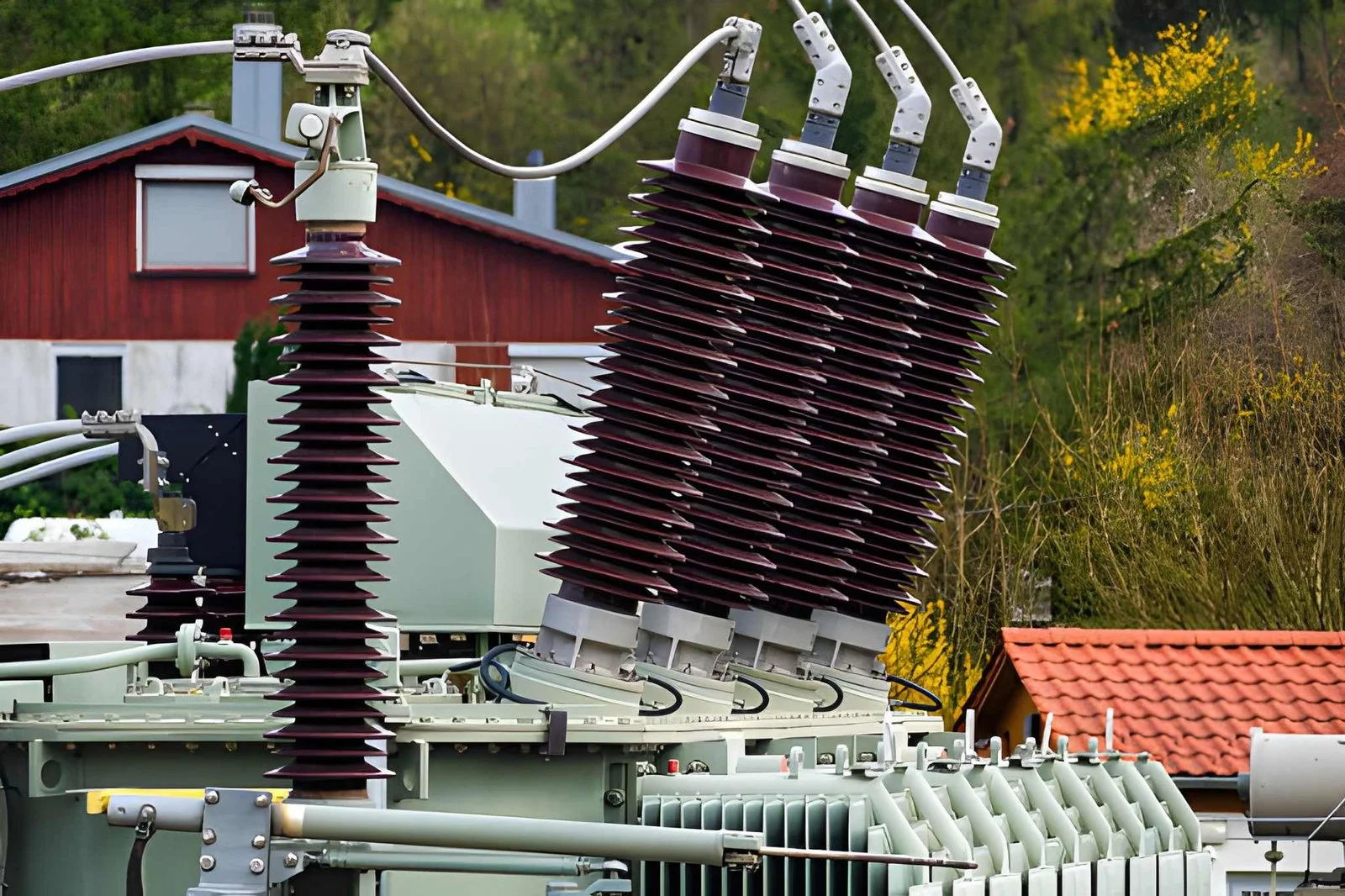

Unlike oil-filled transformers, dry type transformers use air instead of liquid for cooling. This means they’re safer, environmentally friendly, and perfect for indoor applications where fire protection and cleanliness matter most.

They are typically used in:

- Commercial buildings

- Data centers

- Manufacturing plants

- Renewable energy installations

- Hospitals and shopping complexes

Because they don’t contain oil, there’s no risk of leakage or environmental contamination. Plus, their long lifespan and minimal maintenance make them cost-effective over time.

Major Dry Type Transformer Types

Dry type transformers come in several configurations, each designed for specific performance and environmental needs. Here’s a breakdown of the key dry type transformer types you’ll encounter in the market.

1. Cast Resin Dry Type Transformer (CRT)

Cast resin transformers are among the most popular types used in modern industrial settings. Their windings are encapsulated in epoxy resin, preventing moisture, dust, and chemical ingress.

They’re ideal for humid or coastal areas and areas prone to pollution or vibration.

| Feature | Cast Resin Transformer |

|---|---|

| Cooling System | Air Natural (AN) or Air Forced (AF) |

| Insulation | Epoxy resin |

| Maintenance | Very low |

| Best For | Indoor use, humid environments |

| Typical Voltage Range | Up to 36kV |

Example Application: wind farms, marine industries, and chemical processing plants.

2. Vacuum Pressure Impregnated Transformer (VPI)

The VPI dry type transformer uses a polyester or silicone resin coating applied under vacuum and pressure. It provides strong protection against contaminants while maintaining excellent heat dissipation.

This type strikes a good balance between performance and cost-efficiency.

| Feature | VPI Transformer |

|---|---|

| Cooling System | Air Natural / Air Forced |

| Protection | Moderate moisture resistance |

| Best For | Indoor, mildly humid environments |

| Insulation Material | Polyester resin |

| Maintenance | Easy field repair and replacement |

Key Advantage: The insulation system allows high mechanical strength, making VPI transformers suitable for heavy-duty industrial loads.

3. Vacuum Pressure Encapsulated Transformer (VPE)

Closely related to VPI, the VPE dry type transformer takes protection further. Here, windings are fully encapsulated with resin to ensure superior moisture resistance and durability.

These transformers find wide application in coastal regions or outdoor installations with moderate exposure to weather conditions.

| Feature | VPE Transformer |

|---|---|

| Moisture Resistance | High |

| Cooling System | Air-cooled |

| Best For | Outdoor or coastal installations |

| Maintenance | Low |

| Lifespan | Long-term protection from corrosion |

Procurement managers often choose VPE transformers when reliability is non-negotiable and downtime costs are high.

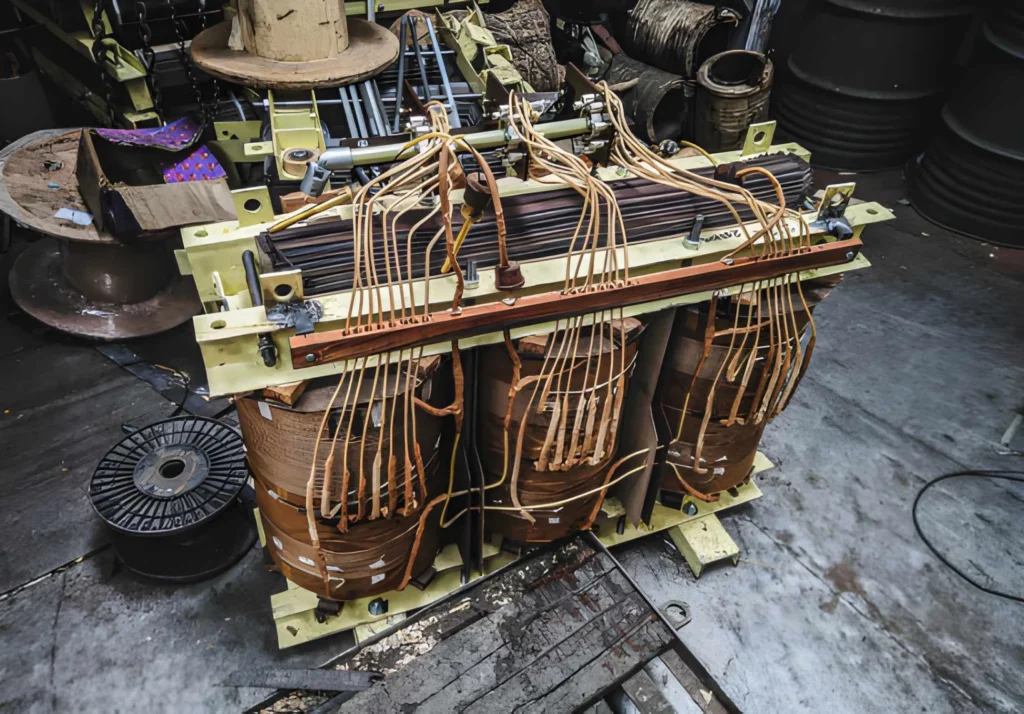

4. Resin-Bonded Transformer (RBT)

The resin-bonded type uses a different technique where the coil windings are pre-impregnated with resin and cured. The result is a robust, rigid structure that can withstand thermal expansion and mechanical shocks.

These units are common in mines, metro systems, and renewable energy projects.

| Parameter | RBT Transformer |

|---|---|

| Mechanical Strength | Excellent |

| Cooling Type | Air Natural |

| Insulation System | Thermosetting resin |

| Ideal Environments | Harsh, vibration-prone sites |

| Failure Rate | Very low |

Quick Tip for Engineers: RBTs are especially beneficial in high-vibration environments where standard epoxy-cast units may crack under stress.

Why Choose Dry Type Transformers?

From an engineering and safety perspective, dry type transformers deliver multiple operational advantages:

- Fire safety: No flammable oil or risk of explosions.

- Eco-friendly: Zero risk of oil leakage and minimal environmental impact.

- Compact design: Easier to install in confined spaces.

- Minimal maintenance: No oil sampling or filtration required.

- Long service life: With proper ventilation, many operate for decades.

Because of these benefits, many industries are shifting from oil-filled to dry type transformers, especially as global regulations tighten around fire codes and environmental safety.

If your business prioritizes operational safety and sustainability, it’s worth sending an inquiry to get a company quote or consultation from a trusted transformer manufacturer.

Choosing the Right Dry Type Transformer Types for Your Project

Selecting the right transformer depends on multiple factors, including capacity, environment, installation location, and load type. Here’s a quick reference:

| Application | Recommended Transformer Type | Key Consideration |

|---|---|---|

| Indoor distribution | VPI or Cast Resin | Low noise, compact size |

| Outdoor substations | VPE | Moisture resistance |

| Coastal areas | Cast Resin | Anti-corrosion |

| Renewable energy | RBT or CRT | High reliability |

| Industrial plants | VPI | Mechanical toughness |

Bonus Tip: Always verify compliance with relevant standards such as IEC 60076-11 or ANSI C57.12.01 when evaluating transformer suppliers.

Emerging Trends in Dry Type Transformer Technology

The transformer industry is evolving fast. Here are a few upcoming trends worth noting:

- Smart transformers equipped with temperature and load sensors for real-time monitoring.

- Eco-resin materials replacing synthetic resins for even greener production.

- Flexible modular designs that simplify installation and maintenance.

- Integration with renewable energy systems, such as solar and wind networks.

These innovations show how dry type transformers are becoming smarter, more efficient, and easier to manage remotely — perfect for the Industry 4.0 era.

B2B Considerations for Procurement

From a buyer’s standpoint, here are critical factors when sourcing dry type transformers:

- Vendor reliability: Look for ISO-certified manufacturers with proven track records.

- Customization: Confirm that the vendor offers adjustable voltage ratings and enclosures.

- After-sales support: Maintenance and part availability are essential.

- Price vs. lifecycle cost: Cheap units might cost more in downtime and repairs later.

Before finalizing a purchase, always request detailed technical datasheets and performance test reports. Working with professional suppliers ensures you meet both safety and operational efficiency goals.

From cast resin to VPI dry type transformers, each type offers distinct strengths that cater to specific industries and conditions. By understanding their characteristics, engineering teams and procurement professionals can make data-driven purchasing decisions that enhance safety, reliability, and long-term performance.

If you’re planning to upgrade or expand your energy distribution systems, now is the time to explore modern dry type transformer types with your preferred manufacturer. Request a technical quote today and find the best configuration to meet your power goals.

FAQ

Are dry type transformers more expensive than oil-filled ones?

They can be slightly more expensive upfront, but lower maintenance and installation costs make them cheaper over their lifetime.

Can I use a dry type transformer outdoors?

Yes. VPE and specially enclosed CRT units are designed for outdoor use with proper weather protection.

What maintenance do they require?

Usually just periodic dust cleaning, ventilation checks, and insulation testing.

How long do dry type transformers last?

Typically 20–30 years, depending on load conditions and environment.

Can I replace an existing oil-filled transformer with a dry type one?

Yes, but verify that the installation site offers adequate airflow and meets your kVA requirements.

Table of Contents

Ready to explore your options?

Contact us today for a custom Dry-Type Transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.