Dry Type Transformers are the silent workhorses of modern power systems. Whether you’re designing a hospital electrical network, an industrial plant, or a renewable energy substation, choosing the right transformer is critical for efficiency, safety, and long-term reliability. Among the various types available, dry type transformers have become a preferred choice in many commercial and industrial applications due to their safety, eco-friendliness, and low maintenance.

But what exactly are dry type transformers? How do they work, and why do engineers and procurement managers increasingly prefer them over oil-filled models? Let’s explore everything you need to know.

Understanding the Basics What Is a Dry Type Transformer?

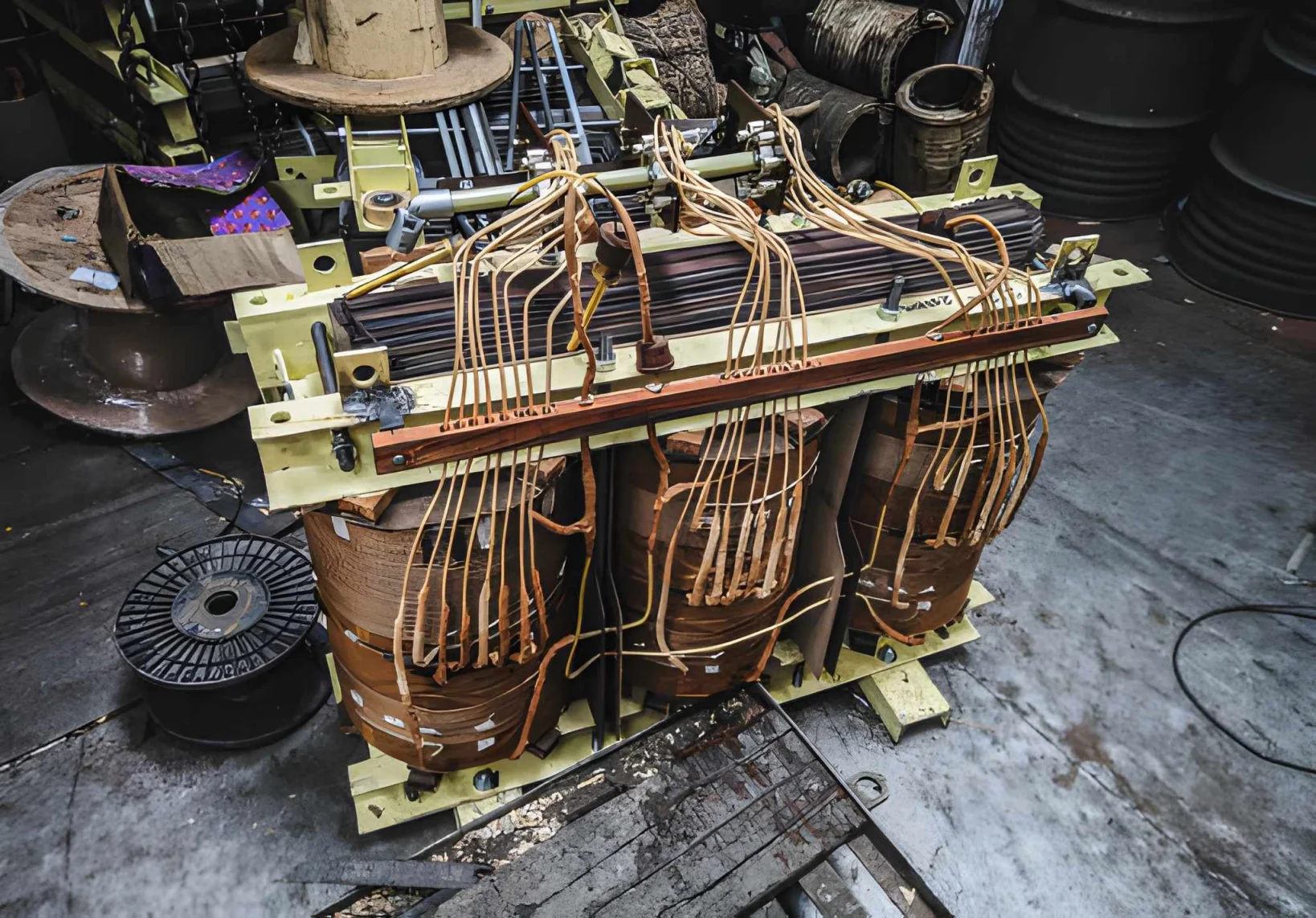

A dry type transformer is a transformer that uses air as the cooling medium instead of oil or other liquid insulators. The coils and core are kept within a sealed enclosure and cooled by natural air circulation or forced ventilation.

Unlike oil-immersed transformers, which rely on oil for insulation and cooling, dry type transformers are built using cast resin or vacuum pressure impregnated (VPI) windings, making them non-flammable and environmentally safe.

Here’s a simple comparison of both types:

| Feature | Dry Type Transformer | Oil-immersed Transformer |

|---|---|---|

| Cooling Medium | Air/Natural or Forced | Mineral or Synthetic Oil |

| Safety | High (Non-flammable) | Requires Fire Protection |

| Maintenance | Low | Moderate to High |

| Environmental Impact | Eco-friendly | Potential Oil Leakage |

| Installation Area | Indoor or Outdoor (with enclosure) | Primarily Outdoor |

| Typical Usage | Commercial, Industrial Buildings | Power Distribution Systems |

In short, dry type transformers are designed for safety, reliability, and sustainability—perfect for densely populated or enclosed environments.

How Does a Dry Type Transformer Work?

The working principle is simple yet brilliant. Electrical energy passes through the primary winding, creating a magnetic field that induces voltage in the secondary winding. Instead of oil, air cools and insulates the system.

There are two main cooling methods:

- AN (Air Natural) – Natural air flow cools the transformer. Ideal for light-to-medium loads.

- AF (Air Forced) – Fans increase airflow for heavy-duty industrial applications.

By removing liquid insulation, these transformers eliminate risks of leaks, fire, and contamination, making them ideal for mission-critical operations like airports, data centers, and hospitals.

Types of Dry Type Transformers

To meet varied project demands, manufacturers offer different designs of transformer types, mainly classified by the insulation method:

| Type | Description | Common Applications |

|---|---|---|

| Cast Resin Transformer (CRT) | Windings are encapsulated in epoxy resin. High resistance to moisture and dust. | Marine, mining, offshore sites |

| Vacuum Pressure Impregnated (VPI) | Windings dipped in varnish and cured under vacuum. Cost-effective and durable. | Commercial facilities, factories |

| Vacuum Pressure Encapsulated (VPE) | Provides added environmental protection via resin coating. | Outdoor or humid environments |

Each variant offers a unique balance between cost, protection, and performance. For engineers, evaluating site conditions—such as humidity, ventilation, and load characteristics—can ensure the best selection.

Advantages of Dry Type Transformers for Industrial and Commercial Use

Let’s talk benefits—because when you’re purchasing equipment worth thousands of dollars, every advantage counts.

- Enhanced Safety: Non-flammable and resistant to fire or explosion hazards.

- Eco-Friendly: No oils, no leaks, no pollution.

- Low Maintenance: Fewer moving parts, no oil replacement cycles.

- Better Flexibility: Can be installed indoors in confined areas or near sensitive equipment.

- Long Service Life: Designed to withstand thermal and mechanical stresses.

These advantages make dry type transformers the go-to solution for B2B sectors like real estate developments, metro systems, renewable energy, and data centers.

Ready to explore your options?

Contact us today for a custom dry type transformers quotation — because the right transformer doesn’t just move power, it powers your entire business forward.

Dry Type Transformers Common Applications

Dry type transformers have become the preferred solution for a wide range of industrial, commercial, and infrastructure projects, largely because they deliver strong performance with high safety and low environmental impact. Below is a deeper look into where and why these transformers are used—and how they address specific technical challenges across sectors.

1. Commercial Buildings and Infrastructure

Modern buildings like shopping malls, hotels, hospitals, and office towers depend on continuous, reliable power. Dry type transformers are ideal here because they can be installed close to load centers—such as electrical rooms or basement substations—without fire or leakage risks.

They also operate quietly and efficiently, reducing noise disturbance in places like hospitals, schools, and luxury hotels. Since no oil or combustible liquids are present, facility managers also save on fire insurance costs and safety compliance.

Example: A hospital may use multiple 1,250 kVA VPI dry type transformers to feed critical medical imaging systems, lighting circuits, and laboratory equipment—all within the same building floor, eliminating the need for outdoor transformer yards.

| Benefit | Why It Matters |

|---|---|

| Fire safety | Non-flammable and suitable for indoor locations |

| Space optimization | Compact design enables installation in basements or technical rooms |

| Low noise levels | Ideal for hospitals, schools, and commercial complexes |

| Reduced insurance cost | Meets fire safety codes such as UL, IEC, or ANSI standards |

2. Industrial and Manufacturing Facilities

Factories and process plants require steady power under demanding conditions. Environments with dust, vibration, and high ambient temperatures demand transformers that are rugged and low-maintenance.

Dry type transformers—especially cast resin transformers (CRT) with epoxy insulation—fit perfectly. They handle frequent load variations caused by motors, compressors, and automated lines. Since no oil is present, plant operators save valuable time and cost on periodic fluid testing or replacement.

Popular industries using dry type transformers:

- Steel and cement plants

- Automotive production lines

- Pulp and paper mills

- Petrochemical processing sites

In these environments, cast resin encapsulation prevents moisture ingress, reducing risk of dielectric failure even under extreme load stress.

3. Renewable Energy and Power Distribution

With the global shift toward clean energy, dry type transformers are becoming the backbone of wind farms, solar farms, and battery energy storage systems (BESS). Their robust insulation and resistance to dust and moisture make them perfect for remote outdoor deployments.

In photovoltaic (PV) installations, they connect inverter outputs to grid feeders, stepping up the voltage for long-distance distribution. In wind turbines, dry type transformers are often installed within nacelles or towers, where space and fire safety are critical.

Key advantages in renewable applications:

- Withstands wide temperature ranges (-25°C to +45°C)

- Works in high humidity and saline coastal air

- Compatible with smart grid monitoring systems (SCADA integration)

- Eliminates oil spill risk, protecting natural environments

If your company develops renewable EPC or grid-tied projects, choosing dry type transformers can help meet strict sustainability and safety standards—while improving overall system reliability.

4. Transportation and Metro Systems

Metro networks, tunnels, airports, and railway systems all rely on dry type transformers due to space constraints and safety regulations. Fire safety standards such as EN 45545-2 for rail and NFPA 130 for transit systems require the use of non-oil-filled equipment.

These transformers power escalators, lighting, ventilation, signaling, and auxiliary systems in transportation hubs. Their low noise and vibration characteristics make them ideal for underground or enclosed stations.

Example Application:

A metro station substation may use multiple 1,000–2,500 kVA dry type transformers with forced air cooling to handle peak passenger loads safely.

5. Data Centers and IT Infrastructure

Data centers demand uninterrupted, clean, and stable power 24/7. Dry type transformers provide isolation from voltage spikes and harmonics while ensuring quick temperature recovery during rapid load fluctuations.

Additionally, because they are oil-free, there’s zero risk of contamination inside server halls or battery storage rooms. Operators benefit from lower maintenance and easier compliance with LEED and ISO 50001 energy management certifications.

| Data Center Needs | Dry Type Transformer Advantage |

|---|---|

| Continuous uptime | Stable voltage regulation under varying loads |

| Energy efficiency | Low no-load and copper losses |

| Fire protection | No flammable liquids |

| Remote monitoring | Integrates with building management systems (BMS) |

Interested buyers often select high-efficiency cast resin transformers that come pre-fitted with temperature sensors and IoT modules for continuous thermal diagnostics.

6. Marine, Offshore, and Mining Environments

In harsh environments such as marine decks, oil rigs, and underground mines, reliability under challenging conditions is non-negotiable. Dry type transformers are the first choice because their encapsulated design resists salt corrosion, humidity, and dust.

For example, VPE or CRT transformers inside a ship’s power distribution network handle load variations from pumps, lighting, and navigation instruments. In mining operations, they’re often mounted near drilling or conveyor systems, ensuring worker safety where flammable gases may exist.

Environment-tested specifications include:

- Class H insulation for high temperature endurance

- IP23/IP54 enclosures for dust and water resistance

- Resistance to saline and chemical exposure

7. Public Utilities and Urban Power Distribution

Municipal substations, smart grids, and campuses are transitioning to dry type distribution transformers due to improved lifecycle safety and ease of operation. They’re particularly effective in densely populated cities, where oil-based solutions pose environmental and safety risks.

They can be integrated directly into prefabricated or containerized substations, making installation faster and more modular for developers.

Typical uses:

- Residential distribution networks

- Public lighting systems

- Microgrid and local substation upgrades

For city planners and EPC contractors, this technology supports low-carbon goals while simplifying electrical infrastructure maintenance.

So, whether you’re powering an industrial compressor, hospital wing, or offshore platform, dry type transformers offer the right blend of performance, safety, and sustainability. Their widespread adoption across energy, manufacturing, transport, and critical infrastructure sectors proves one thing—they’re not just an alternative; they’re becoming the industry standard for modern power systems.

If you’re planning a new installation or product specification, contact your trusted supplier to get a customized dry type transformer solution aligned with international standards like IEC 60076-11 or IEEE C57.12.01.

Key Specifications Should Consider

Before placing an order, pay attention to technical specifications:

| Specification | Typical Range | Notes |

|---|---|---|

| Power Rating | 50 kVA – 10,000 kVA | Choose based on load profile |

| Voltage Class | Up to 36 kV | Higher ratings available for custom builds |

| Insulation Class | Class F (155°C) / Class H (180°C) | Defines thermal limits |

| Cooling Method | AN / AF | Determines load capacity |

| Protection | IP20, IP23, or custom enclosures | Adjust for dust or moisture protection |

| Frequency | 50/60 Hz | Dependent on region/application |

Discuss these details with your procurement or engineering team to ensure compatibility with existing switchgear and protection devices.

Dry Type Transformers vs Cast Resin Transformers: Are They the Same?

Many engineers use the terms interchangeably, but they are slightly different.

A cast resin transformer (CRT) is actually a subcategory of dry type transformers. In CRTs, both windings are completely cast in epoxy resin. This provides excellent protection against humidity, salt, and chemical pollution—ideal for outdoor installations or industrial sites with poor air quality.

Meanwhile, VPI models use varnish impregnation, offering good insulation at a lower cost. The right choice depends on your budget, environmental conditions, and safety requirements.

How to Select the Right Dry Type Transformer

Choosing the right transformer for your project isn’t just about capacity — it’s about strategic planning and lifecycle value. Here’s what engineers and procurement specialists should consider:

- Power Rating and Load Type – Match the kVA rating to your system’s real demands, considering future expansion.

- Ambient Conditions – Select suitable insulation classes for humid or corrosive environments.

- Efficiency Class – Look for transformers meeting DOE or IEC 60076 efficiency standards.

- Cooling Type – Decide between natural air cooling (AN) or forced air cooling (AF) systems.

- Customization Options – Ask suppliers about enclosures, tap changers, and protection levels like IP21 or IP54.

Pro tip: Always request a technical data sheet before ordering to ensure compatibility with existing switchgear and power distribution equipment.

Installation and Maintenance Tips

Even though dry type transformers demand minimal servicing, proper installation ensures long operational life.

Installation tips:

- Always ensure adequate airflow or fan-assisted cooling.

- Avoid exposure to direct sunlight, dust, or corrosive environments.

- Ground the transformer properly to prevent electrical hazards.

Maintenance recommendations:

- Perform periodic visual inspection for dust accumulation or corrosion.

- Verify temperature sensors and protection relays regularly.

- Use thermal scanning during scheduled shutdowns.

For critical systems, establishing a predictive maintenance schedule can prevent unexpected downtime—especially in facilities with continuous 24/7 operations.

To sum up, dry type transformers deliver a powerful combination of safety, performance, and sustainability — exactly what modern facilities demand. Whether you’re an electrical engineer designing a new power distribution system or a procurement manager sourcing eco-compliant equipment, these transformers represent a smart long-term investment.

They might not use oil, but they keep industries running smoothly. If you’re planning your next infrastructure or retrofit project, reach out for a customized dry type transformer solution today — and power your future with safety and efficiency.

FAQ

What are the main advantages of a dry type transformer?

They are safe, eco-friendly, require minimal maintenance, and perform well in high-traffic or enclosed environments.

Can dry type transformers be used outdoors?

Yes. With suitable enclosures (like IP23 or stainless-steel housings), they function reliably in outdoor or humid conditions.

What is the life expectancy of a dry type transformer?

Typically between 20–30 years with proper installation and maintenance.

What are common industries using dry type transformers?

Hospitals, commercial buildings, renewable energy, manufacturing, and offshore platforms.

How can I purchase or request a quote?

Contact a verified dry type transformer manufacturer or distributor. Provide your voltage, kVA rating, and cooling class to receive a tailored quotation.

Table of Contents

Ready to explore your options?

Contact us today for a custom dry type transformers quotation — because the right transformer doesn’t just move power, it powers your entire business forward.