If you’re searching for a dry type transformer supplier, you already know how important it is to find a partner who delivers quality, reliability, and tailored solutions. Whether you’re managing a commercial facility, data center, or industrial plant, choosing the right transformer affects safety, efficiency, and long-term performance. In this guide, you’ll discover what sets dry-type transformers apart, key factors to consider when selecting a supplier, and why a trusted name like Kampa can meet your exact needs with customizable, high-quality products. Let’s cut through the noise and help you make the best choice for 2026 and beyond.

What Is a Dry-Type Transformer and Why Choose It Over Oil-Filled Alternatives?

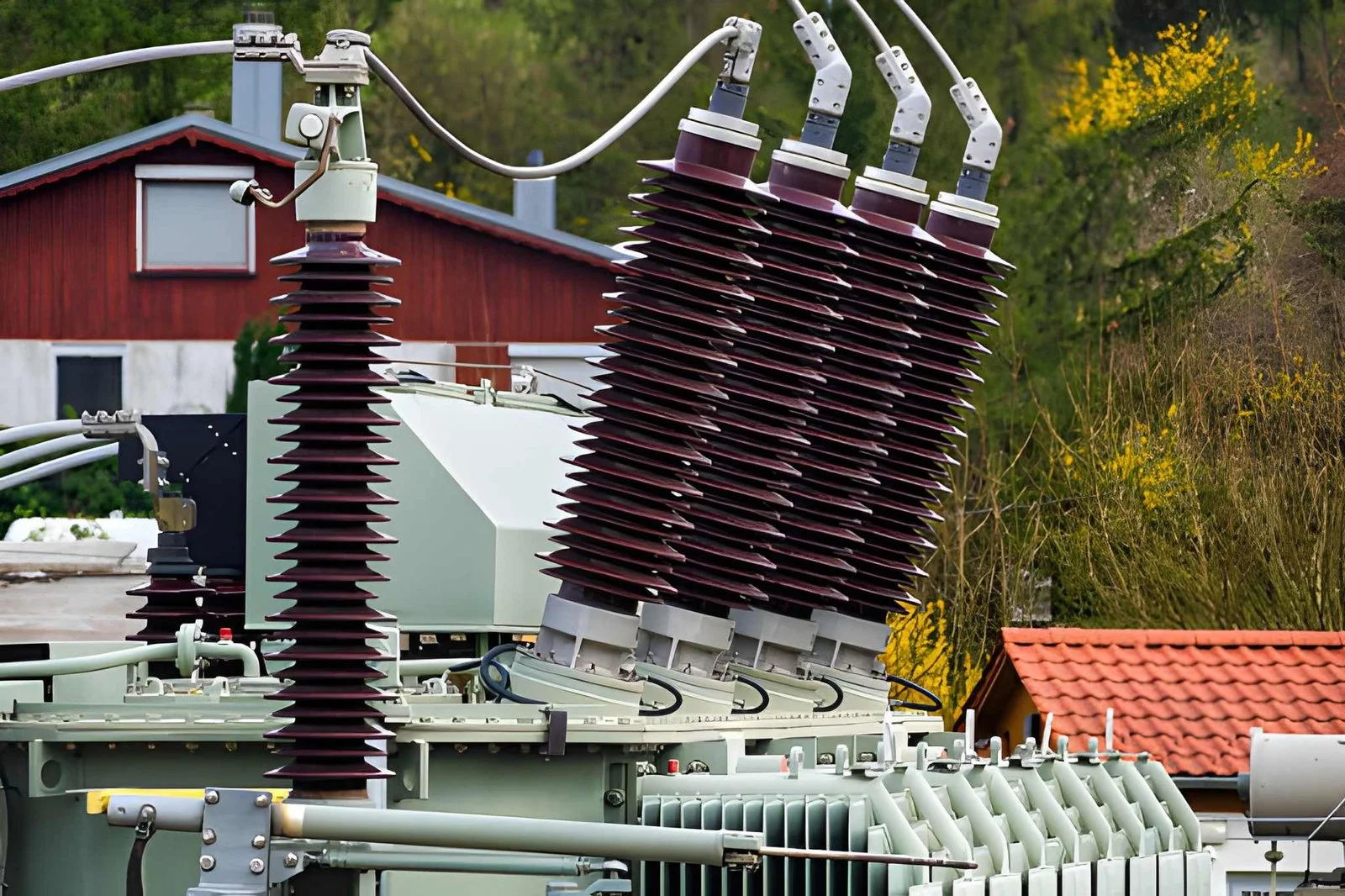

A dry-type transformer uses air rather than liquid to cool and insulate its components. Unlike oil-filled transformers that rely on mineral oil or other fluids for insulation and heat dissipation, dry-type transformers use air cooling, making them safer and more environmentally friendly. The core and windings are enclosed in epoxy resin or cast resin, ensuring no liquid leaks and reducing fire risks.

Dry-Type vs. Oil-Filled Transformer Comparison

| Feature | Dry-Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Method | Air-cooled (no liquid) | Oil-cooled (liquid insulation) |

| Safety | Fire-resistant, low fire risk | Higher fire hazard due to oil |

| Installation | Indoor-friendly, flexible | Requires outdoor or ventilated space |

| Maintenance | Low maintenance | Requires regular oil checks and replacement |

| Efficiency | Slightly lower, modern designs improve this | High efficiency, oil helps cooling |

| Cost | Generally lower initial cost, lower risk costs | Higher initial and maintenance costs |

Common Applications of Dry-Type Transformers

Dry-type transformers are widely used where safety, reliability, and minimal maintenance are critical. Typical applications include:

- Commercial buildings: Offices and shopping centers benefiting from fire-safe transformers

- Data centers: Where overheating and downtime must be minimized

- Hospitals: For clean, non-toxic, and safe electrical distribution

- Renewable energy projects: Solar and wind power systems requiring robust, maintenance-free transformers

- Industrial plants: Machinery and equipment needing reliable power without fire risks

Choosing a dry-type transformer supplier that understands these applications ensures you get the right product tailored to your needs.

Main Types of Dry-Type Transformers

Dry-type transformers come in several types, each suited to different needs and environments. Here’s a quick breakdown:

| Transformer Type | Key Features | Advantages | Ideal Uses |

|---|---|---|---|

| Cast Resin Transformer | Windings sealed in epoxy resin | High moisture resistance, strong mechanical durability | Commercial buildings, hospitals, and industrial plants |

| Vacuum Pressure Impregnated (VPI) | Windings impregnated with resin under vacuum | Excellent durability and insulation, ideal for harsh conditions | Outdoor, renewable energy, and heavy industrial setups |

| Vacuum Pressure Encapsulated (VPE) | Enhanced sealing with vacuum encapsulation | Superior protection against dust, moisture, and corrosives | Demanding environments with extreme conditions |

| Open Wound Transformer | Traditional exposed coil design | Cost-effective, easy repair | Standard commercial and light industrial applications |

At Kampa, we provide a versatile range of dry-type transformers to cover these types, ensuring we meet a broad spectrum of project demands. Whether you need a high-performance VPI dry type transformer or a reliable cast resin transformer, our selection supports your exact requirements.

For more on these types and their specific applications, explore our detailed resource on dry-type transformer types and their applications.

Key Factors to Consider When Selecting a Dry-Type Transformer Supplier

Choosing the right dry type transformer supplier is crucial for getting a reliable, efficient product that fits your needs. Here are the main factors to keep in mind:

- Quality Certifications and Standards: Look for suppliers with recognized certifications like IEC, UL, CE, and ISO 9001. These prove the transformers meet international safety and performance standards.

- Manufacturing Expertise and Capacity: A supplier with strong manufacturing experience and sufficient production capacity ensures consistent quality and timely delivery, especially for large or customized orders.

- Material Quality: High-grade materials — like copper or aluminum windings combined with premium insulation — directly affect transformer durability and efficiency.

- Energy Efficiency and Low-Loss Design: Opt for energy efficient transformers that reduce operational costs over time. Low-loss designs help save power and improve overall system performance.

- Warranty and Support: Reliable warranty terms along with solid after-sales support and technical assistance make maintenance easier and reduce downtime risks.

- Lead Times and Shipping: Fast, dependable lead times with global shipping options ensure your project schedule stays on track. Responsive customer service is key for smooth communication.

By focusing on these points, you can confidently select a trusted dry type power transformer supplier that offers quality, efficiency, and support tailored to your needs. For example, Kampa Electric combines certifications, advanced manufacturing, and excellent customer care to meet diverse project requirements worldwide.

How to Evaluate and Choose the Right Dry Type Transformer Supplier

Choosing the right dry type transformer supplier can make a big difference in your project’s success. Here’s a simple step-by-step guide to help you decide smartly:

Step-by-Step Buying Guide

| Step | What to Do |

|---|---|

| 1. Define Your Needs | Identify key specs: kVA rating, voltage level, phase type (single or three-phase). |

| 2. Request Quotes | Get detailed price offers from multiple suppliers to compare. |

| 3. Review Case Studies | Look for examples of similar projects the supplier has completed successfully. |

| 4. Factory Audit & Test Reports | Ask for audit reports and performance tests to verify quality and compliance. |

Red Flags to Watch For

- No valid certifications like IEC, UL, or ISO 9001.

- Poor customer reviews or lack of references.

- Vague or incomplete technical specifications.

- No warranty or weak after-sales support.

Balancing Cost and Long-Term Value

- Don’t just go for the lowest price—consider energy efficiency, durability, and warranty terms.

- A slightly higher upfront cost for an energy efficient transformer often lowers your operating expenses over time.

- Check supplier responsiveness and delivery times to avoid project delays.

For detailed advice on selecting dry type transformers tailored to your needs, explore Kampa’s guide on how to select the right dry-type transformers for your project to make an informed choice.

Dry-Type Transformer Pricing Guide

Pricing for dry-type transformers depends on several key factors: the capacity (measured in kVA), voltage class, the choice of materials (like copper or aluminum windings), and any required customization. For example, larger capacity transformers or those designed for medium voltage will naturally cost more than smaller, low voltage dry transformers. Custom features like special enclosures, K-factor ratings, or enhanced insulation also impact the price.

Here’s a rough idea of average price ranges for common dry-type transformer ratings:

- Small capacity (up to 75 kVA): $1,000–$3,000

- Medium capacity (75–500 kVA): $3,000–$10,000

- Large capacity (over 500 kVA): $10,000 and up

Investing in an energy-efficient transformer can reduce operational expenses significantly over time by lowering energy losses and heat generation. This makes the initial price a better long-term value.

At Kampa, we maintain a transparent pricing approach with clear quotes and no hidden fees. We balance competitive pricing with quality, ensuring you get reliable dry-type power transformers without surprises. For a detailed look at our pricing and options, check out our dry-type transformers for industrial applications to find the right fit for your project’s needs.

Customization Options for Dry-Type Transformers

When it comes to dry-type transformers, one size rarely fits all. Customization is key to meeting the exact needs of your project. Here’s what can be tailored to fit your unique requirements:

| Customization Feature | Options Available | Benefits |

|---|---|---|

| Voltage Ratings | Special primary and secondary voltages | Perfect match for non-standard power systems |

| Enclosures (IP Ratings) | IP21, IP44, IP54, and higher | Protection against dust, moisture, and harsh environments |

| Cooling Methods | Natural Air Cooling (AN), Forced Air Cooling (AF) | Enhanced efficiency and longer lifespan |

| K-Factor Ratings | Designed for non-linear loads | Superior heat resistance and durability |

Custom designs help improve operational efficiency and ensure compliance with your system specs, especially in complex settings like data centers or renewable energy projects.

At Kampa, we specialize in OEM and ODM customization for dry-type transformers. Our expertise ensures each transformer matches your exact electrical, mechanical, and environmental demands, without unnecessary cost or delays. From cast resin transformers to VPI dry type transformers, we deliver tailored, energy-efficient solutions that stand the test of time.

Explore how our precise transformer customization can fit your project needs while optimizing performance and reliability.

For more on advanced designs and applications, see our detailed overview of dry-type transformer core technology and design.

Why Kampa Is Your Trusted Dry-Type Transformer Supplier

Kampa stands out as a reliable dry-type transformer supplier thanks to its advanced manufacturing processes and strict quality controls. We offer a wide range of dry-type power transformers — including cast resin, VPI, and open wound types — designed to meet diverse needs across industries. Our transformers are known for their energy efficiency, durability, and compliance with international standards like IEC and UL, ensuring you get consistent, high-performance products.

What makes Kampa a preferred partner? It’s our combination of competitive pricing, fast delivery, and customer-focused support that helps businesses simplify their buying experience. From industrial plants to data centers, many customers have successfully integrated our transformers into their power systems, benefiting from low maintenance and reliable operation.

If you’re looking for a trusted dry-type transformer supplier with expertise in customization, quality, and service, Kampa is ready to assist. Contact us today for a personalized quote or consultation tailored to your project requirements.

Explore more about our transformer offerings, including our oil-immersed distribution transformers, to find the best solution for your needs.

Maintenance and Installation Best Practices

Keeping your dry type transformer in top shape is easier than you might think. Simple maintenance routines can extend the life of your transformer and help avoid costly downtime. Regularly check for dust and dirt buildup, ensure proper ventilation around the unit, and inspect insulation and connections for signs of wear or damage. Periodic cleaning with dry, non-abrasive tools and verifying tightness of electrical connections are essential steps.

When it comes to installation, following the right guidelines is key for both performance and safety. Make sure the transformer is mounted on a level, non-combustible surface in a well-ventilated indoor area. Maintain clearance distances as specified to allow free airflow and heat dissipation. Grounding the unit correctly reduces electrical risks and improves reliability. Also, avoid placing dry type transformers near flammable materials or excessive moisture.

For professional-grade dry type power transformers, consider trusted suppliers like Kampa who provide detailed installation manuals and offer technical support. Their products include safety features aligned with international standards and are designed for easy setup.

Proper maintenance and installation not only ensure safety and efficiency but also protect your investment in an energy-efficient transformer over the long term.

For specific installation solutions, you can also explore Kampa’s offerings for industrial power distribution here.