If you’re involved in power distribution or electrical system design, you’ve probably heard about dry type distribution transformers—but what exactly are they, and why are they becoming the go-to choice for modern installations? Unlike traditional oil-filled transformers, dry type transformers use air for cooling and solid insulation, making them a safer, eco-friendly solution ideal for indoor and fire-sensitive environments. In this post, you’ll get a clear, concise explanation of what a dry type distribution transformer is, how it works, and why trusted suppliers like Kampa are leading the way with high-quality, customized options that meet today’s demanding standards. Let’s break it down.

What Is a Dry Type Distribution Transformer?

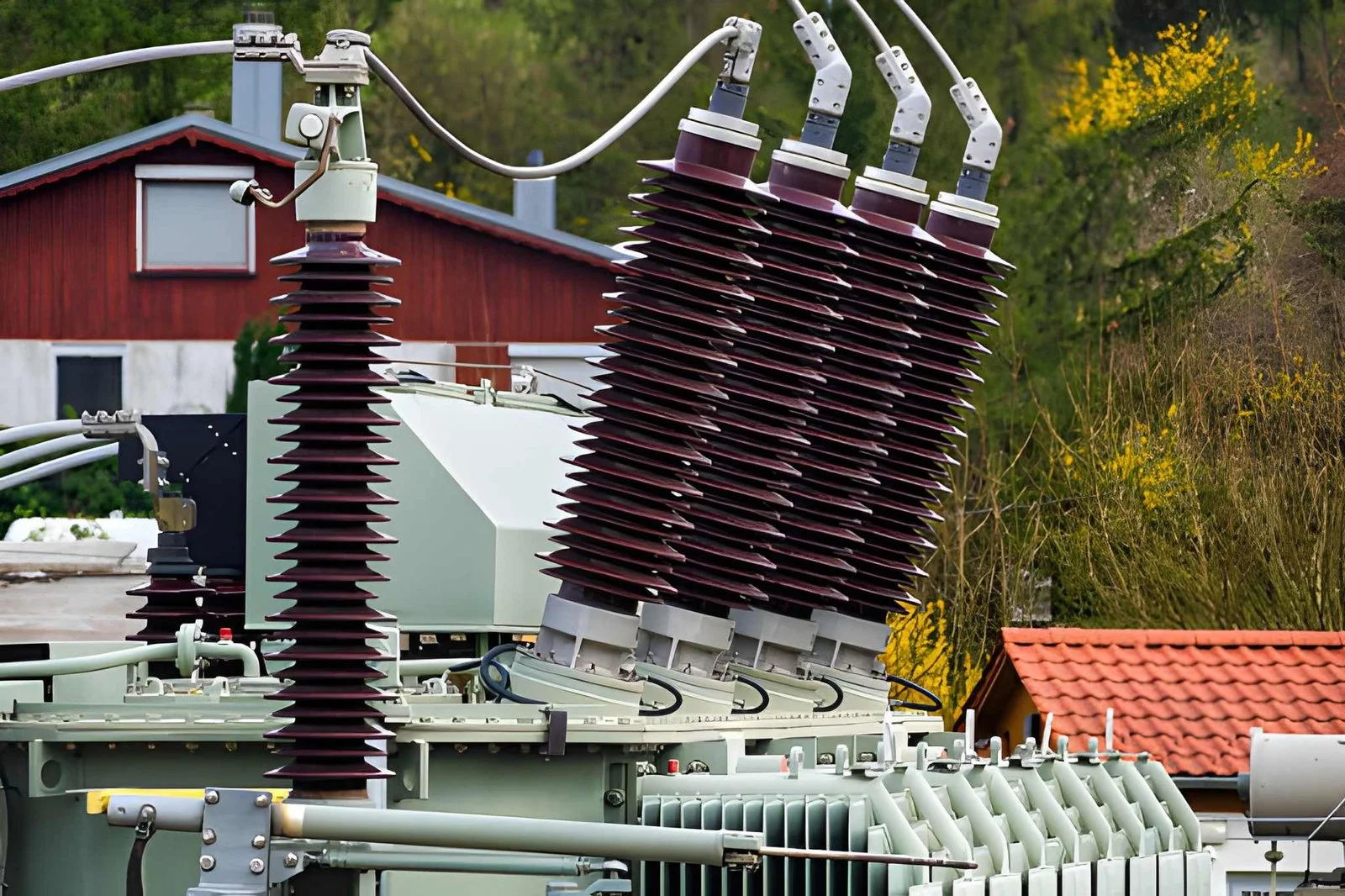

A dry type distribution transformer is an electrical device designed to step down medium voltage to low voltage, making power safe and usable for end consumers. Unlike oil-filled transformers, dry type transformers use air or gas for cooling and rely on solid insulation materials—such as epoxy resin—instead of liquid insulation like oil or other fluids. This makes them inherently safer and more environmentally friendly.

Role in Power Distribution

Dry type transformers are key players in power distribution systems, especially where safety, indoor installation, or environmental concerns matter. Their purpose is simple yet vital: converting medium voltage electricity from the grid down to a lower voltage, suitable for commercial, industrial, or residential use.

Key Components

- Core: Usually made of laminated silicon steel, it provides the magnetic path.

- Windings: Includes both high-voltage and low-voltage windings, wrapped around the core to transfer electrical energy via electromagnetic induction.

- Enclosure: Protects internal components from physical damage, dust, and moisture; often designed to facilitate air cooling.

- Cooling System: Uses natural air ventilation or forced air to dissipate heat generated during operation.

Dry type transformers are widely preferred for their safety, clean operation, and flexibility in installation environments, making them an essential part of modern electrical networks.

How Dry Type Distribution Transformers Work

Dry type distribution transformers operate on the basic principle of electromagnetic induction. When alternating current flows through the transformer’s primary winding, it creates a magnetic field in the core. This changing magnetic field induces voltage in the secondary winding, allowing the transformer to step voltage levels up or down as needed, typically from medium to low voltage for safe end-use.

Cooling in dry type transformers is managed without oil. Instead, they rely on air and solid insulation to prevent overheating. There are two main cooling methods:

- Natural Air Ventilation (AN): Air circulates freely around the transformer, dissipating heat naturally through convection. This is common in smaller units or those with lower loads.

- Forced Air Ventilation (AF): Fans or blowers actively push air over the transformer surfaces, improving cooling efficiency. This method suits larger transformers or those in environments where heat buildup is a concern.

Insulation plays a crucial role in managing temperature rise and ensuring the transformer’s longevity. Dry type transformers use solid insulation materials like epoxy resins or vacuum pressure impregnated (VPI) coatings that withstand heat better and reduce risks of moisture damage. These materials maintain electrical integrity and keep temperature rise within safe limits, which is essential for reliable performance.

For a deeper dive into how the cooling and insulation systems work inside, check out this detailed explanation on how dry type transformers really work.

Types of Dry Type Distribution Transformers

Dry type transformers come mainly in two types: Vacuum Pressure Impregnated (VPI) and Cast Resin Transformers (CRT). Each has distinct features and ideal uses depending on the application and environment.

| Transformer Type | Construction | Key Features | Typical Applications |

|---|---|---|---|

| Vacuum Pressure Impregnated (VPI) | Open-wound coils impregnated with insulating varnish under vacuum pressure | Good thermal performance, lightweight, suitable for indoor/outdoor use | General industrial, commercial buildings, moderate environment |

| Cast Resin Transformer (CRT) | Epoxy resin encapsulated coils (fully sealed) | Excellent moisture and dust resistance, high safety, fire-retardant | Harsh environments, hospitals, data centers, and indoor areas needing high fire safety |

VPI transformers use a varnish impregnation process to seal the coils while maintaining some ventilation, allowing good cooling and flexibility. In contrast, cast resin transformers encase the windings in epoxy resin, creating a robust barrier against moisture and contaminants, making them ideal for wet or chemically aggressive conditions.

For a deeper dive into the differences and applications of these dry type transformer types, check out our detailed guide on dry type transformer types and their applications. You can also explore the comparison between dry type and cast resin transformers to understand which suits your needs best.

By choosing the right dry type transformer based on these types, you balance performance, safety, and cost effectively.

Dry Type vs. Oil-Filled Transformers: Key Differences

When deciding between dry type transformers and oil-filled transformers, the main differences come down to cooling, insulation, safety, maintenance, efficiency, and cost.

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Method | Air or gas cooling with solid insulation | Oil immersion cooling with liquid insulation |

| Insulation | Solid epoxy resin or varnished windings | Mineral or synthetic oil insulation |

| Fire Safety | Fire-safe, no oil spill risk | Risk of fire or oil leaks |

| Maintenance | Low maintenance, no oil checks | Requires regular oil testing & servicing |

| Cost | Higher initial cost | Generally lower upfront cost |

| Efficiency | Slightly lower efficiency at high loads | Often better cooling for large loads |

| Installation | Ideal for indoor and sensitive areas | Mainly outdoor or specially designed indoor rooms |

| Environmental Impact | Eco-friendly, recyclable materials | Oil disposal and leak concerns |

When to Choose Dry Type Transformers

- Fire risk is critical—dry type’s air cooling eliminates oil fire hazards.

- Indoor or noise-sensitive locations, like hospitals or schools.

- Low maintenance preference or limited space for oil handling.

- When environmental concerns are a priority.

- In applications requiring easy installation and better safety compliance.

For more detailed insights on selecting the right transformer type, exploring a trustworthy dry type transformer supplier can streamline the decision process with tailored advice.

Compared to oil-filled models, dry type transformers deliver safer, cleaner power distribution with less hassle, especially in urban or high-rise buildings where fire safety and low maintenance are top priorities.

Advantages of Dry Type Distribution Transformers

Dry type distribution transformers offer several clear benefits that make them a preferred choice for many applications. One of their biggest advantages is superior fire safety. Since they use air or gas for cooling and solid insulation instead of oil, there’s no risk of oil leaks or spills that could cause fires or environmental hazards. This makes them much safer in indoor settings or areas where fire risk must be minimized.

They are also environmentally friendly and recyclable, as they avoid the use of hazardous oils and toxic liquids. This aligns well with growing global demands for greener industrial solutions. Maintenance requirements are low, since there’s no oil monitoring or replacement, leading to reduced downtime and operational costs. Plus, their long service life ensures reliable performance over many years.

Dry type transformers are ideal for indoor installations and noise-sensitive environments. Their design often results in quieter operation compared to some oil-filled transformers, making them suitable for commercial buildings, hospitals, and schools. Additionally, they demonstrate high resilience to moisture, dust, and short circuits, thanks to robust insulation materials commonly used in models like cast resin transformers.

For a detailed look at a quality cast resin transformer and its safety features, you can explore the offerings of a trusted dry type transformer supplier such as Kampa with their range of reliable products designed for smart power solutions. Learn more about their approach to dry type transformer safety and smart power solutions.

Disadvantages and Limitations of Dry Type Distribution Transformers

Dry type transformers generally come with a higher initial cost compared to oil-filled models. This upfront investment can be significant, especially when selecting cast resin or VPI (Vacuum Pressure Impregnated) transformers for specialized applications. Additionally, dry type transformers tend to have a limited capacity for very high-power needs, making them less suitable for heavy industrial loads where oil-filled transformers dominate.

Another challenge is that some dry type designs may produce more noise and heat during operation. Without liquid cooling, managing temperature rise relies heavily on air circulation, which can lead to louder and warmer performance in enclosed or poorly ventilated spaces.

To address these issues, proper enclosure design and effective ventilation systems are essential. Using forced air cooling or installing transformers in well-ventilated areas helps reduce overheating and noise. These mitigation strategies improve the transformer’s lifespan and efficiency, ensuring the best performance from your dry type transformer.

For high-demand or sensitive environments, consider these limitations alongside the benefits when choosing a dry type transformer or consulting with a reliable transformer supplier. This ensures you get the ideal balance between safety, cost, and operational needs.

Common Applications of Dry Type Distribution Transformers

Dry type distribution transformers are widely used across various sectors due to their safety, reliability, and eco-friendly features. They are a top choice for commercial buildings such as offices, shopping malls, and hotels, where low maintenance and fire-safe operation are critical.

In healthcare and educational facilities, including hospitals and schools, these transformers provide dependable power with minimal risk of fire or oil leaks, making them ideal for sensitive environments.

They also perform well in industrial sites like chemical plants, data centers, and renewable energy installations. Here, resistance to moisture, dust, and short circuits ensures continuous operation even under demanding conditions.

Finally, dry type transformers are preferred in urban and high-rise buildings where fire safety regulations are strict. Their solid insulation and air cooling significantly reduce fire hazards, making them suitable for indoor distribution in densely populated areas.

For projects demanding tailored medium and high voltage solutions, partnering with a trusted supplier that offers customized dry type transformers can make a significant difference in performance and compliance. Explore reliable options in the medium and high voltage power solutions range to find the best fit for your application.

Key Specifications to Consider

When choosing a dry type distribution transformer, several key specs can make all the difference in performance and suitability:

| Specification | What to Look For | Why It Matters |

|---|---|---|

| Voltage Ratings | Match system voltage (e.g., 11kV/415V) | Ensures compatibility with your power setup |

| kVA Capacity | Based on load requirement | Determines transformer size and efficiency |

| Efficiency Standards | Compliance with DOE 2016 or similar | Saves energy and reduces running costs |

| Insulation Class | Common classes: Class H (180°C), Class F (155°C) | Affects temperature resistance and lifespan |

| Temperature Rise | Limits (e.g., 115°C max) | Keeps transformer cool and reliable |

| Impedance | Percentage value (typically 4-6%) | Influences voltage regulation and fault current |

| Enclosure Types | IP ratings (IP23, IP54 etc.) | Protection against dust, water, and environmental factors |

| Noise Levels | Measured in dB, lower is better | Important for indoor or noise-sensitive areas |

| Winding Materials | Copper vs. Aluminum | Copper offers better conductivity; aluminum reduces cost and weight |

Each of these specs impacts how well the dry type transformer fits your environment and load demands. For example, if you need a quiet indoor distribution transformer, checking noise ratings and enclosure types is crucial. Similarly, high insulation class and temperature rise ratings mean the transformer can handle demanding conditions without breakdown.

For in-depth specs and options, exploring suppliers like Kampa’s range of dry-type power transformers provides detailed product info tailored to various industries and applications.

Installation, Maintenance, and Best Practices for Dry Type Distribution Transformers

Proper installation is key to getting the most out of your dry type distribution transformer. Start by ensuring good ventilation around the unit to prevent overheating. Keep enough clearance on all sides—usually at least a few inches—to allow natural air flow and easy access for maintenance. Mount the transformer on a sturdy, level platform that can support its weight and reduce vibrations.

Routine maintenance is straightforward but important. Regularly check for dust, dirt, and moisture buildup on the enclosure and cooling vents, as these can reduce efficiency and cause overheating. Inspect connections and wiring for any signs of wear or loose fittings. Monitoring temperature rise during operation helps catch overheating issues early. If your transformer uses forced air cooling (AF), make sure fans and blowers are clean and operational.

Here are some quick tips to extend your dry type transformer’s lifespan:

- Keep the installation site clean and dry to minimize corrosion and insulation degradation.

- Avoid overloading; stay within the transformer’s rated capacity.

- Schedule periodic insulation resistance tests to detect early signs of degradation.

- Use quality replacement parts and professional service when needed.

- Follow the manufacturer’s guidelines for temperature limits and operating conditions.

For specific installation and maintenance guidance, it’s always wise to consult trusted transformer suppliers like Kampa, who provide detailed resources and support tailored to your needs. Check out reliable transformer options and solutions to help maintain peak performance in your power distribution setup.

By following these best practices, you can ensure your dry type transformer remains efficient, safe, and long-lasting in any industrial or commercial installation.

Pricing, Customization, and Choosing a Supplier

When it comes to dry type distribution transformers, price depends on several key factors:

| Factor | Impact on Price |

|---|---|

| Transformer size | Larger capacity means higher cost |

| Type | Cast resin (CRT) tends to cost more than VPI due to materials |

| Features | Special enclosures, cooling methods, or insulation classes add cost |

| Customization | Tailored designs for unique site needs affect pricing |

Customizing transformers can greatly improve performance and fit for specific projects—whether that’s unusual voltage ratings, special enclosures for harsh environments, or enhanced cooling options. Working with a supplier who offers customization ensures you get the exact solution, avoiding overspending on unnecessary specs.

Choosing the right supplier is crucial. For example, Kampa provides high-quality dry type transformers that meet international quality standards. Their products come with reliable delivery schedules and customizable options tailored to your power distribution needs. This makes Kampa a trusted partner for businesses worldwide looking for fire-safe, low maintenance, and eco-friendly transformers.

For tailored solutions and reliable supply of dry type transformers, you can check out Kampa’s comprehensive selection and expert services here.

Prioritizing quality, customization, and supplier reputation helps secure the best value for your investment in dry type transformers.