Transformers are the heart of power distribution systems, quietly working behind the scenes to ensure smooth and safe energy flow. But when it comes to choosing between a dry type transformer and an oil-immersed transformer, many engineers and procurement professionals pause. Which is safer? Which performs better in demanding environments? And which one gives you the best lifecycle cost?

If you’re exploring options for an upcoming industrial project — or comparing transformer types for reliability and efficiency — this guide breaks everything down clearly, without buzzwords or fluff.

What Is a Dry Type Transformer?

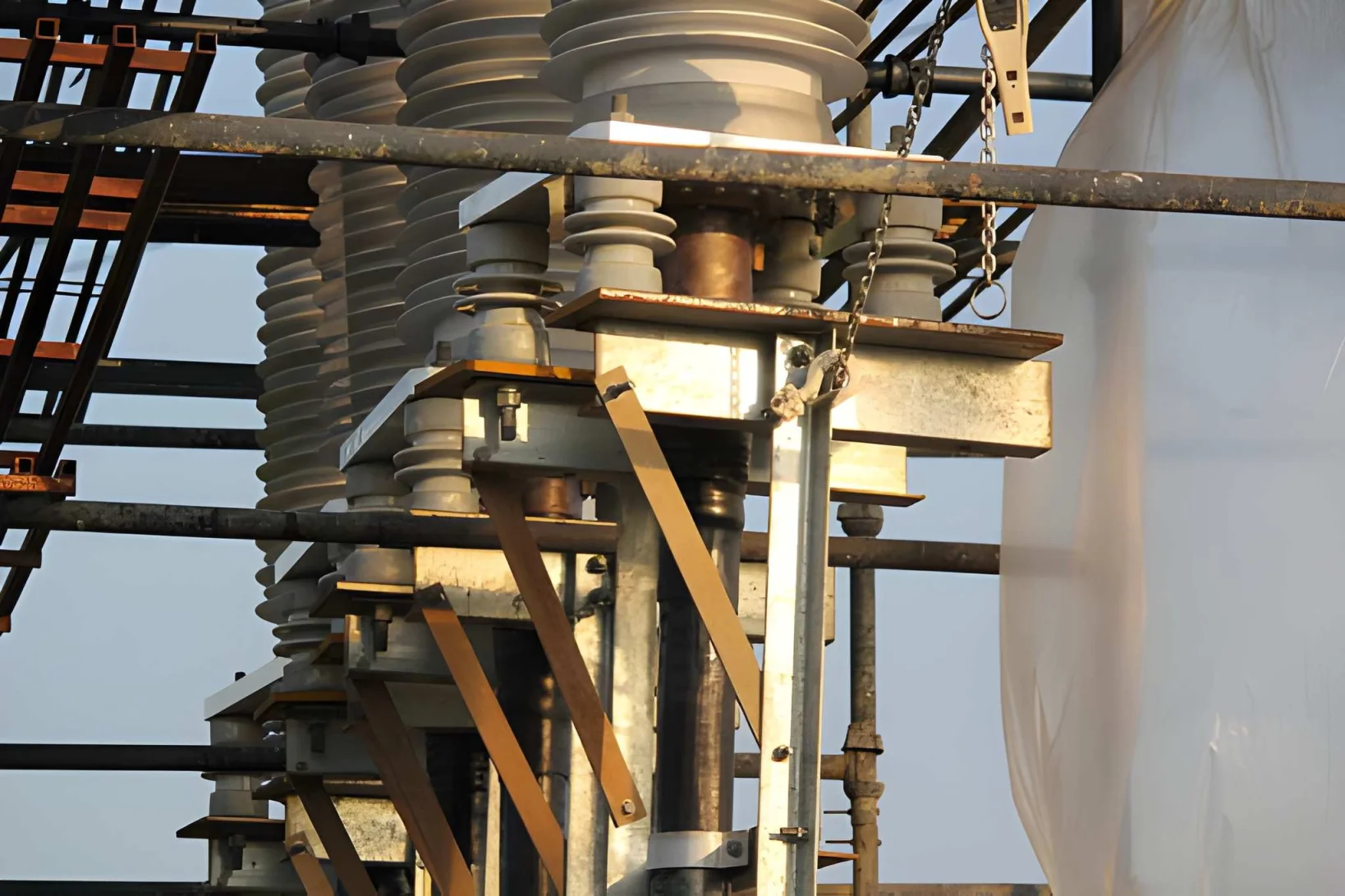

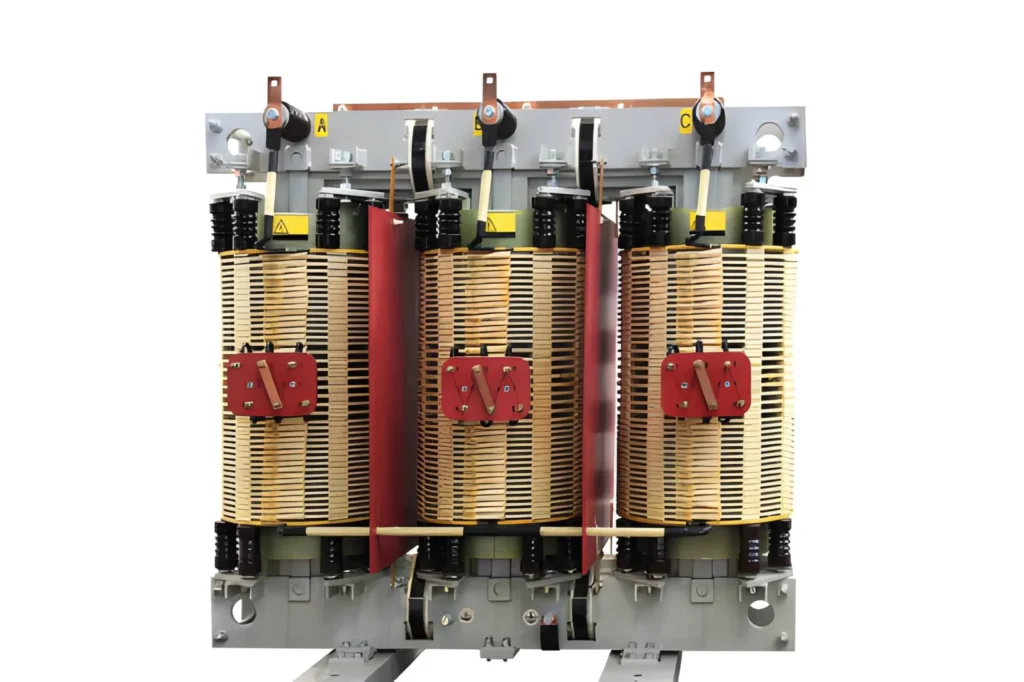

A dry type transformer is an electrical transformer that uses air instead of liquid (oil) as its cooling medium. Its windings and magnetic core are kept within a vacuum-sealed epoxy resin or cast resin enclosure, allowing effective cooling through natural air circulation or forced air ventilation.

This construction eliminates the need for oil, making dry type transformers safer and more environmentally friendly. They are especially favored in commercial buildings, data centers, hospitals, underground substations, and renewable energy systems.

Key characteristics of dry type transformers include:

- Cooling method: Air-cooled (natural or forced).

- Insulation: Epoxy resin or cast resin.

- Safety: Non-flammable and requires minimal maintenance.

- Installation: Suitable for indoor and confined spaces.

Dry Type Transformer vs. Oil-Immersed Transformer Overview

| Feature | Dry Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Cooling Medium | Air / Cast resin | Mineral oil or silicone oil |

| Safety | Fire-resistant | Requires fire protection measures |

| Environmental Impact | Eco-friendly | Oil leakage risk |

| Installation | Indoor or harsh sites | Outdoor only (mostly) |

| Maintenance | Low | Periodic oil checks and filtration |

| Efficiency | Slightly lower | Higher efficiency under heavy load |

| Cost | Higher initial investment | Lower upfront cost |

How Dry Type Transformers Operate

Just like any other transformer, a dry type unit works on the principle of electromagnetic induction. When alternating current flows through the primary winding, it produces a magnetic field that induces voltage in the secondary winding.

The significant difference lies in the cooling mechanism. Instead of relying on circulating oil to dissipate heat, dry type transformers use air ducts or fans to maintain optimal temperature. The resin-encapsulated coils protect against moisture, dust, and corrosion — critical for operations in challenging environments.

In modern power infrastructure, dry type designs also feature smart sensors and temperature monitoring systems, helping maintenance teams remotely track performance and prevent failure.

Main Differences Between Dry Type and Oil-Immersed Transformers

While both transform electrical energy efficiently, they serve different application niches. Let’s take a closer look at their differences in performance and practicality.

1. Safety and Fire Risk

Safety is often the top concern in industrial power distribution. Unlike oil-filled transformers, dry type units don’t contain flammable materials, drastically reducing fire risk. This makes them ideal for high-rise complexes, underground facilities, and public infrastructure where fire safety is critical.

Oil-immersed transformers, on the other hand, require extensive safety systems such as fire suppression, oil containment basins, and leak monitoring sensors.

2. Cooling and Maintenance

In oil-immersed transformers, oil acts both as coolant and dielectric medium. Over time, the oil’s quality deteriorates due to oxidation, necessitating filtration, replacement, and dissolved gas analysis.

Dry type transformers, however, rely on clean air circulation or forced ventilation fans for cooling. There’s no need for oil checks, making them almost maintenance-free — a major advantage for projects that prioritize uptime and low operating costs.

3. Efficiency and Load Capacity

Oil-immersed transformers generally achieve higher efficiency levels under heavy loads because of oil’s better heat dissipation properties. They’re widely used in utility grids, industrial plants, and outdoor substations where efficiency and long operation hours matter more than installation constraints.

Dry type units, while slightly less efficient (by 1–2%), compensate with longer insulation life and zero contamination risk.

4. Installation and Space Requirements

If space is limited, dry type transformers are often the smarter choice. Since they don’t need fire barriers or oil containment, they can be installed closer to the load center, saving cable costs.

Oil-immersed transformers require dedicated outdoor enclosures, ventilation, and protection systems, which increase total project footprint.

5. Environmental and Regulatory Compliance

As environmental regulations tighten worldwide, many industries are shifting toward eco-friendly dry type transformers. The absence of oil eliminates leakage risks, soil contamination, and complex hazardous waste disposal.

Oil-immersed designs can still comply with modern standards, but they require premium eco-fluids or advanced containment systems to meet environmental requirements.

Ready to explore your options?

Contact us today for a custom Dry Type Transformer vs. Oil-Immersed Transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.

Application Scenarios and Industry Use

The best choice depends on your operating environment and project goals.

| Application Area | Recommended Transformer Type | Reason |

|---|---|---|

| Hospitals and Commercial Buildings | Dry type transformer | Fire-safe and easy indoor installation |

| Data Centers | Dry type transformer | Low maintenance and minimal downtime |

| Heavy Industry | Oil-immersed transformer | Handles high overloads efficiently |

| Renewable Energy Farms | Dry type transformer | Resistant to environmental moisture |

| Rural Power Distribution | Oil-immersed transformer | Cost-effective for large outdoor setups |

When consulting with transformer manufacturers, discuss your load profile, installation site, voltage class, and expected service life to determine the ideal model.

If you want expert guidance or custom solutions, feel free to send us an inquiry or quote request — our technical team can recommend the most reliable transformer for your project.

Pros and Cons Summary

| Aspect | Dry Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Fire Safety | Excellent | Moderate |

| Environmental Impact | Minimal | Moderate to high |

| Maintenance | Low | High |

| Installation Flexibility | High | Limited |

| Cost | Moderate to high | Lower |

| Noise Level | Low | Moderate |

| Lifespan | 20–25 years | 25–30 years (with oil care) |

Each design brings unique strengths, so the better choice depends on your project’s priorities — not a one-size-fits-all answer.

Why Industries Are Moving Toward Dry Type Transformers

Over the last decade, B2B energy procurement trends have shifted rapidly toward dry type solutions. The reasons are clear:

- Safety-first regulations: Building codes are increasingly favoring fire-safe electrical infrastructure.

- Sustainability initiatives: Green manufacturing and environmental compliance drive the adoption of oil-free systems.

- Technological progress: Cast resin insulation and forced air systems have dramatically improved thermal performance.

- Ease of installation: Reduced infrastructure and maintenance costs make dry type units ideal for fast-paced projects.

For EPC contractors, electrical system designers, and industrial buyers, this translates to lower lifecycle costs, faster deployment, and improved safety certification compliance.

Buying Tips for B2B Buyers

When sourcing dry type transformers for industrial or commercial applications, consider these key buying factors:

- Voltage and Power Rating: Match your load demand and grid specification.

- Insulation Type: Epoxy cast resin or VPI (Vacuum Pressure Impregnation) options offer differing moisture protection.

- Cooling Method: Natural air (AN) or forced air (AF) cooling depending on usage intensity.

- Thermal Class: Typically Class F (155°C) or Class H (180°C).

- Compliance Standards: Look for IEC 60076, IEEE C57, or local utility certifications.

- Manufacturer Warranty and Support: Ensure long-term technical assistance and spare part availability.

Partnering with a reputable transformer manufacturer can optimize both performance and project cost control.

In choosing between a dry type transformer and an oil-immersed transformer, there’s no universal winner. It all depends on where you install it, what your safety standards demand, and how much maintenance your operation can tolerate.

For modern, eco-conscious facilities prioritizing safety, dry type transformers deliver unmatched reliability and peace of mind. On the other hand, for high-capacity outdoor settings, oil-immersed transformers remain a strong and cost-efficient option.

If you’re planning an industrial upgrade or power distribution project, reach out to our engineering team for a tailored dry type transformer solution — designed to fit your performance, budget, and sustainability needs.

FAQ

Are dry type transformers more expensive than oil-immersed ones?

Yes, the initial cost is higher, but operational savings and longer service life make them more economical over time.

Can dry type transformers be used outdoors?

While designed mainly for indoor use, many manufacturers now offer outdoor encapsulated transformers with IP-rated enclosures.

How long do dry type transformers last?

Typically 20–25 years, depending on ventilation and load conditions.

Are dry type transformers suitable for renewable energy installations?

Absolutely. Their moisture-resistant design makes them ideal for wind farms, solar plants, and marine environments.

How do I maintain a dry type transformer?

Just keep air vents clean and check insulation resistance periodically — no oil or complex servicing required.

Table of Contents

Ready to explore your options?

Contact us today for a custom Dry Type Transformer vs. Oil-Immersed Transformer quotation — because the right transformer doesn’t just move power, it powers your entire business forward.