If you’re exploring options for power distribution, understanding

dry-type transformer types is crucial. These transformers, known for their air-cooled design and absence of oil insulation, offer unmatched safety and environmental advantages. Whether you’re considering

cast resin,

VPI, or other dry-type variants, knowing their differences ensures you pick the right fit for your facility’s needs. In this guide, we break down the key types of dry-type transformers, highlighting what sets each apart and why they’re becoming the preferred choice for modern electrical systems. Let’s dive into the essentials you need to make an informed decision.

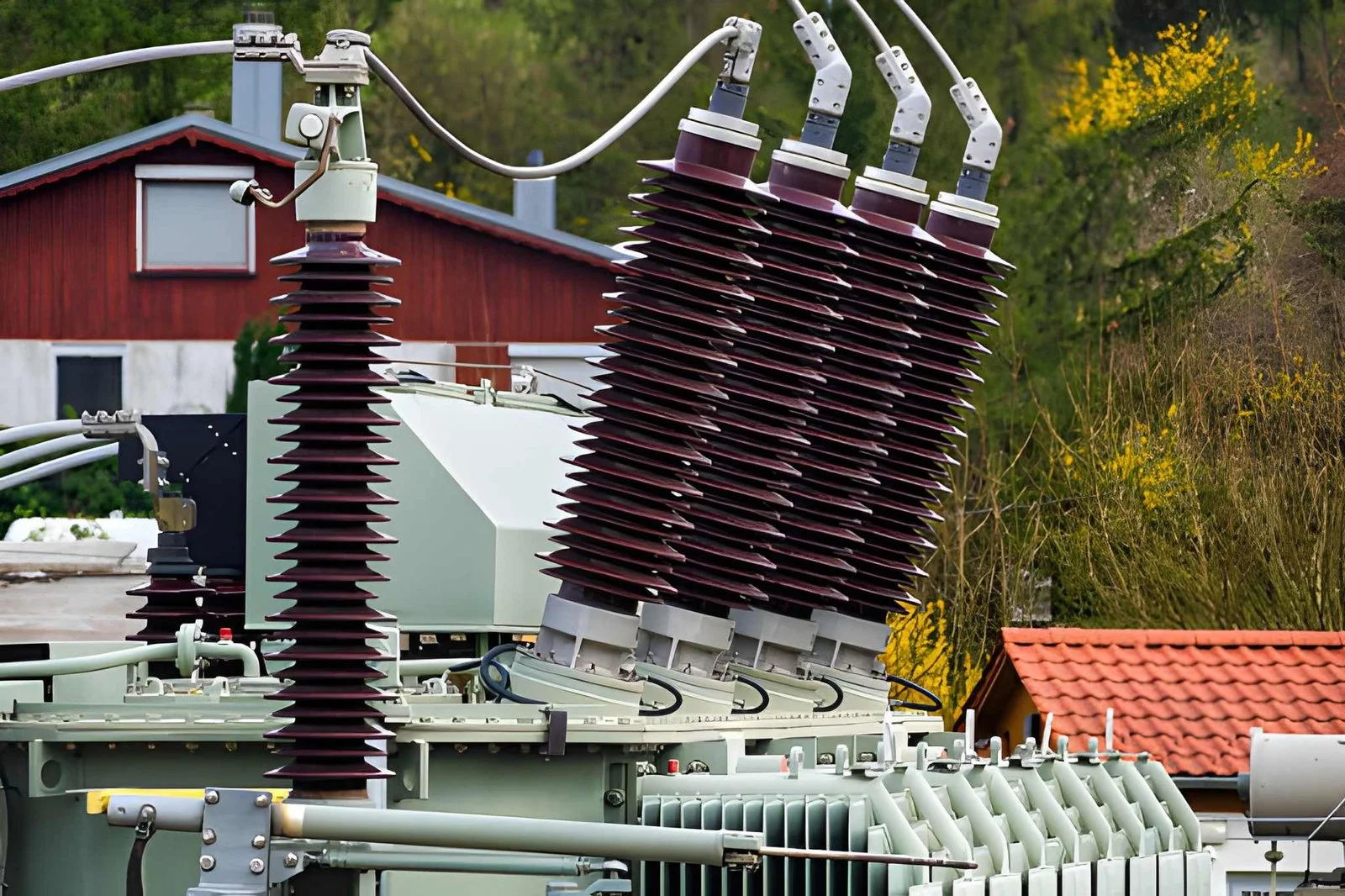

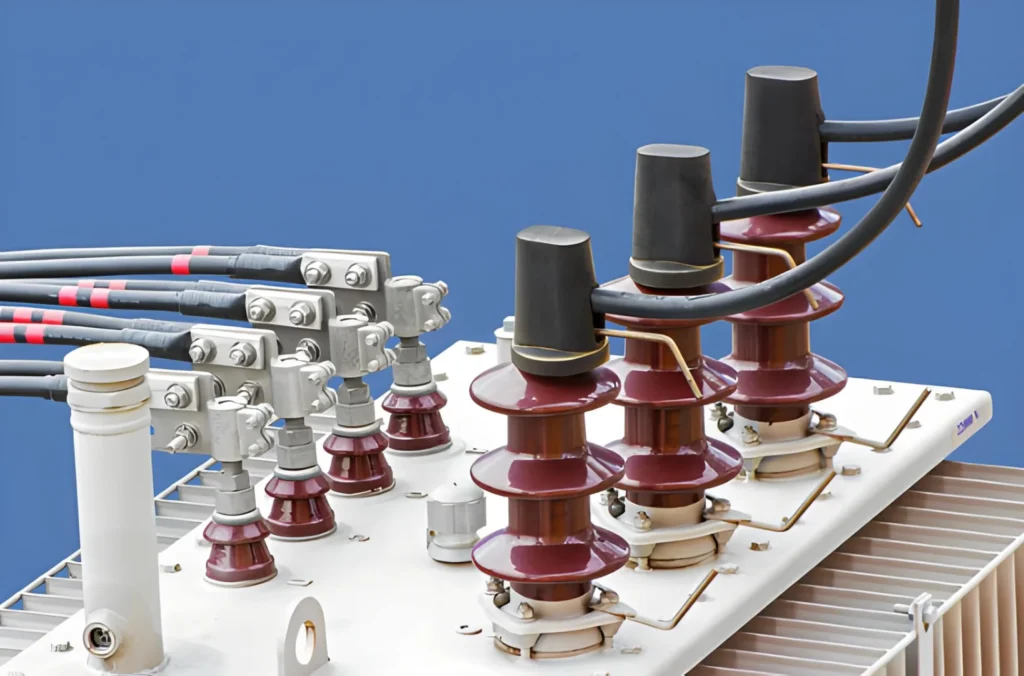

What Is a Dry-Type Transformer?

A dry-type transformer is an electrical device designed to transfer power between circuits while keeping its core and windings dry, without the use of liquid insulation like oil. Unlike traditional oil-immersed power transformers, dry-type transformers use air or solid insulation materials to cool and insulate their windings.

Basic Working Principle

Dry-type transformers operate on the same fundamental principles as other transformers—electromagnetic induction. When an alternating current flows through the primary winding, it creates a magnetic field in the core, which then induces a voltage in the secondary winding. This allows electrical energy to be transformed efficiently between different voltage levels.

Key Components

- Core: Usually made from laminated silicon steel to reduce energy losses.

- Windings: Copper or aluminum coils wrapped around the core to carry current.

- Insulation Systems: Includes epoxy resin, varnish, or other solid insulating materials instead of oil.

- Enclosure: Protective casing that can be ventilated or fully sealed to suit environmental needs.

How It Differs from Oil-Immersed Transformers

- Cooling and Insulation: Dry-type transformers rely on air or resin for cooling and insulation, eliminating the risk of oil leaks or fires.

- Safety: Without flammable oil, these transformers offer enhanced fire resistance, making them ideal for indoor and sensitive applications.

- Maintenance: They require less maintenance than oil-immersed transformers due to the absence of oil handling.

- Environmental Impact: They are eco-friendly since there is no risk of oil spills contaminating the environment.

In , dry-type transformers are a safer, low-maintenance alternative to traditional oil-immersed transformers, suitable for a wide range of applications where fire safety and environmental concerns are priorities.

Main Types of Dry-Type Transformers

Dry-type transformers come in several types, each with unique construction and features suited for different applications.

| Transformer Type |

Construction |

Features and Benefits |

| Cast Resin Transformers (CRT) |

Windings encapsulated in epoxy resin |

– Excellent insulation and moisture resistance

– Fire resistant and low smoke

– Low maintenance and long lifespan |

| Vacuum Pressure Impregnated (VPI) Transformers |

Windings impregnated with resin under vacuum and pressure |

– Superior mechanical strength

– Enhanced insulation and thermal performance

– Suitable for harsh environments |

| Ventilated (Open-Wound) Transformers |

Exposed coils with forced or natural air cooling |

– Good cooling efficiency

– Easier inspection and maintenance |

| Encapsulated (Potted or Compound-Filled) Transformers |

Windings sealed in resin or compound |

– High protection against dust and moisture

– Compact and robust design |

| Totally Enclosed Non-Ventilated (TENV) |

Enclosed casing without ventilation openings |

– Dust and moisture protected

– Suitable for dirty or humid environments |

Cast resin transformers are popular for indoor power transformer needs due to their fire-resistant epoxy resin insulation. In comparison, VPI dry type transformers are preferred where stronger insulation and mechanical durability are required.

For more details on Cast Resin Transformers, you can explore the

differences between dry-type and cast resin transformers, which highlights key features and applications.

Each type presents specific advantages, making it easier to pick a dry transformer that fits your exact needs.

Dry-Type vs. Oil-Immersed Transformers: Key Comparison

When choosing between dry-type transformer and oil-immersed power transformers, several factors come into play, especially cooling, installation, performance, and cost. Here’s a clear breakdown to help you weigh the options:

| Aspect |

Dry-Type Transformer |

Oil-Immersed Transformer |

| Cooling & Insulation |

Air-cooled with epoxy or resin insulation, no oil involved |

Oil acts as both cooling medium and insulator |

| Installation Location |

Ideal for indoor use and areas with fire restrictions |

Suited for outdoor settings but requires spill containment |

| Overload Performance |

Limited overload capacity; careful with thermal limits |

Better ability to handle overloads due to oil cooling |

| Maintenance |

Low maintenance; no oil testing needed |

Requires regular oil checks and potential filtering |

| Cost |

Usually higher upfront cost due to materials and design |

Typically lower initial cost but higher maintenance expenses |

| Safety & Environmental |

No fire hazard from oil spills, better for sensitive sites |

Risk of oil leaks and fire; environmental concerns |

Dry-type transformers rely on air flow, sometimes enhanced with fans or ventilation, to keep the system cool, while oil-immersed transformers use oil circulation to dissipate heat. This fundamental difference impacts where each type is best installed. Dry transformers are preferred indoors—like in hospitals or commercial buildings—where oil poses fire risks.

For more on these distinctions and industrial applications, check out our detailed comparison of

dry-type transformer vs oil immersed key differences.

In , dry-type power transformers offer safer, cleaner operation with lower maintenance but at a higher upfront cost and slightly reduced overload tolerance. Meanwhile, oil-immersed transformers are rugged for outdoor and heavy-duty use, but carry environmental and upkeep considerations. Choosing depends heavily on your project’s location, safety requirements, and budget.

Advantages of Dry-Type Transformers

Dry-type transformers offer several benefits that make them a smart choice for many applications. One of the biggest advantages is

enhanced fire safety—since they don’t use flammable oil, the risk of fire or explosion is much lower compared to oil-immersed transformers. This makes dry-type transformers especially suitable for

indoor power transformer setups where safety is a priority.

They are also

environmentally friendly because there’s no risk of oil leaks or spills, which can harm the environment. This aligns well with growing demands for

eco-friendly transformers in commercial and industrial spaces.

Another plus is their

low maintenance requirements. Without oil to check and replace, upkeep is simpler and less costly over time. Plus, dry transformers generally have a more

compact design, allowing for

flexible installation in tight or sensitive environments like hospitals, schools, or data centers.

Overall, these features make dry-type transformers a reliable, safe, and green solution for modern power needs. For more on the benefits and smart power solutions of dry transformers, check out our detailed guide on

dry-type transformer safety and smart power.

Disadvantages and Limitations of Dry-Type Transformers

While dry-type transformers offer many benefits, they do come with a few drawbacks to consider:

- Higher Initial Cost: Compared to oil-immersed transformers, dry-type transformers generally have a higher upfront price due to their specialized insulation materials and manufacturing processes.

- Limited Overload Capacity: Dry-type transformers typically handle less overload than oil-immersed models, which can be a limitation in applications with frequent or heavy load surges.

- Higher Noise Levels: Some dry-type transformers, especially ventilated or cast resin types, can produce more audible noise during operation compared to their oil-filled counterparts.

- Sensitivity to Dust and Humidity: Certain dry transformer designs, such as those with open ventilation, are more vulnerable to dust accumulation and moisture, which can affect insulation life and performance.

Understanding these limitations can help in choosing the right transformer type based on your project environment and operational needs. For applications where environmental factors are challenging, proper enclosure selection and maintenance become key.

Common Applications of Dry-Type Transformers

Dry-type transformers are widely used across many sectors thanks to their safety and reliability. You’ll often find them in commercial buildings, hospitals, schools, and high-rises where fire safety is a top priority. Their design makes them perfect for indoor power transformer needs where minimal risk and low maintenance are essential.

In industrial facilities and data centers, dry-type transformers provide reliable power while reducing downtime risks. They’re also becoming popular at renewable energy sites, supporting solar and wind power setups with eco-friendly and fire-resistant transformer solutions.

Additionally, any area that demands strict environmental compliance or has high fire safety regulations will benefit from dry-type transformers. Their oil-free construction eliminates spill risks, making them ideal for such sensitive environments.

For tailored options that meet complex power needs, consider exploring medium and high voltage power solutions, which can be customized specifically for these demanding applications.

Factors to Consider When Selecting a Dry-Type Transformer

Choosing the right dry-type transformer means looking closely at several key factors to match your power needs and installation environment.

- Voltage rating and kVA capacity: Make sure the transformer’s voltage and power rating (kVA) fit your load requirements perfectly to avoid underperformance or overspending.

- Insulation class and temperature rise: Check the insulation type and temperature rise limits, as these impact the transformer’s durability and efficiency, especially under continuous load.

- Enclosure type (NEMA ratings): Depending on where you install the transformer—indoors, outdoors, or in harsh environments—choose the right enclosure with suitable NEMA ratings for protection against dust, moisture, and other elements.

- Efficiency standards and energy losses: Look for dry-type transformers that meet or exceed efficiency standards to reduce energy losses and save on operating costs over time.

- Customization options: Depending on your project’s unique needs, consider suppliers who can offer tailored solutions like specific tap changers, mounting styles, or enhanced fire-resistant features.

For further guidance on selecting the perfect transformer to meet your requirements, check out our detailed guide on

how to select the right dry-type transformers for your project.

Why Choose Kampa Dry-Type Transformers?

Kampa offers a wide range of

high-quality dry-type power transformers designed to meet diverse industrial and commercial needs. Their products stand out for excellent performance, reliability, and strict adherence to international standards, ensuring your power systems run smoothly and safely.

Key Benefits of Kampa Dry-Type Transformers

| Feature |

Benefit |

| Customization Options |

Tailored solutions for specific voltage, kVA, and enclosure needs |

| Robust Insulation Systems |

Enhanced durability and longer service life |

| Compact & Flexible Design |

Fits indoor and space-constrained installations easily |

| International Certifications |

Compliance with global safety and efficiency regulations |

| Low Maintenance |

Minimizes downtime and reduces operational costs |

Partnering with a trusted transformer supplier like Kampa means you get not just a product, but a solution backed by expert support and proven quality. Whether you need eco-friendly,

fire-resistant dry-type transformers or specialized units, Kampa has you covered.

Explore Kampa’s full range of reliable

dry-type power transformers and see why they’re a top choice for global customers looking for quality and performance. For comparison, you can also check their

oil-immersed power transformers to find the best fit for your project.