If you’re exploring dry type transformer insulation, you’re likely aiming to understand what makes these systems a standout choice for safe, efficient power distribution—especially indoors. Unlike traditional oil-filled transformers, dry-type insulation relies on solid and air-based materials to deliver robust electrical isolation and thermal endurance without the hazards of flammable liquids. In this post, you’ll discover why advanced insulation materials like Nomex® and epoxy resins are revolutionizing transformer safety and performance, and how selecting the right insulation class can extend lifespan while minimizing maintenance. Whether you’re an engineer, facility manager, or procurement specialist, this guide will break down everything you need to know about dry type transformer insulation—from materials and thermal ratings to real-world benefits—and show why partnering with a trusted supplier like Kampa makes all the difference. Let’s get into the essentials.

What Is Dry-Type Transformer Insulation?

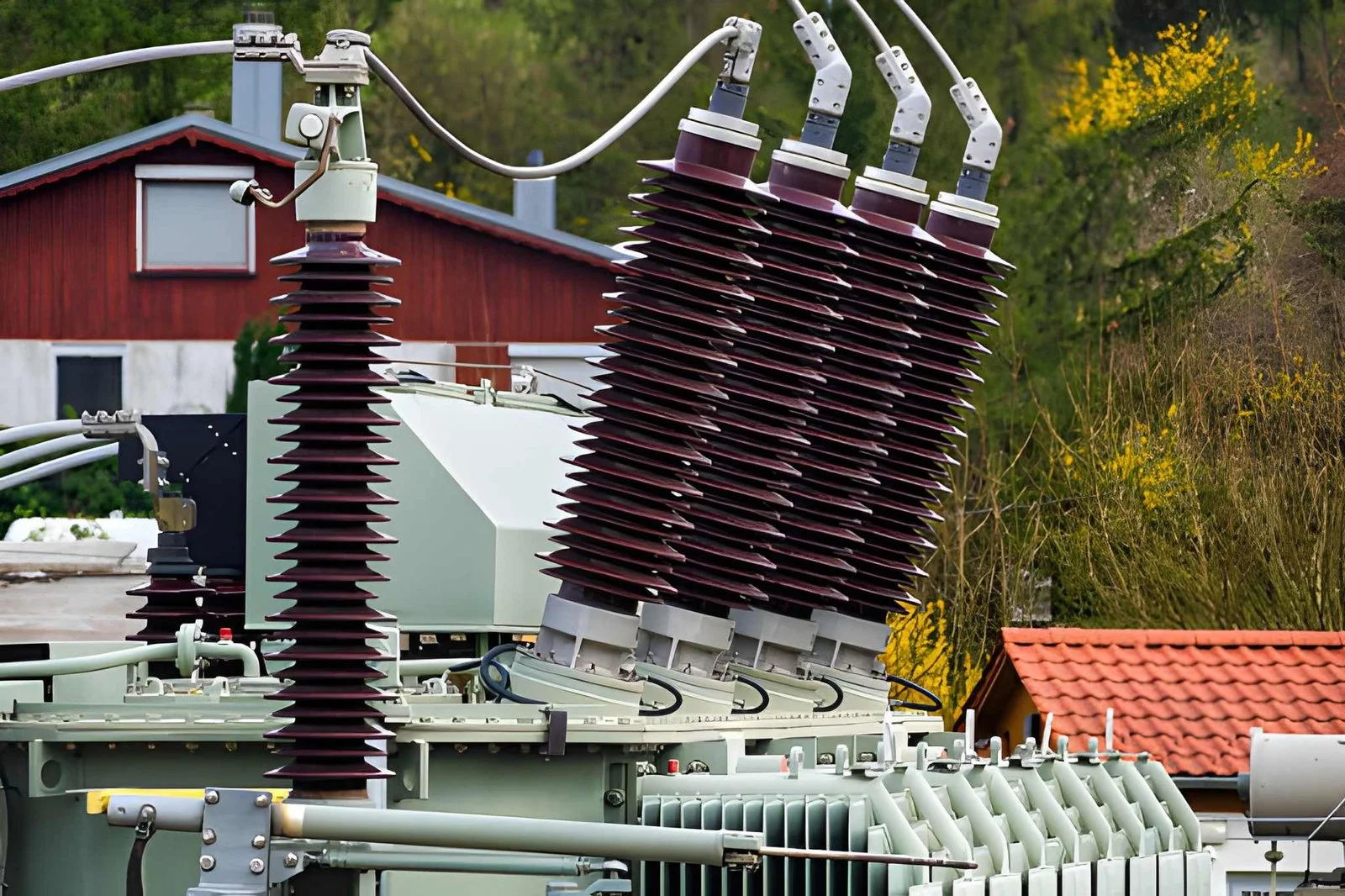

Are you wondering what dry-type transformer insulation is and why it matters? Simply put, dry-type transformer insulation refers to the materials and methods used to protect the windings and core of a transformer without using liquid coolant like oil. Its core function is to electrically isolate conductors, prevent short circuits, and provide thermal endurance under operating temperatures.

There are two primary types of dry-type transformer insulation widely used in the industry:

- Open-Wound VPI (Vacuum Pressure Impregnation): This method uses aramid paper insulation like Nomex® combined with varnishes to impregnate and seal the windings. The vacuum pressure impregnation ensures excellent dielectric strength and mechanical stability. Open-wound VPI transformers offer better cooling due to exposed windings.

- Cast Resin Insulation: In this type, the windings are encapsulated in epoxy resin. This solid insulation creates a rugged, moisture-resistant barrier that is fire resistant and ideal for harsh or polluted environments. Epoxy cast resin transformers are known for their high mechanical strength and are easy to maintain.

Both types form the backbone of dry-type transformer materials, ensuring safety, reliability, and efficient thermal management without the use of flammable liquids. Understanding these insulation types helps in selecting the right transformer for your specific application needs.

Common Insulation Materials in Dry-Type Transformers

Dry type transformer insulation relies on several key materials to ensure durability, safety, and performance. One of the most popular is aramid paper insulation, commonly known by the brand name Nomex®. This material offers excellent thermal endurance and mechanical strength, making it a staple in high-quality transformers.

Another crucial component is epoxy resins, widely used in cast resin transformers for their superior protection against moisture and contaminants. Epoxy resins provide a solid, fire-resistant barrier that helps enhance the overall reliability and lifespan of the transformer.

Beyond these, polyester films and composites play a vital role in improving electrical insulation and flexibility. Alongside this, fiberglass reinforcements add mechanical stability and help withstand harsh environments by boosting strength without compromising insulation properties.

The industry is also evolving with emerging materials that focus on eco-friendly, high-performance insulation, improving safety standards while reducing environmental impact.

For more about cutting-edge insulation solutions and product options, you can explore Kampa’s comprehensive range of dry-type transformer insulation series.

Insulation Classes and Temperature Ratings

Dry type transformer insulation is categorized into different thermal classes based on its temperature endurance. The most common insulation classes you’ll find are Class F, Class H, and Class R. Class F insulation can handle temperatures up to 155°C, Class H up to 180°C, and Class R even higher, reaching around 220°C. These classes define the maximum temperature the insulation materials can withstand without degrading, which is crucial for the transformer’s reliability and lifespan.

Temperature rise is another important factor—transformers generate heat during operation, causing the insulation temperature to increase beyond ambient levels. Proper insulation class selection helps manage this thermal stress. For example, a Class F dry type transformer insulation will tolerate typical temperature rises without breaking down, ensuring long-term performance.

Standard temperature ratings guide engineers in design and material choice, directly impacting transformer size, cooling methods, and life expectancy. Choosing the right insulation class leads to better thermal endurance and reduces risks of partial discharge or insulation failure, especially in high-voltage dry transformers.

For specialized applications, such as in environmentally sensitive areas, manufacturers often use higher thermal class materials like epoxy cast resin or aramid paper insulation (Nomex®), which offer both heat resistance and fire safety. Understanding these insulation classes and temperature ratings helps to select dry type transformer materials that meet specific operational demands efficiently.

Advantages of Dry-Type Transformer Insulation

Dry-type transformer insulation offers several key benefits that make it a preferred choice for many applications worldwide.

- Fire Safety: Unlike oil-filled transformers, dry-type transformers use insulation materials like epoxy cast resin and aramid papers (Nomex®), which are inherently fire-resistant. This reduces the risk of fire hazards, making them ideal for indoor and urban settings where safety is a priority.

- Environmental Benefits: Dry transformers avoid the use of flammable liquids, which means no risk of oil leaks contaminating the environment. Eco-friendly transformer insulation materials also support better sustainability and easier disposal.

- Low Maintenance: Thanks to insulation types such as vacuum pressure impregnation (VPI) and cast coil insulation, these transformers require less frequent upkeep. Their sealed construction protects against dust and moisture, lowering overall maintenance costs.

- Moisture and Pollution Resistance: Dry-type transformers handle high humidity and polluted environments better. The insulation materials, including epoxy resins and fiberglass reinforcements, resist moisture absorption, preventing deterioration and extending transformer life.

- Noise Reduction: The solid insulation structure and tight winding design help minimize noise levels, making dry-type transformers a quieter option compared to oil-filled counterparts.

These advantages position dry-type transformers as reliable, safe, and cost-effective solutions, especially in sensitive locations. For detailed options, you can explore our range of cast resin current transformers and fully insulated voltage transformers.

Dry-Type vs. Oil-Filled Transformer Insulation

When comparing dry-type transformer insulation to oil-filled transformer insulation, the differences in insulation medium play a big role in performance and application. Dry-type transformers use solid insulation materials like aramid paper (Nomex®) and epoxy cast resin, while oil-filled transformers rely on mineral or synthetic oil both for insulation and cooling.

Cooling and Capacity:

Oil-filled transformers benefit from the oil’s excellent heat transfer, allowing for higher capacity and better temperature control. Dry-type transformers depend on air cooling and advanced insulation like vacuum pressure impregnation (VPI) or cast resin, which limits their capacity but improves safety.

Safety and Environmental Impact:

Dry-type transformers score high on fire safety since they contain no flammable liquids, making them a preferred choice in indoor or environmentally sensitive areas. They are also more eco-friendly, with less risk of soil or water contamination compared to oil-filled types.

Maintenance and Cost:

Dry-type transformer insulation typically demands less maintenance because there is no oil to monitor or replace. Oil-filled transformers require regular oil testing and handling, which adds ongoing costs. However, oil-filled units often have a lower initial price and are suited for heavy industrial loads.

Application Suitability:

Dry transformers are ideal for commercial buildings, hospitals, and places where fire concerns and noise reduction matter. Oil-filled transformers still dominate in large power plants or outdoor substations where high power and robust cooling are key.

For a deeper look into these differences and guidance on choosing the right technology for your needs, check out our detailed comparison of dry-type vs oil-immersed transformers for industrial application.

Factors Influencing Dry-Type Transformer Insulation Performance and Selection

Choosing the right dry type transformer insulation depends on several key factors that directly impact its durability and efficiency. Here’s what matters most:

- Load and Operating Conditions: The insulation must handle the transformer’s expected load, including peak and continuous currents. Higher loads can cause more heat, challenging the insulation’s thermal endurance and possibly leading to premature failure.

- Environmental Stress: Dry type transformers often face moisture, dust, and pollution, especially in outdoor or industrial settings. Insulation materials like aramid papers (Nomex®) or epoxy cast resin are selected based on their resistance to moisture and pollutants to maintain reliable performance.

- Harmonic and Electrical Stresses: Harmonics from non-linear loads create electrical stresses that impact insulation longevity. Materials with good dielectric strength and partial discharge resistance are preferred to combat these effects.

- Testing Standards Compliance: Insulation must meet international standards such as IEC, IEEE, and ANSI regarding temperature rise, partial discharge limits, and fire resistance. Compliance ensures safety, reliability, and extended transformer life.

- Challenges in Selection: Balancing cost, environmental conditions, and expected lifespan is not easy. For example, cast coil insulation offers excellent protection but can be more expensive than VPI dry type transformers with open-wound designs.

- Selection Tips:

- Consider the specific application and environment.

- Prioritize insulation classes based on temperature ratings.

- Opt for proven materials like Nomex® for thermal endurance.

- Engage suppliers offering customization to match your requirements.

Understanding these factors helps you pick insulation that boosts transformer reliability and cuts maintenance costs. For detailed advice on choosing dry type transformers that fit your needs, check out our guide on how to select the right dry type transformers for your project.

Maintenance and Testing Best Practices for Dry-Type Transformer Insulation

Keeping dry-type transformer insulation in top shape ensures reliability and extends the transformer’s lifespan. Regular routine inspections are essential—these include visual checks for dust, dirt, cracks, or any physical damage to the cast resin or VPI dry type transformer insulation. Look out for signs of discoloration or overheating which could indicate insulation stress.

Diagnostic tests are just as important. Common methods include insulation resistance testing, partial discharge detection, and thermal imaging. These tests help catch early warning signs of insulation breakdown or moisture ingress before major failures occur. For example, detecting partial discharge early can prevent costly downtime and extend the life of Nomex insulation transformer components.

To maximize lifespan, follow these tips:

- Keep the environment clean and dry to avoid contamination and humidity impact.

- Ensure proper transformer temperature rise monitoring, as excessive heat speeds insulation aging.

- Schedule periodic professional maintenance focusing on insulation health.

- Use approved cleaning methods suitable for epoxy cast resin transformer surfaces to avoid damage.

Adhering to these maintenance and testing best practices ensures your dry-type transformer insulation remains reliable, safe, and efficient throughout its service life. For tailored support and advanced diagnostic solutions, exploring expert suppliers ensures you get the latest tools for upkeep and performance monitoring.

Why Choose Kampa for Dry-Type Transformers

Kampa stands out as a trusted dry-type transformer supplier with deep expertise in dry type transformer insulation technology. We focus on delivering high-quality products that match the growing demands of global markets, ensuring reliability and safety.

What Sets Kampa Apart

| Feature | Benefit |

|---|---|

| Advanced Insulation Tech | Uses premium materials like Nomex® aramid paper and epoxy cast resin for superior durability and thermal endurance. |

| Wide Product Range | From standard VPI dry type transformers to custom designs tailored to your specific needs. |

| Customization Options | Adapt transformers to fit unique specifications, including voltage rating, power capacity, and insulation class. |

| Proven Reliability | Rigorous testing and quality control ensure excellent performance under harsh conditions. |

| Real-World Case Studies | Successful projects in industrial, commercial, and renewable energy sectors showcase our expertise and product resilience. |

Why This Matters to You

- Safety & Longevity: Our dry type transformer insulation materials enhance fire resistance and reduce maintenance, helping your operations run smoothly.

- Cost-Efficiency: Custom options and durable designs reduce long-term costs and downtime.

- Global Support: Whether you need standard models or high-voltage dry transformers, Kampa delivers with competitive transformer prices and tailored solutions.

Explore our dry-type power transformers to find the best fit for your project, backed by industry-leading insulation technology and quality assurance.