What Is a Dry-Type Transformer?

A dry-type transformer is an electrical device that transfers energy between circuits through electromagnetic induction without using any liquid insulation like oil. Instead, it relies on air or epoxy resin for insulation, making it safer and cleaner than traditional oil-filled transformers.

Core Definition and Working Principle

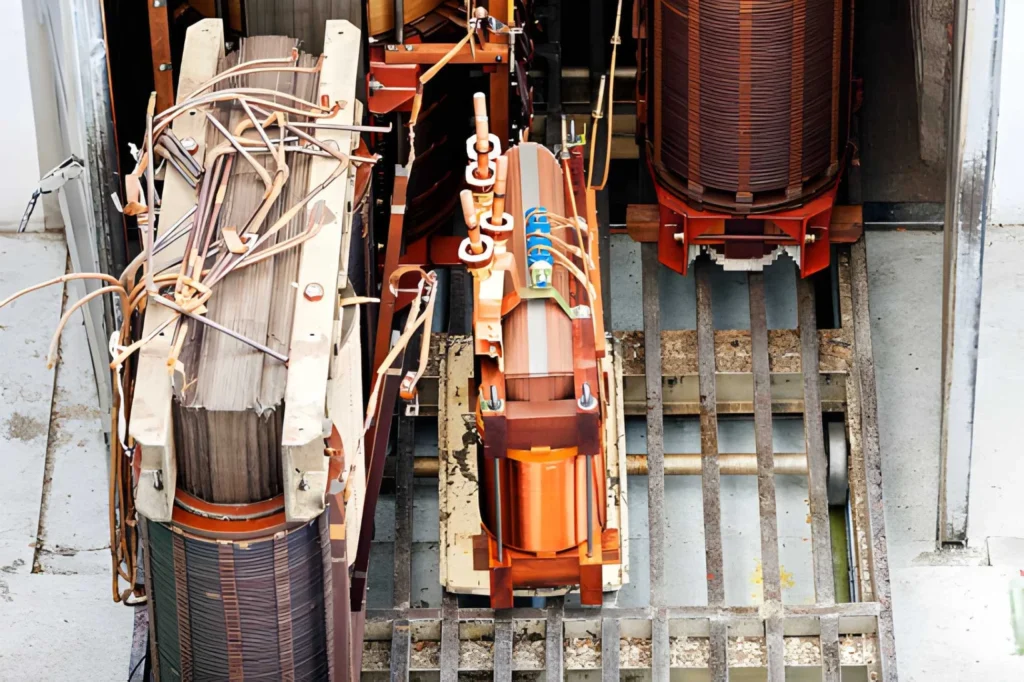

Dry-type transformers operate on the same basic principle as other transformers: they use coils (windings) wrapped around a magnetic core to step voltage up or down. When AC voltage is applied to the primary winding, it creates a magnetic field in the core. This induces a voltage in the secondary winding, efficiently transferring power while isolating circuits.

Key Components and Materials

- Core: Usually made of high-quality silicon steel for low energy loss.

- Windings: Typically copper or aluminum conductors, insulated with materials like epoxy resin.

- Insulation: Air or cast epoxy resin (common in cast resin transformer customization).

- Enclosure: Protects internal parts and varies depending on where the transformer will be installed.

Comparison with Oil-Filled Transformers

| Feature | Dry-Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Insulation Medium | Air or epoxy resin | Mineral oil or synthetic oil |

| Fire Risk | Low (non-flammable materials) | Higher (flammable oil) |

| Maintenance | Low, no oil checks needed | Regular oil testing and maintenance |

| Installation | Suitable for indoor and close-quarter spaces | Usually outdoors or well-ventilated areas |

| Environmental Impact | Eco-friendly, no oil leaks | Risk of oil leaks, environmental hazard |

| Noise Level | Generally quieter | May have higher noise due to oil cooling |

Dry-type transformers are increasingly preferred in settings where fire safety, environmental concerns, and low maintenance are priorities. They are a versatile, energy-efficient choice for many modern applications.

Advantages of Dry-Type Transformers

Dry-type transformers offer several benefits that make them a preferred choice across many industries, especially when safety and reliability are priorities.

Fire Safety and Indoor Use

- No oil means zero risk of oil leaks or fires, making them ideal for indoor environments like commercial buildings and hospitals.

- Their design meets stricter fire codes, providing safer operation in confined spaces.

Low Maintenance and Long Lifespan

- With no oil to monitor or replace, dry-type transformers require less upkeep overall.

- Their sealed construction protects internal components from dust and moisture, extending service life while reducing downtime.

Eco-Friendly and Clean Operation

- Absence of oil eliminates environmental hazards related to spillages or disposal.

- Made with materials like epoxy resin, these transformers are eco-friendly and help companies meet sustainability goals.

Energy Efficiency and Quiet Performance

- Dry-type transformers generally have higher energy efficiency, cutting energy losses and saving operational costs.

- They operate quietly, ideal for noise-sensitive areas such as data centers and healthcare facilities.

| Advantage | Key Benefit | Typical Application |

|---|---|---|

| Fire Safety | No oil-related hazards | Indoor commercial, hospitals |

| Low Maintenance | Less frequent servicing | Industrial plants, offices |

| Eco-Friendly Operation | No environmental contamination | Green energy projects |

| Energy Efficiency & Quiet | Reduced energy costs and noise | Data centers, high-rises |

Choosing a custom dry type transformer means you can maximize these advantages tailored to your exact needs. For a detailed comparison with oil-filled options, check out our breakdown of dry-type versus oil-immersed transformers.

When Do You Need a Customized Dry-Type Transformer?

Choosing a custom dry type transformer makes sense when standard options don’t fit your specific needs. Here are common scenarios where customization is crucial:

Unique Voltage and Space Requirements

- Custom voltage ratios or unusual kVA ratings tailor the transformer precisely to your power system.

- Limited physical space demands compact designs or special enclosure types to fit the installation site.

Handling Harmonic Loads and Harsh Environments

- Sensitive electronics or industrial equipment often generate harmonic currents needing a K-factor rated transformer or harmonic mitigation features.

- Dust, moisture, high temperatures, or corrosive environments require robust insulation and sealed enclosures like NEMA 3R or 4X for durability.

Industries Benefiting Most from Customization

| Industry | Typical Needs | Custom Features |

|---|---|---|

| Data Centers | High reliability, harmonic filtering | Electrostatic shielding, forced air cooling |

| Manufacturing Plants | Handling heavy equipment, harsh conditions | Vibration mounts, epoxy resin insulation |

| Healthcare Facilities | Critical power, noise reduction | Quiet operation, stringent safety standards |

| Renewable Energy | Variable loads, outdoor use | Medium voltage customization, rugged enclosures |

Custom dry type transformers meet these complex needs better than off-the-shelf units. For example, you might combine a dry type power transformer with custom taps and accessories like temperature monitors or surge protectors to optimize performance.

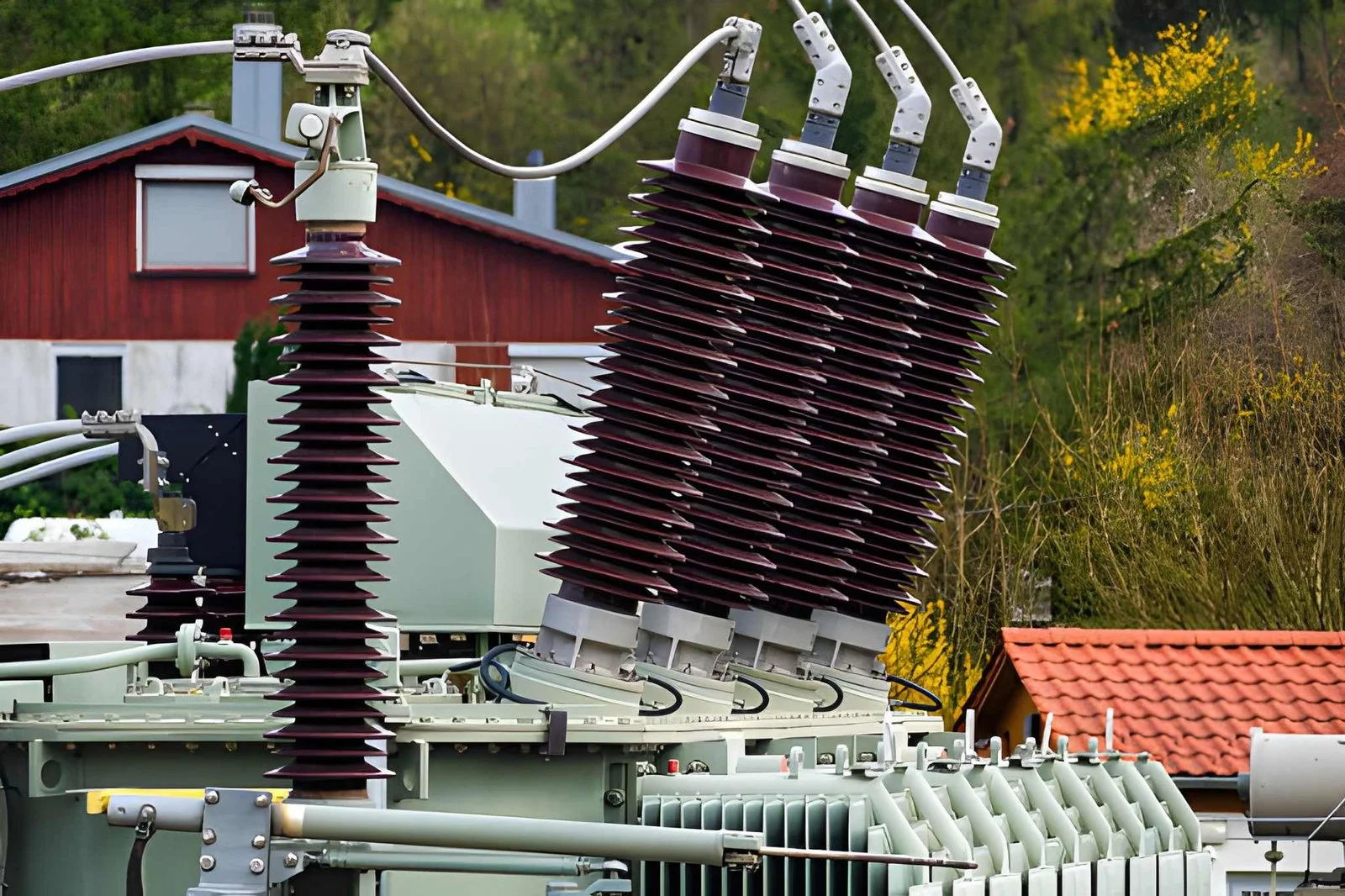

Need a transformer with unique specifications? Check out Kampa’s specialized range of voltage transformers tailored for precise applications, such as their fully enclosed cast resin voltage transformers designed for harsh environments.

Customizing ensures your dry type transformer works efficiently and safely in challenging settings, delivering long-term value.

Key Customization Options for Dry-Type Transformers

Custom dry type transformers can be tailored in many ways to fit your exact needs. Here’s a quick overview of the main options:

| Customization Aspect | Details / Choices |

|---|---|

| Electrical Parameters | kVA rating, voltage levels, frequency, impedance, tap changer options |

| Winding Materials | Copper (better conductivity) or Aluminum (cost-effective) |

| Insulation Classes | Different classes based on temperature rise and operating environment |

| Enclosure Types & Ratings | NEMA 1 (indoor), 3R (outdoor rainproof), 4X (corrosion resistant), etc. |

| Special Features | K-factor rating for harmonic loads, electrostatic shielding, noise reduction, forced air cooling |

| Accessories | Temperature monitors, surge protection devices, vibration mounts, customized paint finishes, portability options |

Electrical Parameters

You can adjust key specs such as power rating (kVA), voltage, and frequency to perfectly match your system. For example, transformers designed for harmonic mitigation require specific K-factor ratings to handle non-linear loads safely.

Winding Materials

Copper windings offer lower losses and better efficiency, ideal for high-performance setups. Aluminum windings help reduce initial costs for budget-sensitive projects.

Insulation and Temperature Rating

Custom insulation classes and temperature rise designs ensure transformers last longer even under tough conditions, especially important in industrial applications.

Enclosure Ratings

Choosing the right enclosure protects your transformer from environmental challenges:

- NEMA 1: Standard indoor use

- NEMA 3R: Outdoor resistance to rain

- NEMA 4X: Additional corrosion protection

Special Features

You can add advanced features like electrostatic shielding to reduce electromagnetic interference, or forced air cooling for higher load capacities and quieter operation.

Accessories

Enhance transformer reliability and maintainability with built-in temperature monitors, surge protection, vibration absorbing mounts, and bespoke paint for specific environments. Some customization even improves portability for easier installation.

For a deeper dive into advanced transformer design options and material choices, check out Kampa’s dry-type transformer core technology, design, and applications, which highlights many of these customizable features tailored for diverse industrial needs.

The Customization Process with Kampa

At Kampa, customizing your dry type transformer starts with an initial consultation where we gather your specific needs—voltage, size, environment, and any unique requirements. This step ensures we fully understand your project’s scope before moving forward.

Next is the engineering design and specification review. Our expert team analyzes your inputs and develops a tailored design that meets your electrical and mechanical requirements. Whether you need a cast resin transformer customization or specific insulation classes, we take care of the technical details.

Once the design is approved, we move to prototyping, testing, and compliance verification. This phase guarantees your custom dry type transformer meets safety standards and performs reliably under your expected conditions.

After testing, we begin manufacturing using high-quality materials like vacuum pressure impregnated insulation and copper or aluminum windings. Throughout production, we maintain strict quality assurance processes to ensure consistency.

Finally, we provide accurate delivery timelines and support post-sales with services like technical assistance, warranties, and guidance. Choosing Kampa means you get a reliable partner for your dry type transformer needs, from design to aftercare.

For detailed circuit protection options complementing your transformer, explore our VS1 Series Vacuum Circuit Breaker.

Applications of Customized Dry-Type Transformers

Customized dry type transformers are vital across many industries that demand reliable, safe, and efficient power solutions. Here are some key applications where their tailored features make a real difference:

- Commercial Buildings and High-Rises: Custom dry type transformers fit seamlessly into limited spaces and complex electrical systems in offices and tall buildings, ensuring stable power distribution without the fire risks associated with oil-filled types.

- Data Centers and Critical Infrastructure: These transformers provide dependable power with minimal interruption. Customization supports specific voltage needs, harmonic mitigation, and quiet operation, essential for sensitive equipment in data centers and telecom hubs.

- Hospitals and Healthcare Facilities: Safety, low noise, and clean operation are crucial here. Customized transformers with advanced insulation and temperature monitoring cater to strict healthcare standards while maintaining energy efficiency.

- Industrial Plants and Manufacturing: Harsh environments and heavy loads in factories call for rugged, purpose-built dry type power transformers that endure temperature variations and electrical stresses, often including K-factor ratings for handling harmonic loads.

- Renewable Energy Systems: Customization helps optimize transformers for solar farms and wind power installations by matching unique voltage profiles and enhancing efficiency to suit green energy demands.

- Marine and Hazardous Area Installations: Specialized dry type transformers with protective enclosures and corrosion-resistant materials meet the strict safety and reliability standards required in maritime and hazardous zones.

For more on different dry type transformer types suited for varying industry needs, check out Kampa’s in-depth guide on dry-type power transformers. Customized solutions ensure your project gets precisely what it needs, balancing performance with safety and regulatory compliance.

Factors Influencing Cost and Pricing of Customized Dry-Type Transformers

When considering a custom dry type transformer, price varies significantly based on several key factors. First, the level of customization directly impacts cost—more specific voltage settings, complex winding designs, or special insulation classes usually mean higher expenses due to added engineering and materials.

Material choices also affect pricing. For instance, copper windings typically cost more than aluminum but offer better efficiency and durability. Larger transformer sizes and higher kVA ratings naturally require more raw materials and labor, pushing prices up.

Balancing your budget with performance needs is crucial. Sometimes, opting for standard enclosure types like NEMA 1 or 3R can reduce costs, while advanced features such as K-factor ratings or forced air cooling may increase price but deliver long-term operational savings.

To sum up:

- Customization level: More tailored specs raise costs

- Materials: Copper vs. aluminum windings impact price and efficiency

- Size and capacity: Larger transformers cost more

- Performance vs. budget: Choose features wisely to optimize value

For detailed transformer enclosure options and tailored solutions, you might want to explore the industrial power distribution and protection offerings available to fit specific project requirements.

Why Choose Kampa as Your Dry-Type Transformer Supplier

When it comes to a custom dry type transformer, Kampa stands out as a trusted manufacturer. Here’s why choosing Kampa makes a difference:

| Why Kampa? | Details |

|---|---|

| Expertise in Custom Engineering | Tailored design based on your exact electrical and environmental needs. |

| Advanced Manufacturing | Uses the latest tech for consistent quality and performance. |

| Commitment to Quality | Rigorous quality checks and compliance with global standards. |

| Efficiency and Innovation | Focus on energy-efficient dry type power transformers that reduce losses. |

| Competitive Pricing | Balancing top quality with cost-effective solutions. |

| Reliable Delivery | Timely shipments ensuring your project schedule stays on track. |

| Customer Success Stories | Proven track record with satisfied clients across industries worldwide. |

Kampa’s wide range of cast resin transformer customization options and accessories lets you optimize transformers for every application—from industrial plants to data centers. Our ability to customize features like K-factor rating, enclosure types, and harmonic mitigation makes us the go-to dry type transformer supplier you can trust.

Explore how Kampa can meet your needs with customized, reliable, and energy-efficient solutions that fit your budget and timeline. Visit our dry type transformer supplier for reliable power solutions page to learn more.

FAQs about Customization Dry Type Transformers

What is the typical lead time for a custom dry type transformer?

Lead times usually range from 6 to 12 weeks, depending on the complexity of specifications like kVA rating, enclosure type, and special features. Early consultation helps ensure your custom dry type transformer is delivered on time without compromising quality.

Can dry type transformers be used outdoors?

Yes, specially designed outdoor dry type transformers with appropriate enclosure ratings like NEMA 3R or 4X can withstand weather conditions. Customizing the enclosure and adding protective features ensures durability and safe operation in outdoor environments.

Do customized dry type transformers offer better energy efficiency?

Absolutely. Tailoring parameters such as core design, winding materials, and cooling methods can enhance efficiency. Energy efficient dry type transformers reduce losses and operating costs, making customization a smart investment.

Which safety and performance standards apply to customized dry type transformers?

Custom dry type transformers must comply with global standards like IEEE, ANSI, IEC, and UL certifications. During the customization process, all designs undergo rigorous testing and compliance checks to meet these safety and performance benchmarks.

For more detailed insights on dry type transformer design and safety, explore our guide on understanding dry type transformer safety and smart power solution and the differences between dry type vs cast resin transformers.