Table of Contents

Product Range Overview

Kampa offers a comprehensive range of instrument transformers products designed to meet diverse electrical measurement and protection needs. Our portfolio includes:

- Current Transformers (CTs): Available in multiple configurations such as window type, busbar mounting, rail mounting, wound primary, and split-core models, tailored for precise current measurement and protection.

- Potential Transformers (PTs) / Voltage Transformers (VTs): Single-phase and three-phase options suitable for accurate voltage measurement and system monitoring.

- Combined CT/PT Units: Integrated solutions combining current and potential transformers within a single compact assembly to optimise space and simplify installation.

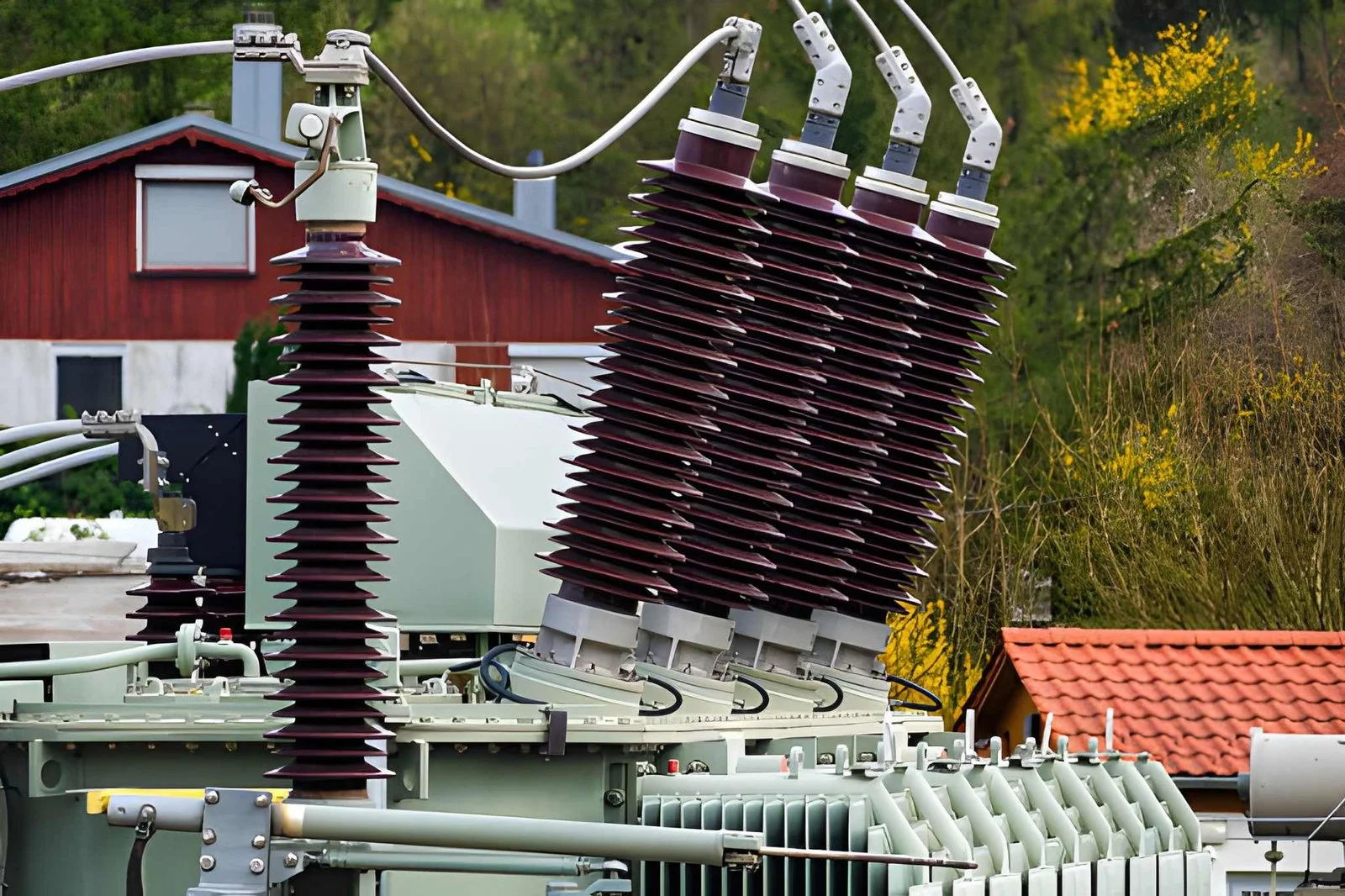

Our instrument transformers cater to both low voltage systems (up to 720V) and medium voltage applications (up to 36kV or customized higher voltage ratings), serving a wide spectrum from industrial control panels to utility substations. This extensive product range ensures reliable metering and protection across varied electrical infrastructures worldwide.

Key Features & Benefits of Instrument Transformers Products

Our instrument transformers products, including current transformers (CTs) and potential transformers (PTs) / voltage transformers (VTs), deliver top-notch performance with features designed to meet global standards and demanding applications. Here’s what sets them apart:

| Feature | Details | Benefits |

|---|---|---|

| Accuracy Classes | Metering: 0.2, 0.5, 1.0; Protection: 5P, 10P, PX | Precise energy measurement & reliable protection |

| Burden VA Ratings | Wide range of burden ratings for diverse load conditions | Flexibility in application without loss in accuracy |

| Insulation Systems | Epoxy resin cast, oil-paper insulation options | Robust, durable, and suitable for various environments |

| Standards Compliance | Fully compliant with IEC, IEEE/ANSI International standards | Ensures safety, quality, and interoperability |

| Service Life & Maintenance | Designed for long service life with minimal maintenance | Cost-effective and reliable over time |

| Eco-Friendly Options | Environmentally friendly materials and processes | Reduces environmental impact without sacrificing performance |

Our epoxy resin cast current transformers, such as those used in indoor cast resin current transformers, offer excellent mechanical strength and resistance to moisture, ensuring long-term stable performance even in harsh conditions.

By choosing our CT PT products, you benefit from superior metering and protection accuracy, wide application flexibility thanks to various burden VA ratings, plus robust insulation that stands up to the toughest environments—all while meeting strict industry standards to support power system safety and efficiency.

Types of Instrument Transformers

Instrument transformers come in different types to suit various applications. Here’s a quick overview of the common options:

| Type | Description | Main Use |

|---|---|---|

| Current Transformers (CTs) | – Window Type: Primary conductor passes through. |

- Busbar Mounting: Fixed around busbars.

- Rail Mounting: Mounted on rails for easy install.

- Wound Primary: Primary winding inside the CT.

Split-Core: Easy to install on existing cables without disconnecting. Metering, protection, and control in LV and MV networks - Single-Phase & Three-Phase: For different system setups.

Line-to-Ground & Line-to-Line types: For measuring different voltage points. Voltage measurement for metering and protection .

Metering vs. Protection Classes

- Metering CTs/PTs: High accuracy classes (0.2, 0.5, 1.0), designed to measure exact current or voltage for billing and monitoring.

- Protection CTs: Designed for durability and fast response in fault conditions, accuracy classes like 5P, 10P, PX. Focus on handling high fault currents without saturation.

Choosing between metering or protection class depends on whether you prioritize accuracy for billing or robustness for safety systems.

For installation ease and flexibility, split-core CTs and combined CT/PT units are often favored in modern systems. When working with medium voltage ranges or custom setups, specialized designs may be required, including epoxy resin cast insulation for durability.

To understand more about insulation options related to instrument transformers, check out our guide on dry type transformer vs cast resin.

Technical Specifications of Instrument Transformers

Understanding the technical specs of our instrument transformers products is key to selecting the right Current Transformer (CT) or Potential Transformer (PT) for your application. Here’s a quick overview of the essential parameters:

| Specification | Details |

|---|---|

| Rated Primary Current | From a few amperes up to several kiloamperes (customizable) |

| Rated Secondary Current | Usually 1A or 5A for CTs, standard voltages for PTs |

| Rated Primary Voltage | Up to 36kV or higher for medium voltage units, up to 720V for low voltage |

| Transformation Ratio | Primary to secondary current/voltage ratio as per design |

| Accuracy Classes | Metering: 0.2, 0.5, 1.0; Protection: 5P, 10P, PX |

| Burden Ratings | Available in a wide range of VA ratings to ensure performance |

| Insulation Levels | Meets BIL requirements and power frequency withstand for safe operation |

| Frequency | Designed for 50/60 Hz systems |

| Thermal & Dynamic Ratings | Supports rated and short time currents under thermal stress |

| Operating Temperature | Suitable for various environmental conditions, typically -40°C to +70°C |

| Mounting Options | Includes window type, busbar, rail mounting, and split-core options |

| Physical Dimensions | Compact designs tailored according to application and installation needs |

Our instrument transformers are built to withstand demanding electrical environments with reliable accuracy and robust insulation. For detailed specs on specific models, check out our range of medium voltage current transformers or explore our outdoor current transformers designed for tougher conditions.

Selecting the right combination of these specs ensures your CT/PT units deliver accurate measurements with optimal safety and lifespan, fitting perfectly into your electrical systems.

Applications of Instrument Transformers Products

Instrument transformers products play a crucial role in a wide range of power systems and electrical networks. They are essential for revenue metering and precise energy measurement, ensuring accurate billing and energy management. For protection relaying, including overcurrent, differential, and distance protection schemes, current transformers (CTs) and potential transformers (PTs) / voltage transformers (VTs) provide reliable isolation and signal scaling to safeguard equipment and maintain system stability.

These transformers are seamlessly integrated into switchgear and switchboard systems, enhancing monitoring and control capabilities. Both low voltage (LV) and medium voltage (MV) distribution panels rely on our instrument transformers for accurate sensing and protection functions in industrial control and power distribution setups.

In substation and utility installations, instrument transformers ensure dependable performance for operational safety and system reliability. They also serve motor control centers and power monitoring applications by providing precise current and voltage references needed for efficient operation and fault detection.

For customers seeking comprehensive power distribution solutions, our instrument transformers perfectly complement industrial setups as described in our industrial power distribution & protection and switchgear & substation solutions product lines, supporting a full range of applications in modern power networks.

Standards & Certifications for Instrument Transformers Products

Our instrument transformers products strictly comply with international standards such as IEC 61869 and IEEE C57.13, ensuring reliable performance and safety. Each unit undergoes comprehensive type and routine testing to guarantee accuracy class and burden VA ratings meet specified limits. We also maintain rigorous quality management under ISO 9001, assuring consistent manufacturing quality across all current transformers (CTs) and potential transformers (PTs).

Additionally, our compliance extends to environmental standards, promoting sustainable practices with options like epoxy resin cast insulation and eco-friendly materials. This commitment makes our CT PT products ideal for demanding industrial and utility applications worldwide, where certified and tested instrument transformers are crucial.

For more details on transformer durability and maintenance, explore our guide on how to maintain a dry-type transformer for performance.

Why Choose Kampa Instrument Transformers

Choosing Kampa for your instrument transformers means you get reliable current transformers (CTs) and potential/voltage transformers (PT/VTs) designed for real-world needs. Here’s why Kampa stands out:

| Feature | Benefit |

|---|---|

| Competitive lead times | Fast delivery to meet project schedules |

| Customization | Tailored solutions up to medium voltage (36kV+) |

| Proven HV equipment track record | Trusted by global utilities and industries |

| Comprehensive technical support | Datasheets, manuals, and on-demand help |

| Global supply chain & export | Reliable worldwide shipping and service |

Kampa’s experience with medium voltage current transformers and low voltage instrument transformers ensures you get products that fit precisely, whether it’s for metering CT accuracy classes or protection CT burden VA ratings. Plus, all transformers comply with international standards to maintain consistency and safety.

Explore tailored solutions and detailed product specs with Kampa’s expertise for your next project — backed by strong technical data and a global network. For more on our voltage transformers, visit our voltage transformers product range page.

Product Selector / Comparison Table

To help you choose the right instrument transformers products, here’s a quick comparison of our key models based on voltage class, accuracy, burden, mounting style, and primary ratings:

| Model | Voltage Class | Accuracy Class | Burden VA Rating | Mounting Type | Primary Current/Voltage |

|---|---|---|---|---|---|

| Kampa CT-WT Series | Low & Medium Voltage (up to 36kV) | 0.2, 0.5 (Metering), 5P, 10P (Protection) | Up to 30 VA | Window Type, Busbar Mounting | 5 A to 600 A |

| Kampa PT/VT Series | Low Voltage (up to 720 V) | 0.2, 0.5 (Metering) | Up to 15 VA | Rail Mounting, Indoor | 120 V to 720 V |

| Combined CT/PT Units | Custom Medium Voltage (up to 36 kV+) | 0.5, 1.0 (Metering), 5P, PX (Protection) | 15 to 30 VA | Epoxy Resin Cast, Oil-Paper | Various |

| Split-Core CT | Low Voltage Instruments | 1.0, 5P (Protection) | Up to 10 VA | Split-Core Clamp On | 50 A to 500 A |

Key Tips:

- Choose accuracy class based on purpose: metering requires 0.2 to 1.0, protection uses 5P or 10P classes.

- Match burden VA rating to your load for stable measurements and device protection.

- Consider mounting options for your installation environment: busbar for substations, rail for panel boards.

- Primary ratings must align with system current or voltage to ensure safety and proper operation.

Keep in mind, our instrument transformers are designed to work seamlessly with medium voltage equipment like vacuum circuit breakers — check related products such as the ZW7-40.5 outdoor high voltage vacuum circuit breaker for integrated project compatibility.

Use this quick guide to narrow down your selection and find the ideal CT/PT product that meets your system needs, ensuring accuracy, reliability, and compliance with standards.

Downloads & Resources for Instrument Transformers

Access all essential instrument transformers products information in one place to help with your selection, installation, and maintenance.

| Resource Type | Description |

|---|---|

| Product Catalog PDFs | Complete overview of CT, PT, and VT models |

| Technical Datasheets | Detailed specs: accuracy class, burden VA |

| Installation Guides | Step-by-step mounting and wiring instructions |

| Maintenance Guides | Tips for long service life and low upkeep |

| Selection Guide for CT/PT | Helps choose the right current and voltage transformers |

We update all documentation regularly to reflect new standards and product improvements. Download these resources to ensure you get the best fit for your medium voltage current transformers and low voltage instrument transformers needs.

For transformer solutions beyond instrument transformers, explore related products like our oil-immersed distribution transformer for integrated power equipment.

FAQ Section: Instrument Transformers Selection & Use

Here are answers to some common questions about instrument transformers products, especially Current Transformers (CTs) and Potential Transformers (PTs) or Voltage Transformers (VTs):

1. How do I choose between metering and protection current transformers?

Metering CTs focus on high accuracy (0.2, 0.5, 1.0 accuracy classes) for billing and energy measurement. Protection CTs have wider accuracy ranges (5P, 10P, PX) to detect faults reliably. Select based on your need—precise measurement vs. fast, dependable fault detection.

2. What should I consider for burden VA rating?

The burden rating means how much load the CT or PT can handle without accuracy loss. Always pick a burden rating higher than the total connected devices’ VA to ensure stable and accurate readings.

3. How to interpret CT/PT accuracy classes?

Accuracy classes define how close the output current or voltage matches the input under specific conditions. For example, a 0.2 class CT means up to 0.2% error, ideal for accurate metering.

4. What are the installation best practices? Ensure secure mounting, considering window type, busbar, or rail mounting as needed.

Correctly orient the polarity marks on CTs and PTs to avoid measurement errors.

Keep wiring short and neat to reduce interference.

Follow insulation and clearance guidelines especially for medium voltage units. 5. Can I retrofit split-core CTs easily?

Split-core CTs are great for adding metering without disrupting existing connections because they clamp around an existing conductor.

6. What’s the difference between low voltage and medium voltage instrument transformers?

Low voltage (up to 720V) instruments suit smaller installations and control panels. Medium voltage CTs and PTs (up to 36kV or customized levels) are designed for substations and heavy industrial setups, with robust insulation and build quality.

7. How to calculate transformation ratios?

The ratio depends on your primary circuit. For example, a 1000:5 CT reduces 1000A in the primary to 5A in the secondary, compatible with standard meters and relays.

If you want more on installation or dry-type transformer integration, check our guides on dry-type transformer types and their applications and options like Eaton dry-type transformers.

Feel free to reach out for specific questions about your instrument transformer needs or custom solutions.

Get in Touch for Instrument Transformers Products

Ready to find the perfect instrument transformers products for your project? Whether you need current transformers, potential transformers, or combined CT/PT units for low voltage or medium voltage applications, we’re here to help.

| How We Can Help | Details |

|---|---|

| Request a Quote | Fast, tailored pricing for your specs |

| Custom Design Inquiries | Solutions built around your needs |

| Live Chat | Instant answers from our technical team |

| Technical Consultation | Expert advice on accuracy classes, burden ratings, and installation |

Contact us today through our easy-to-use form or start a live chat for quick support. Our team is ready to assist you with metering current transformers, protection current transformers, and more – ensuring you get reliable, high-quality products that fit your exact requirements.