If you’re searching for detailed dry type transformer specifications, you’ve come to the right place. Whether you’re an electrical engineer, procurement specialist, or facility manager, understanding the key parameters like kVA ratings, insulation class, cooling methods, and efficiency is crucial for selecting the perfect transformer for your project. This guide cuts through the technical jargon to help you decode essential specs, compare options like cast resin and vacuum pressure impregnated transformers, and navigate standards such as IEC 60076-11. Ready to make informed decisions backed by solid data and reliable supplier insights? Let’s dive into everything you need to know about dry type transformer specifications.

Understanding Dry Type Transformer Basics

Definition and Operating Principle

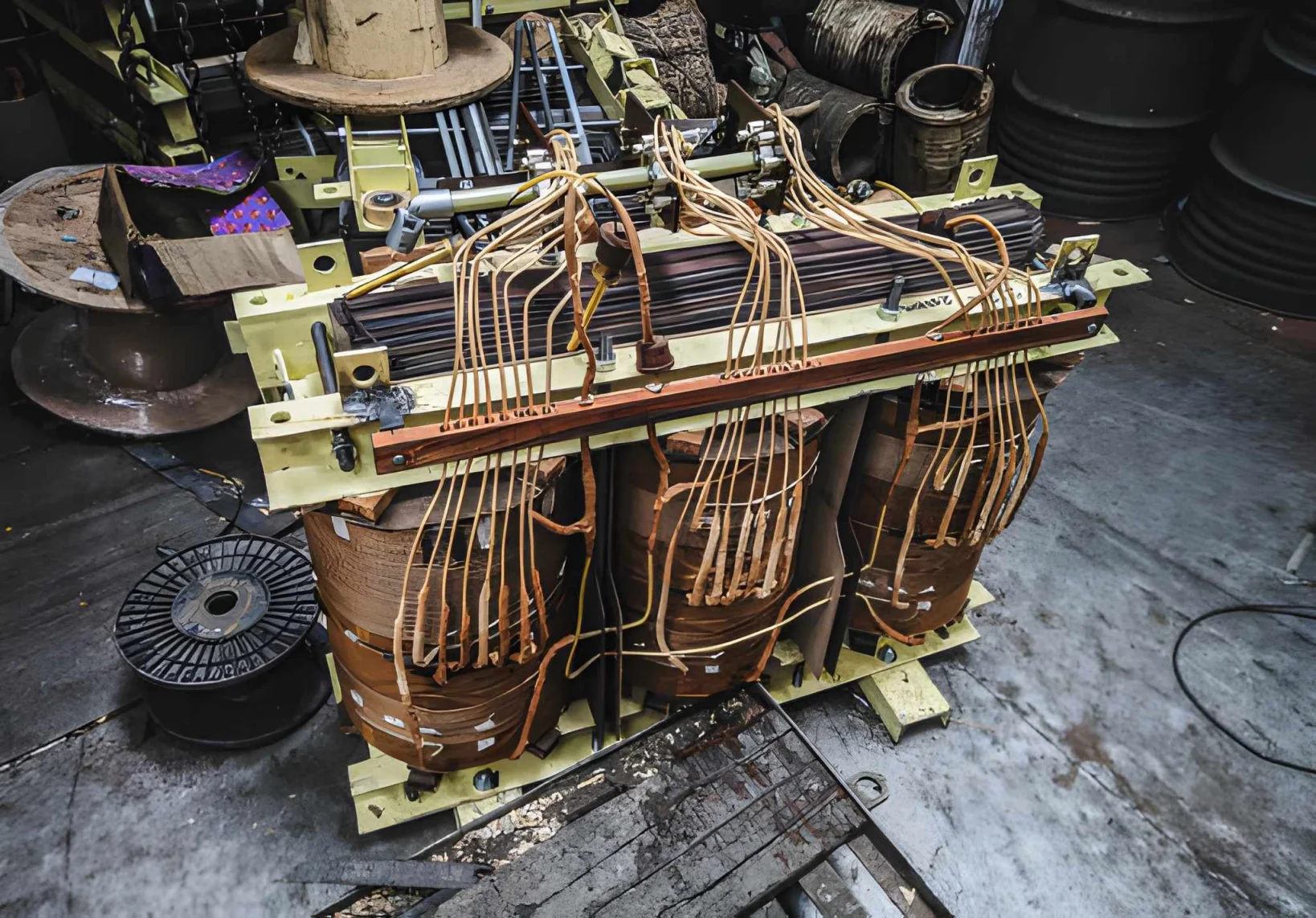

A dry type transformer is an electrical device that transfers power between circuits without using liquid insulation like oil. Instead, it relies on air for cooling and solid insulation materials such as epoxy resin or varnish. These transformers operate on electromagnetic induction, where a magnetic core and primary and secondary windings transfer voltage and current safely.

Comparison with Oil-Filled Transformers

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Medium | Air | Oil |

| Fire Risk | Low | Higher due to flammable oil |

| Maintenance | Minimal | Regular oil checks and testing |

| Environmental Impact | Eco-friendly, no oil spills | Risk of oil leaks & contamination |

| Installation Location | Suitable indoors and sensitive areas | Often located outdoors or in substations |

| Size and Weight | Typically larger and heavier | More compact for same rating |

Common Types of Dry Type Transformers

- Cast Resin Dry Type Transformer: Uses epoxy resin for insulation; excellent for damp or polluted environments.

- Vacuum Pressure Impregnated (VPI) Transformer: Windings are impregnated with varnish under vacuum, improving insulation and moisture resistance.

- Open-Wound Transformer: Simple construction with exposed coils; used where environment is controlled.

Each type offers specific benefits depending on insulation needs, cooling, and application demands. Choosing between these depends on your facility’s environment, safety requirements, and performance expectations.

Key Specifications Explained

Understanding the key specifications of a dry type transformer helps ensure you pick the right one for your needs. Here’s a quick breakdown of what to consider:

| Specification | Description |

|---|---|

| Rated Power (kVA) | Defines the maximum load the transformer can handle continuously. Common ratings range widely. |

| Voltage Classes | Specifies primary and secondary voltages to match your system requirements. |

| Insulation Classes | Materials rated for temperature, e.g., Class F (155°C), Class H (180°C), dictating durability. |

| Temperature Rise Limits | Maximum allowable winding temperature rise during operation (typically 80°C to 115°C). |

| Cooling Methods |

- AN: Air Natural (no fans)

- AF: Air Forced (fans used)

- ANAF: Combined cooling, natural plus forced air

Determines heat dissipation and overload capacity. |

| Overload Capabilities | Defines how much and how long the transformer can exceed rated load safely. |

| — | — |

| Impedance | Affects voltage drop and short circuit current; generally expressed as a percentage. |

| Short Circuit Withstand | Ability to survive mechanical stresses during short circuits without damage. |

| Basic Impulse Level (BIL)| Measures the transformer’s resistance to high voltage surges such as lightning strikes. |

| Partial Discharge | Indicates insulation quality; lower levels mean better reliability and less chance of faults. |

| Efficiency and Losses | Dry type transformers are efficient but have core and copper losses; efficiency usually >97%. |

| Frequency | Standard frequencies are 50Hz or 60Hz depending on the region. |

| Vector Group | Defines winding connections and phase displacement, important for system compatibility. |

These specs directly impact performance, reliability, and suitability. For example, higher insulation classes enable higher temperature rise limits, allowing for more compact designs or greater overload tolerance. Cooling methods like Air Forced (AF) enhance capacity but may increase maintenance.

For detailed performance under specific loads or environments, choosing the right combination of these specs is key to optimizing your dry type transformer’s life and efficiency.

If you’re evaluating transformers alongside switchgear, also check out products like the VSG-12 indoor high voltage vacuum circuit breaker for integrated power system solutions.

Environmental and Performance Classes

When specifying a dry type transformer, considering its environmental and performance classes is crucial for long-term reliability and safety.

Climatic Classes for Temperature and Humidity

Dry type transformers are designed to handle various climatic conditions. Their temperature and humidity ratings dictate where they can be installed, from dry, controlled indoor spaces to more challenging environments. These climatic classes ensure the transformer operates efficiently without overheating or moisture damage.

Pollution Levels and Fire Safety Classes

Pollution categories indicate how resilient a transformer is against dust, chemicals, and other contaminants. Dry type transformers are often rated to withstand pollution levels common in urban or industrial areas. Additionally, fire safety classes focus on minimizing fire risks—the non-flammable insulation materials in cast resin and vacuum pressure impregnated (VPI) transformers improve safety where fire hazards are a concern.

Enclosure Ratings and Indoor/Outdoor Suitability

The IP (Ingress Protection) rating gives a clear idea of a dry type transformer’s resistance to solids and liquids. Higher IP ratings are essential for outdoor installations or harsh industrial sites. Most dry type transformers are designed primarily for indoor use but can be customized with suitable enclosures to meet outdoor and high-pollution area demands.

Understanding these environmental and performance classes helps ensure the dry type transformer meets your site-specific needs for safety, durability, and regulatory compliance. For examples of cast resin dry type transformers with robust environmental ratings, check out Kampa’s indoor cast resin current transformers.

Design and Construction Features

Dry type transformers are carefully designed for safety, performance, and longevity. Here’s a quick breakdown of the main construction elements:

Core Materials and Construction Techniques

- Core: Usually made from high-quality silicon steel laminations to reduce losses and improve magnetic properties.

- Construction: Core is either stacked or wound, with precise assembly to minimize noise and vibration.

Winding Materials and Insulation Systems

- Winding: Copper or aluminum conductors are used, with copper offering better conductivity but at a higher price.

- Insulation: Advanced insulation systems like epoxy resin (cast resin types) or vacuum pressure impregnated (VPI) tapes protect the windings, ensuring a strong dry type transformer insulation class and high temperature rise tolerance.

Tap Changers and Voltage Adjustment

- Tap changers allow fine adjustment of output voltage to maintain steady performance under varying load conditions. They can be:

- Off-load tap changers (OLTC)

- Load tap changers (LTC)

This flexibility is crucial for applications sensitive to voltage fluctuations.

Accessories: Temperature Monitors, Fans, Surge Arresters

- Temperature Monitors: Sensors track winding and ambient temperatures to prevent overheating.

- Fans: Used in Air Forced (AF) or Air Natural + Forced (ANAF) cooled transformers for better heat dissipation.

- Surge Arresters: Protect transformer windings from voltage spikes and ensure reliability.

| Feature | Description |

|---|---|

| Core Material | Silicon steel laminations |

| Winding Material | Copper or aluminum |

| Insulation System | Cast resin or Vacuum Pressure Impregnated (VPI) |

| Tap Changers | Off-load and load tap changers |

| Temperature Control | Sensors for thermal monitoring |

| Cooling Accessories | Fans for AF/ANAF cooling |

| Protection Devices | Surge arresters |

These design choices ensure dry type transformers deliver high efficiency, withstand short circuit stresses, and meet key international standards like IEC 60076-11.

For more on dry type transformer insulation and protection, explore models such as the JDZX9-35 single-phase hermetically casted insulation voltage transformer.

Standards and Compliance

Dry type transformers must meet strict international standards to ensure safety, performance, and reliability. The primary standards include:

| Standard | Description |

|---|---|

| IEC 60076-11 | Defines requirements for dry type transformers globally |

| IEEE C57 Series | US-based standards focusing on design, testing, and rating |

| UL Certification | Safety certification mainly for North American markets |

| CSA Certification | Canadian safety and performance standard |

| KEMA Certification | European third-party testing and certification |

Energy Efficiency and Testing

Efficiency standards are critical due to growing energy regulations. Dry type transformers undergo routine loss and efficiency testing to comply with local and international mandates. This includes checking temperature rise limits, insulation integrity, and short circuit withstand capabilities.

Why It Matters

- Safety: Certified transformers reduce fire risks and electrical hazards.

- Performance: Compliance ensures consistent operation under rated loads.

- Market Access: Certified products can be sold worldwide without restrictions.

At Kampa, we ensure all dry type transformers meet or exceed these standards, delivering reliable products that align with the latest regulations. This focus guarantees safety and efficiency in every unit we supply.

For more on related products and insulation standards, explore our dry type transformer insulation series.

How to Select the Right Dry Type Transformer

Choosing the right dry type transformer means balancing your power needs, environment, and budget. Here’s a straightforward guide to help:

Step-by-Step Selection Guide:

- Determine Rated Power (kVA): Start with the total load your transformer must handle. Always factor in future load growth or peak demand to avoid undersizing.

- Check Voltage Classes: Ensure compatibility with your supply and load voltages, including primary and secondary voltage ratings.

- Consider Overload Factors: Dry type transformers typically tolerate light overloads for limited time. Define your overload allowance and select a transformer with adequate thermal margin.

- Choose Cooling Method: Options like Air Natural (AN), Air Forced (AF), or a combination (ANAF) affect performance. Select based on heat dissipation needs and installation environment.

Sizing and Overload Considerations:

- Account for continuous and transient loads.

- Confirm insulation class and temperature rise capacity match your operational conditions.

- Select impedance and short circuit withstand levels suitable for system protection.

Common Applications:

Dry type transformers fit many sectors including commercial buildings, data centers, hospitals, renewables, and industrial plants. Their compact design and safety profile make them ideal where fire risk or environmental hazards are a concern.

For a deeper dive on selecting dry type transformers that precisely fit your project’s needs, explore our detailed step-by-step guidance at how to select the right dry type transformers for your project.

This approach ensures you get the best mix of efficiency, durability, and cost-effectiveness, tailored to your unique application.

Customization Options with Kampa

Kampa offers extensive dry type transformer customization options to meet your exact needs. We tailor designs based on your required voltage, kVA ratings, and cooling methods—whether you prefer cast resin, vacuum pressure impregnated (VPI), or other dry type transformer types.

What You Can Customize:

| Feature | Options Available |

|---|---|

| Voltage Classes | Low, medium, and high voltage up to 36kV |

| kVA Ratings | From small distribution to large industrial sizes |

| Cooling Methods | AN (Air Natural), AF (Air Forced), ANAF (Air Natural + Forced) |

| Materials | Copper or aluminum windings; various core steel grades |

| Enclosure Types | IP20 to IP54, indoor and outdoor ratings |

| Accessories | Temperature monitors, fans, surge arresters |

Kampa’s competitive pricing and fast delivery make these tailored dry type transformer solutions accessible without compromising quality. Our ability to adjust product specs lets you get exactly what fits your application, whether it’s for a data center, hospital, or industrial site.

Explore our offerings, including high-quality voltage transformers like the JDZ10-3.6/10 A/B single-phase fully insulated casting voltage transformer to complement your system.

Choose Kampa for flexible, reliable, and efficient dry type transformer solutions built around your project’s needs.

Maintenance and Long-Term Performance

Dry type transformers require minimal maintenance compared to their oil-filled counterparts. Thanks to their sealed, dry insulation systems like cast resin or vacuum pressure impregnated windings, routine upkeep is straightforward and less frequent. Regular visual inspections, cleaning to remove dust or debris, and periodic temperature monitoring are usually enough to ensure reliable operation.

For monitoring, installing temperature sensors or fans can help prevent overheating and extend the lifespan. Troubleshooting is easy; common issues often relate to partial discharges or insulation wear, which can be detected early through condition monitoring equipment.

Typically, a well-maintained dry type transformer enjoys a service life of 30 to 40 years. Most manufacturers back this with warranties covering materials and workmanship, giving confidence in long-term performance. To maximize value, choose transformers with proven durability and consider suppliers offering ongoing support and warranty services.

For specific transformer models and their maintenance considerations, exploring products such as the CKJ5 horizontal dry type transformer provides insight into design features that ease upkeep while maintaining efficiency.

Installation, Operation, and Testing

Proper installation and operation are vital for reliable dry type transformer performance. Following the right procedures helps avoid downtime and extends transformer life.

Site and Mounting Requirements

- Location: Dry type transformers work best in clean, dry, well-ventilated areas, free from dust and corrosive gases.

- Mounting: Secure on a solid, level foundation to avoid vibrations. Use anti-vibration pads if necessary.

- Clearances: Maintain recommended clearances for airflow and maintenance access.

- Enclosure: Ensure the enclosure rating (IP rating) suits indoor or outdoor use, protecting against moisture and pollution.

Testing Procedures and Routine Checks

Before energizing, conduct these essential tests:

| Test Type | Purpose | Frequency |

|---|---|---|

| Insulation Resistance Test | Ensures no insulation breakdown | Before commissioning |

| Turns Ratio Test | Confirms correct winding ratio | At installation |

| Winding Resistance Test | Checks winding integrity | During commissioning |

| Power Factor Test | Verifies insulation health | Periodic |

| Partial Discharge Test | Detects early insulation defects | According to standards |

Routine checks should include:

- Monitoring temperature and noise levels during operation

- Inspecting for dust or moisture buildup

- Verifying cooling systems (fans, ventilation) function properly

- Checking accessories like temperature monitors and surge arresters

For specialized switchgear and substation solutions that complement transformer setups, consider exploring detailed options from Kampa Electric’s switchgear and substation solutions.

Following these installation and testing steps ensures your dry type transformer operates safely and efficiently from day one.

Applications and Advantages of Dry Type Transformers

Dry type transformers are a smart choice in many sectors due to their safety, reliability, and low maintenance. Popular applications include:

- Data Centers: Provide efficient, fire-safe electrical power distribution.

- Hospitals: Offer clean power with low electromagnetic interference.

- Commercial Buildings: Ideal for indoor installation with minimal fire risk.

- Renewable Energy Sites: Handle fluctuating loads from solar and wind power setups.

Dry Type vs Oil-Filled Transformers

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Fire Risk | Low (no oil involved) | Higher due to flammable oil |

| Maintenance | Minimal; no oil checks or replacements | Regular oil testing and changing needed |

| Environmental Impact | Eco-friendly; no risk of oil leaks | Potential soil and water contamination |

| Cooling Method | Air cooling (AN, AF, ANAF) | Oil cooling with radiator systems |

| Installation Location | Indoor/outdoor with proper enclosures | Mainly outdoor or well-ventilated indoor |

| Size and Weight | Generally larger and heavier | More compact for the same power rating |

Load Calculations and Future Proofing

When sizing dry type transformers, consider:

- Expected Load Growth: Design for 10-20% future overload capacity.

- Load Type: Account for non-linear loads common in data centers and hospitals.

- Operating Environment: Temperature and humidity affect transformer life.

- Energy Efficiency Needs: Higher efficiency models may cost more upfront but save energy long-term.

These points ensure your transformer investment lasts and adapts as your power needs evolve.

Dry type transformers stand out for their safety, energy efficiency, and adaptability—making them a preferred option in sensitive environments. For a detailed look at the differences and advantages, you can explore our insights on dry type vs oil immersed transformers for industrial applications.

Pricing and Supplier Guidance

When considering a dry type transformer, pricing often depends on several key factors:

- Rated Power (kVA): Higher kVA ratings generally increase cost due to larger materials and design complexity.

- Voltage Classes: Transformers built for higher voltages require more insulation and stricter design standards.

- Cooling Methods: Options like AN (Air Natural), AF (Air Forced), or ANAF (Air Natural/Forced) can impact pricing based on complexity.

- Customization: Tailored solutions for specific voltage, enclosure (IP ratings), or environmental requirements can add to the cost.

- Materials and Design: Using premium core materials, cast resin, or vacuum pressure impregnated (VPI) winding methods influences the price point.

- Standards Compliance: Meeting international standards such as IEC 60076-11 or certifications like UL and CSA may increase cost but ensures reliability.

Kampa specializes in custom dry type transformer designs that balance quality and budget, offering competitive pricing without compromising performance. Our extensive case studies demonstrate how we optimize material choices, cooling methods, and insulation systems to deliver cost-effective solutions tailored for various industries. For reliable and efficient transformers, exploring Kampa’s custom solutions and comprehensive support ensures you get the right product for your needs without overspending.

Discover more about Kampa’s expertise as a leading dry type transformer supplier for reliable power solutions and explore our range of medium and high voltage power solutions.