How Dry-Type Power Transformers Work

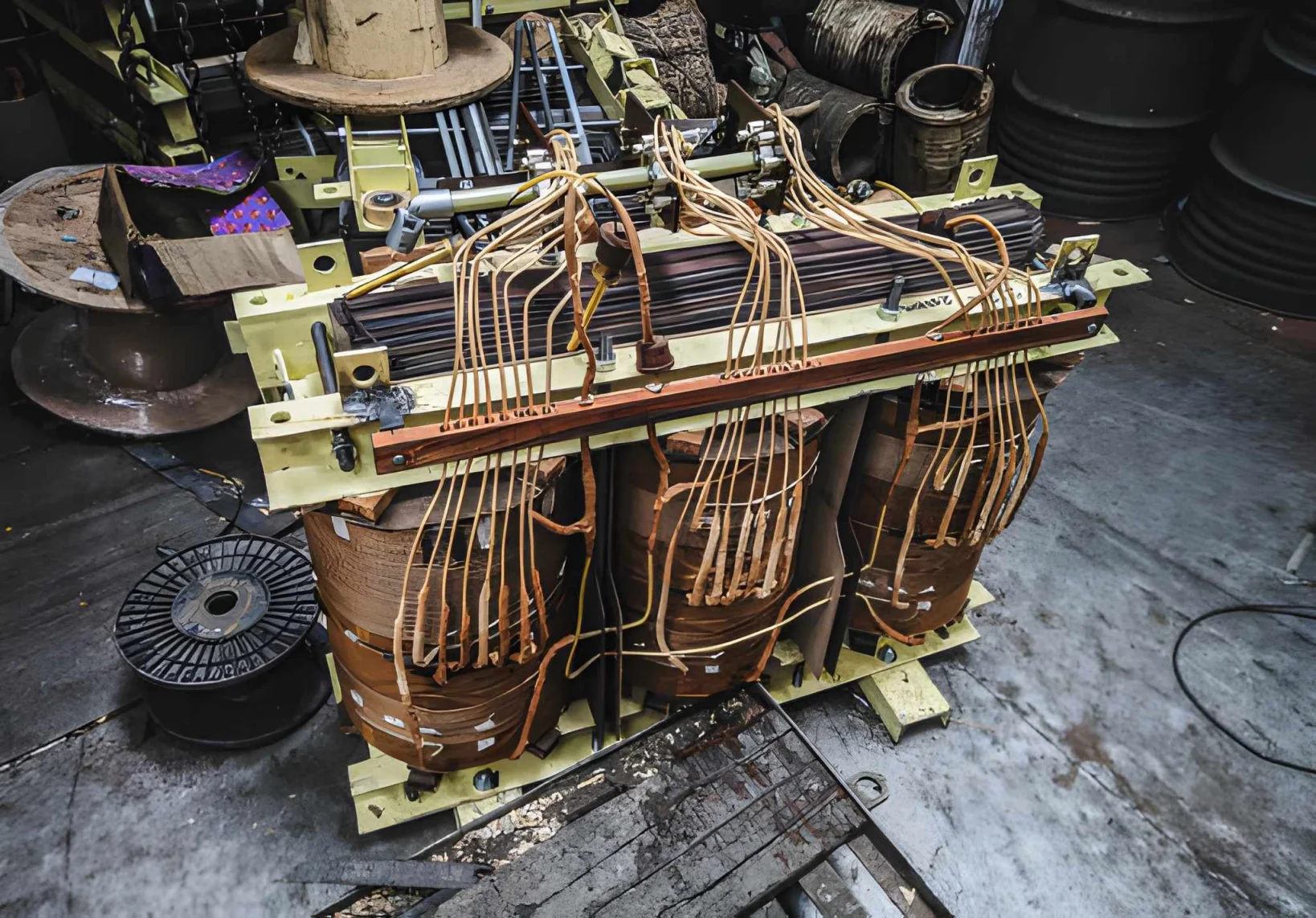

Dry-type power transformers operate on the core principles of electromagnetic induction, just like any basic transformer. They consist of two main components:

- Primary winding: Receives the incoming voltage

- Secondary winding: Delivers transformed voltage to the load

- Core: Usually made of laminated silicon steel, guiding magnetic flux efficiently

When an alternating current flows through the primary winding, it creates a magnetic field in the core, inducing a voltage in the secondary winding. This process adjusts voltage levels for various applications.

Core Construction and Windings

- Core: Laminated to reduce energy losses by minimizing eddy currents

- Windings: Made from copper or aluminum, insulated to avoid short circuits

- Insulation: Typically varnish, epoxy resin, or vacuum pressure impregnated (VPI)

Cooling Mechanisms: Natural vs. Forced Air Cooling

Dry-type transformers rely on air as the cooling medium, which can be managed in two primary ways:

| Cooling Method | Description | Typical Use |

|---|---|---|

| Natural Air Ventilation | Heat dissipates through free air circulation around the transformer | Small to medium loads |

| Forced Air Cooling | Fans or blowers increase airflow to cool the windings effectively | Larger, high-power units |

These air-cooled power transformers avoid the use of oil or other liquids, enhancing safety and environmental friendliness.

Basic Transformer Operation vs. Dry-Type

| Feature | Dry-Type Transformer | Basic (Oil-Immersed) Transformer |

|---|---|---|

| Cooling | Air-cooled (natural or forced ventilation) | Oil-cooled with radiators |

| Fire Risk | Low (no flammable liquids) | Higher (oil is flammable) |

| Maintenance | Lower due to no oil handling | Higher, includes oil testing and replacement |

| Installation Flexibility | Indoor and space-saving | Usually outdoor or dedicated rooms |

In essence, dry-type transformers deliver the same electrical function as basic transformers but with enhanced safety and cleaner operation, making them ideal for indoor applications and sensitive environments.

Types of Dry-Type Power Transformers

Dry-type power transformers come in several types, each designed to meet specific needs and environments. The most common are Vacuum Pressure Impregnated (VPI) and Cast Resin transformers.

Vacuum Pressure Impregnated (VPI) Transformers use a process where the windings are soaked with insulating varnish under vacuum and pressure. This creates a solid, moisture-resistant insulation that enhances durability and electrical performance. VPI transformers are often chosen for industrial settings because they handle higher loads well and offer good thermal stability.

Cast Resin (Epoxy Encapsulated) Transformers have windings fully encapsulated in epoxy resin. This type provides excellent protection against moisture, dust, and chemicals, making them ideal for harsh indoor environments or places with high humidity. Their rugged construction delivers superior safety and longer service life, especially in fire-prone or hazardous areas.

There are also Open Wound Dry-Type Transformers, where the windings are exposed but insulated. These are generally used in cleaner, controlled environments and allow for easier inspection and cooling but require more careful maintenance.

When selecting the right type, consider the operating environment and load demands. For example:

- Choose VPI transformers for heavy industrial applications needing robust performance.

- Opt for Cast Resin transformers where extra protection from dust, moisture, or fire risk is essential.

- Consider Open Wound transformers in well-ventilated, low-contamination areas.

To help you make the best choice for your project, explore our detailed guide on how to select the right dry-type transformers based on your environment and load requirements. This resource covers all these variants thoroughly and offers expert advice tailored to your needs.

Key Advantages of Dry-Type Power Transformers

Dry-type power transformers offer several advantages that make them a preferred choice for many applications. Their design eliminates the need for flammable oils, significantly reducing fire risks and enhancing overall safety. Because they don’t use oil, there’s no chance of leaks or spills, making them an eco-friendly power transformer option with no toxic emissions.

Maintenance is straightforward and less frequent compared to oil-filled types, thanks to their robust and simple construction. Dry-type transformers are well-suited for indoor installation, saving space with their compact design while operating quietly—a key benefit in noise-sensitive environments like hospitals and data centers.

Additionally, they are more resistant to moisture and dust, which helps maintain long service life and reliable performance over time. These features combine to make dry-type transformers a low maintenance, safe, and environmentally responsible solution for modern power distribution needs.

For more details on how these benefits compare with traditional oil transformers, you can check out Kampa’s detailed comparison of dry-type transformers vs. oil-immersed transformers to see which fits your needs best.

Dry-Type vs. Oil-Immersed Transformers: A Detailed Comparison

Here’s a clear side-by-side breakdown of dry-type power transformers versus oil-immersed transformers across key factors:

| Feature | Dry-Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Cooling Method | Air cooled (natural or forced ventilation) | Oil cooled (natural or forced circulation) |

| Safety | Fire-resistant, no flammable liquids | Contains flammable oil, higher fire risk |

| Maintenance | Low maintenance, no oil handling | Regular oil checks and replacements needed |

| Cost | Generally higher upfront cost | Usually lower initial cost |

| Efficiency | Slightly lower efficiency due to air cooling | Higher efficiency with oil cooling |

| Installation | Flexible indoor installation, compact size | Often requires outdoor space and containment |

| Environmental | Eco-friendly, no risk of oil leaks | Risk of oil spills and environmental hazards |

| Noise Level | Quiet operation | Usually noisier due to oil pump and cooling |

When to Choose Dry-Type Transformers

- Indoor use with limited space or strict fire safety rules.

- Environments sensitive to pollution and spills.

- Applications needing low maintenance and quiet operation (e.g., hospitals, schools).

When Oil-Immersed Transformers Are Preferred

- Heavy-load industrial plants requiring high efficiency.

- Outdoor installations where space and ventilation are not restricted.

- Situations where upfront cost savings are a priority.

For those evaluating transformer options, it’s worth considering both performance and site requirements to pick the best fit. Dry-type transformers, such as the Indoor Cast Resin Current Transformers, offer excellent safety and environmental benefits ideal for many modern applications.

Technical Specifications and Selection Criteria

When choosing a dry-type power transformer, several technical specs are crucial to match your exact needs, especially for global markets requiring reliability and efficiency.

Common Ratings

- kVA range: Typically from 10 kVA up to several thousand kVA for medium voltage dry transformers.

- Voltage levels: Usually available from low voltage (up to 1 kV) to medium voltage (up to 36 kV).

- Temperature rise: Often rated at 80°C or 115°C to ensure safe operation under load.

Insulation Classes

- Common insulation classes include Class F (155°C) and Class H (180°C), offering higher thermal endurance for longer lifespan.

Standards Compliance

Dry-type power transformers often meet key standards such as:

- IEC (International Electrotechnical Commission)

- ANSI (American National Standards Institute)

- IEEE (Institute of Electrical and Electronics Engineers)

These certifications guarantee safety, performance, and quality.

Load and Efficiency

- Select based on load demands, harmonics, and transient conditions.

- Efficiency levels typically range from 95% to above 99%, with premium designs focusing on reducing energy losses.

Enclosure Types and IP Ratings

- Enclosures protect against dust, moisture, and physical damage. Common IP ratings for indoor transformers:

- IP23: Protection against dripping water and dust.

- IP44: Better dust protection and splash resistance for harsher environments.

| Specification | Typical Range/Value | Notes |

|---|---|---|

| kVA Rating | 10 kVA – 3000+ kVA | Based on load requirements |

| Voltage Levels | Up to 36 kV (Medium Voltage) | Varies with application |

| Temperature Rise | 80°C, 115°C | Determines transformer cooling |

| Insulation Class | Class F (155°C), Class H (180°C) | Higher class for tough conditions |

| Efficiency | 95% – 99%+ | Energy-saving designs |

| Enclosure IP Rating | IP23, IP44 | Environmental protection |

| Compliance Standards | IEC, ANSI, IEEE | Safety and performance standards |

Choosing the right dry-type transformer means balancing these specs with your specific application, from commercial buildings to industrial sites. For customized solutions with reliable voltage transformers, consider options like Kampa’s epoxy resin voltage transformers to fit precise requirements.

Applications of Dry-Type Power Transformers

Dry-type power transformers are widely used across various sectors due to their safety, reliability, and low maintenance. You’ll often find them in commercial buildings, hospitals, schools, and data centers, where clean and safe indoor power is essential. Their fire-resistant design and quiet operation make them perfect for these environments.

In the industrial realm, dry-type transformers serve chemical plants, manufacturing facilities, and renewable energy sites. Their durability and ability to handle variable loads make them ideal for demanding industrial conditions. Additionally, they’re trusted in infrastructure projects like tunnels, offshore platforms, and urban substations where space and environmental safety are critical.

With the rise of smart grids and renewable energy, dry-type transformers are gaining traction in renewable integration and advanced grid applications. They offer eco-friendly, oil-free operation suited for modern energy systems.

For more insight into how these transformers adapt to industrial applications, explore the detailed overview of dry-type transformers for industrial applications.

Installation, Maintenance, and Best Practices for Dry-Type Power Transformers

When installing dry-type power transformers, choosing the right site and enclosure is critical. These transformers thrive in clean, dry, and well-ventilated areas. Depending on your environment, enclosed options with appropriate IP ratings can protect against dust, moisture, and other contaminants, ensuring reliable operation. For indoor power transformers, pay attention to space for natural or forced air cooling to maintain optimal temperature levels.

Routine maintenance is straightforward but essential. Regularly inspect for dust buildup, loose connections, or any signs of overheating. Cleaning with dry compressed air works well to remove dust without introducing moisture. Checking insulation resistance and monitoring temperature during operation can catch potential problems early before they lead to failures.

To extend the life of your dry-type transformer, ensure proper ventilation is maintained at all times. Forced air cooling or auxiliary fans can help in environments with limited airflow. Additionally, installing monitoring devices to track temperature, load, and humidity can provide valuable data to inform preventive maintenance and avoid unexpected downtime.

Practice these maintenance steps to enjoy a low maintenance transformer with long service life, delivering efficient and safe power in your facility.

For reliable transformer enclosure options and customized solutions, consider trusted products like those from the VS1 series vacuum circuit breaker, which complement dry-type transformer setups perfectly.

Why Choose Kampa Dry-Type Power Transformers

Kampa offers reliable, high-quality dry-type power transformers designed to meet the diverse needs of global customers. Whether you need customized dry type transformers tailored for specific voltage levels, kVA ratings, or environmental conditions, Kampa delivers precision-made solutions.

Key Benefits of Kampa Dry-Type Transformers

| Feature | Benefit |

|---|---|

| Customization Options | Voltage, enclosure type, kVA, cooling methods adapted to your needs |

| Competitive Pricing | Cost-effective without compromising quality |

| Supplier Support | Responsive service and technical assistance worldwide |

| Safety Focus | Fire-resistant, eco-friendly, and low-maintenance designs |

| Efficiency | High operational efficiency with low losses |

With a firm commitment to safety, efficiency, and customer satisfaction, Kampa ensures every dry-type power transformer performs reliably, whether installed indoors or in challenging environments.

Explore Kampa’s full range of medium and high voltage power solutions designed to fit your power needs precisely and confidently.