What Is a 6kV Dry Type Transformer?

A 6kV dry type transformer is a type of medium voltage transformer designed to step up or step down electrical voltages without using any liquid insulation, like oil. Instead, it relies on solid insulation materials such as epoxy resin, making it safer and cleaner for indoor and sensitive environments.

Basic Working Principle

At its core, this transformer works on electromagnetic induction. When alternating current flows through the primary winding, it creates a magnetic field in the core. This magnetic field induces voltage in the secondary winding, allowing voltage transformation within the 6kV class range.

Voltage Class Explanation

The “6kV” refers to the primary voltage rating, which typically falls between 6,000 volts and 6,600 volts. This voltage class suits many industrial, commercial, and utility applications that require medium voltage distribution. The transformer steps voltage down to a lower level suitable for various equipment or further distribution.

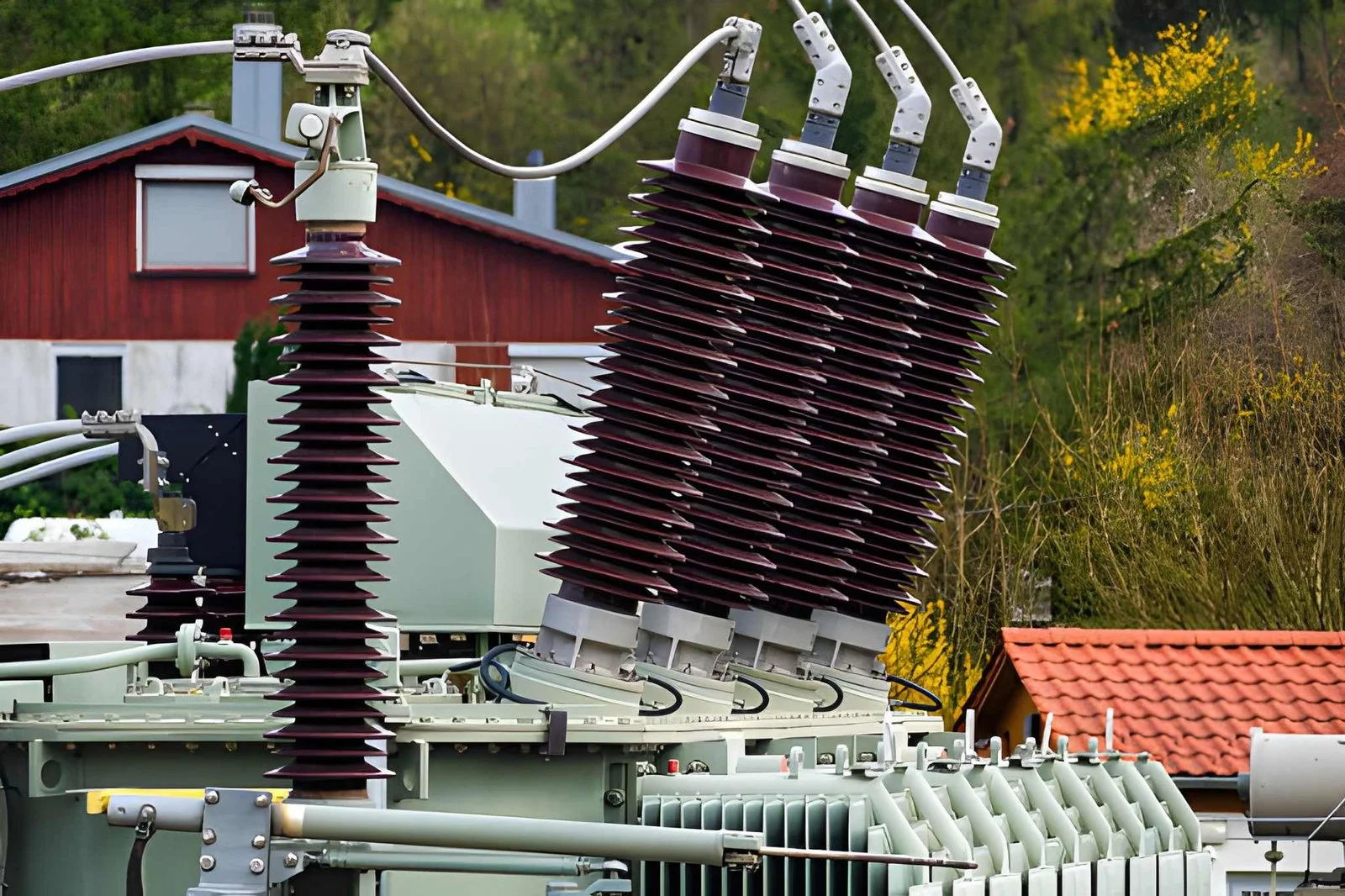

Core Components

A 6kV dry type transformer mainly consists of:

- Windings: Usually made from copper or aluminum, these coils carry the electrical current and are insulated with high-quality materials to withstand voltage stresses.

- Core: Constructed from laminated silicon steel to efficiently guide the magnetic flux and reduce energy losses.

- Insulation System: Uses solid insulation like epoxy resin or vacuum pressure impregnated materials to protect windings and prevent electrical faults.

- Enclosure: A protective casing designed to shield the internal components from dust, moisture, and physical damage, often rated with an IP code (such as IP00 to IP23) based on the environment.

Together, these elements ensure the transformer operates safely and reliably in various medium voltage applications without the risks linked to oil-filled transformers.

Types of 6kV Dry Type Transformers

When it comes to 6kV dry type transformers, there are mainly two popular construction types:

| Transformer Type | Description | Best Suited For |

|---|---|---|

| Cast Resin (Epoxy-Encapsulated) | Windings are fully coated with epoxy resin, making them highly resistant to moisture, dust, and chemicals. This type offers excellent fire safety due to its self-extinguishing properties. | Harsh environments, including industrial sites and places with high humidity or corrosive atmospheres. |

| Vacuum Pressure Impregnated (VPI) | Windings are impregnated with insulating varnish under vacuum and pressure, improving insulation and mechanical strength without a solid resin casing. | Cleaner indoor environments like commercial buildings and data centers where there’s less exposure to contaminants. |

Key Comparison:

| Feature | Cast Resin | VPI |

|---|---|---|

| Insulation | Epoxy resin encapsulation | Varnish impregnated winding |

| Moisture Resistance | Excellent | Moderate |

| Durability | High, tough against chemicals & dust | Good, but less robust outdoors |

| Cost | Generally higher | Often more cost-effective |

| Fire Safety | Superior (no combustible liquids) | Good, but resin adds extra fire protection |

| Weight & Size | Usually heavier | Lighter |

Choosing between these mainly depends on your installation environment and budget. Cast resin transformers excel in tougher conditions with stringent safety rules, while VPI transformers work well where moderate protection is needed without the extra bulk.

For a deeper dive into differences and advantages, you can check out this detailed comparison of dry type transformer vs cast resin.

Key Technical Specifications of 6kV Dry Type Transformers

6kV dry type transformers come with a range of technical specs designed to fit various industrial and commercial needs. Here’s a clear rundown:

| Specification | Details |

|---|---|

| Rated Power Range | 100 kVA to 4000 kVA |

| Voltage Ratings | Primary: 6kV or 6.6kV; Secondary varies |

| Tapping Options | ±2 x 2.5% for voltage adjustment |

| Vector Groups | Commonly Dyn11 or others per needs |

| Insulation Class | Class F (155°C) or Class H (180°C) |

| Temperature Rise | Typically 115°C or 150°C depending on class |

| Impedance | Customizable, usually 4% to 6% |

| Cooling Methods | AN (Air Natural) or AF (Air Forced) cooling |

| Enclosure Ratings | IP00 (open) up to IP23 (protected from dust and water) |

| Compliance Standards | IEC 60076, GB (Chinese National Standards) |

These specs ensure the transformers deliver reliable performance, efficiency, and durability across various environments. For example, cooling options like AN and AF adapt the transformer operation for different load and ambient conditions. Insulation classes F and H provide thermal safety and longer lifespan.

Choosing the right vector group like Dyn11 supports optimized power distribution and load balancing. Meanwhile, flexible tapping options allow fine voltage control for stable power supply.

For detailed information on meeting industrial power distribution needs with medium voltage transformers, consider checking our industrial power distribution and protection solutions.

Advantages of 6kV Dry Type Transformers

6kV dry type transformers offer several clear benefits that make them ideal for modern power distribution needs. One of their biggest advantages is enhanced safety. Since these transformers use no oil, they eliminate fire risks associated with oil leaks or spills. Their insulation materials are low flammability and self-extinguishing, which is crucial for indoor and high-occupancy areas.

They also require minimal maintenance, helping to reduce operational costs over their long service life. Thanks to their dry type construction, they are environmentally friendly—there’s no risk of oil contamination, making them a cleaner option compared to traditional oil-immersed transformers.

The compact design of 6kV dry type transformers fits well in limited spaces, and they perform reliably in humid, polluted, or dusty environments where oil-filled models might fail. Plus, since they don’t need special fireproof vaults or underground oil containment systems, installation costs are generally lower.

These practical benefits make 6kV dry type transformers a smart choice for anyone looking for safe, efficient, and cost-effective medium voltage transformer solutions. For deeper insights, check out Kampa’s expert resources on dry type transformer safety and smart power solutions.

Applications and Use Cases of 6kV Dry Type Transformers

6kV dry type transformers are widely used across various sectors thanks to their safety, reliability, and adaptability. In industrial facilities like manufacturing plants and chemical plants, they provide robust power distribution while handling demanding environments without the risk of oil leaks or fire hazards. Their dry type nature suits harsh industrial conditions where safety and low maintenance are critical.

In commercial buildings such as hospitals, data centers, and high-rise complexes, 6kV dry type transformers ensure stable power with minimal noise and enhanced fire safety. Their compact design fits well in limited indoor spaces, supporting critical equipment reliably.

These transformers are also popular in renewable energy projects and substations, where medium voltage transformers must comply with stringent environmental and safety standards, making dry type transformers a natural choice. Additionally, their immunity to pollution and moisture makes them ideal for indoor and underground installations where fire safety and reduced maintenance are paramount.

For tailored solutions in these applications, exploring Kampa’s range of products ensures compliance with your project requirements, such as the reliable cast resin current transformers designed for indoor medium voltage systems.

Dry Type vs. Oil-Immersed Transformers: A Detailed Comparison

When choosing between a 6kV dry type transformer and an oil-immersed transformer, understanding their key differences can help you pick the right fit for your needs.

| Feature | 6kV Dry Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Safety | No oil, low fire risk, self-extinguishing | Contains flammable oil, higher fire hazard |

| Maintenance | Minimal, no oil checks or replacements | Regular oil testing and maintenance required |

| Environmental Impact | Eco-friendly, no oil leak concerns | Risk of oil leaks and contamination |

| Efficiency | Slightly lower, but close with good design | Generally higher efficiency |

| Overload Capacity | Good short-term overload capability | Can often handle higher overloads |

| Noise Levels | Quieter operation | Typically noisier due to cooling oil flow |

| Lifespan | 25 to 30 years with proper care | 30+ years, but depends on oil condition |

| Installation Cost | Lower – no need for oil containment systems | Higher due to oil handling and safety measures |

| Suitability | Indoor, humid, polluted areas, fire-sensitive spaces | Outdoor and heavy-duty industrial settings |

When to Choose a 6kV Dry Type Transformer

- Fire safety is a priority: Dry type transformers are ideal for buildings like hospitals, schools, and data centers where fire risk must be minimized.

- Low maintenance preference: If you want a transformer that needs less upkeep and no oil changes.

- Environmental concerns: For projects demanding eco-friendly solutions with no leakage risks.

- Indoor or confined spaces: Especially where ventilation is limited, dry type transformers perform better.

- Cost-effective installation: Dry type units reduce expenses related to oil containment and fireproof vaults.

For a deeper dive into transformer types and specifications, checking out detailed guides on dry type transformers and dry type power transformers can be very helpful.

Choosing the right transformer depends on your site conditions and priorities—dry type transformers deliver a good balance of safety, reliability, and low maintenance, especially in medium voltage applications around 6kV.

Factors Influencing Price and Cost Analysis of 6kV Dry Type Transformers

Several factors affect the price of a 6kV dry type transformer, making it important to understand what drives costs when planning your budget.

- kVA Rating: The rated power capacity significantly impacts cost. Transformers between 100kVA and 4000kVA have a wide price range, with larger units naturally costing more due to the increased amount of raw materials and construction complexity.

- Winding Materials: Copper windings typically cost more than aluminum because of better conductivity and durability, but aluminum options can reduce upfront expenses while still meeting performance needs.

- Voltage Class: Transformers designed for higher or specialized voltage classes (like 6kV versus 6.6kV) may involve additional insulation and design requirements, influencing the price.

- Additional Features: Enclosure types rated from IP00 up to IP23, extra cooling systems like fans for AN/AF cooling modes, and accessories such as tapping switches or monitoring devices contribute to cost increases but improve reliability and customization options.

- Typical Price Ranges: For medium-sized distribution transformers, prices can range widely—small units around 100kVA can be relatively affordable, while large 4000kVA units represent a bigger investment. It’s best to consult suppliers for accurate quotes based on exact specifications.

- Long-Term Savings: Although several components add to the initial price, 6kV dry type transformers offer long-term savings through lower maintenance costs, no oil handling, and high efficiency, especially in challenging environments.

Investing wisely means balancing upfront costs with these benefits, ensuring you get a durable and cost-effective power solution. For customized options and pricing tailored to your needs, trusted manufacturers like Kampa offer competitive packages combining quality with affordability.

How to Select the Right 6kV Dry Type Transformer

Choosing the right 6kV dry type transformer starts with assessing your load requirements and site conditions. Know your power needs clearly—this means understanding the kVA rating required, voltage levels, and the nature of the load (whether it is steady or fluctuating). Also, consider the installation environment, like whether it’s indoors, in a humid area, or a place with dust or pollutants.

When selecting, focus on key criteria such as:

- Efficiency: Higher efficiency means lower energy loss and operational cost over time.

- Overload Capability: Some transformers handle temporary overloads better, useful for fluctuating loads.

- Noise Levels: In quiet environments like hospitals or data centers, lower noise transformers are preferred.

Customization also plays a big role. Look for features like:

- Tapping options to adjust voltage precisely

- Enclosures with various IP ratings for different environments

- Special features tailored to your project needs

Working with a reputable supplier like Kampa helps ensure you get precisely what you need. Kampa offers tailored solutions with customization options to fit your application. They also provide expert advice, ensuring compliance with standards and quality assurance, which makes a big difference in both performance and lifespan. For example, their range includes reliable cast resin current transformers designed for medium voltage applications, which can complement your dry type transformer setup perfectly.

By carefully considering these aspects, you’ll select a 6kV dry type transformer that is efficient, durable, and perfectly suited to your operational needs.

Installation, Maintenance, and Best Practices for 6kV Dry Type Transformers

Installing a 6kV dry type transformer starts with thorough site preparation. Ensure the area is clean, dry, and well-ventilated to prevent overheating. The foundation should be sturdy and level to support the transformer’s weight and vibration. Always comply with local electrical codes and ensure proper clearance around the transformer for airflow and maintenance access.

Routine inspection is key to maintaining transformer performance. Regularly check for dust buildup on the windings and core, especially in cast resin or vacuum pressure impregnated models, as dust can reduce cooling efficiency. Cleaning with a dry cloth or low-pressure air is usually sufficient—avoid moisture or solvents that could damage insulation.

Common issues to watch for include unusual noises, overheating, or vibration. These symptoms may indicate loose connections, overloading, or insulation aging. Prompt troubleshooting includes verifying electrical connections, measuring temperature rise, and checking the enclosure’s integrity. Skilled technicians should handle repairs to keep safety risks low.

Safety should always come first during operation. Since 6kV dry type transformers have low flammability and no oil inside, fire hazards are reduced—but electrical shock and arc flash risks remain. Use proper personal protective equipment (PPE), lockout-tagout (LOTO) procedures during maintenance, and always follow manufacturer guidelines.

For reliable installation components, you can check relevant accessories like Kampa’s horizontal dry type transformers or compatible contactors designed to work seamlessly with medium voltage equipment.

By following these installation and maintenance best practices, you ensure your 6kV dry type transformer runs efficiently, safely, and with minimal downtime.

Why Choose Kampa for Your 6kV Dry Type Transformers

Kampa stands out as a trusted supplier for 6kV dry type transformers thanks to its deep expertise in dry type transformer technology. Our focus on quality, customization, and competitive pricing ensures you get a product tailored to your specific power needs without compromise.

What Sets Kampa Apart?

| Feature | Benefit |

|---|---|

| Extensive Dry Type Experience | Proven reliability in medium voltage transformers like 6kV dry type models |

| Custom Design Options | Tapping, enclosure, and cooling customized for your site conditions |

| Competitive Pricing | Cost-effective solutions without sacrificing performance |

| Global Supply Capability | Fast delivery and support worldwide |

| Strong Customer Support | Technical assistance from project to operation |

Whether you need a cast resin transformer or a vacuum pressure impregnated dry type transformer, Kampa’s solutions meet international standards such as IEC 60076 and offer superior safety and durability for industrial and commercial applications.

Partnering with Kampa means you get access to a full range of industrial power solutions and tailored transformers designed to fit your project needs perfectly. Browse our transformer category to find the ideal 6kV dry type transformer for your operation.

FAQs About 6kV Dry Type Transformers

What is the typical lifespan of a 6kV dry type transformer?

A well-maintained 6kV dry type transformer can last 25 years or more. Their robust design, especially with quality insulation like epoxy resin, ensures long service life with minimal performance drop over time.

How well can these transformers handle overloads?

6kV dry type transformers usually tolerate short-term overloads of up to 150% for limited periods without damage, thanks to their strong insulation and cooling options like AN/AF. However, it’s important to follow manufacturer guidelines to avoid reducing lifespan.

Are 6kV transformers more cost-effective than 10kV models?

Generally, 6kV dry type transformers are more cost-effective for medium voltage needs due to simpler installation and lower maintenance. While 10kV models suit higher voltage networks, 6kV units offer a balanced choice for many industrial and commercial applications, often saving on initial and operational costs.

Can Kampa customize 6kV dry type transformers?

Yes, Kampa offers extensive customization options, including tapping ranges, enclosure ratings from IP00 to IP23, cooling methods (AN/AF), and choice of winding materials such as copper. This flexibility helps you get transformers tailored perfectly to your site conditions and load needs.

For more detailed product options, you can explore Kampa’s range of medium voltage transformers designed to meet strict industry standards.